Method for preparing isobutene

A technology of isobutene and butene, applied in the field of isobutene preparation, can solve the problems of high energy consumption and low product purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

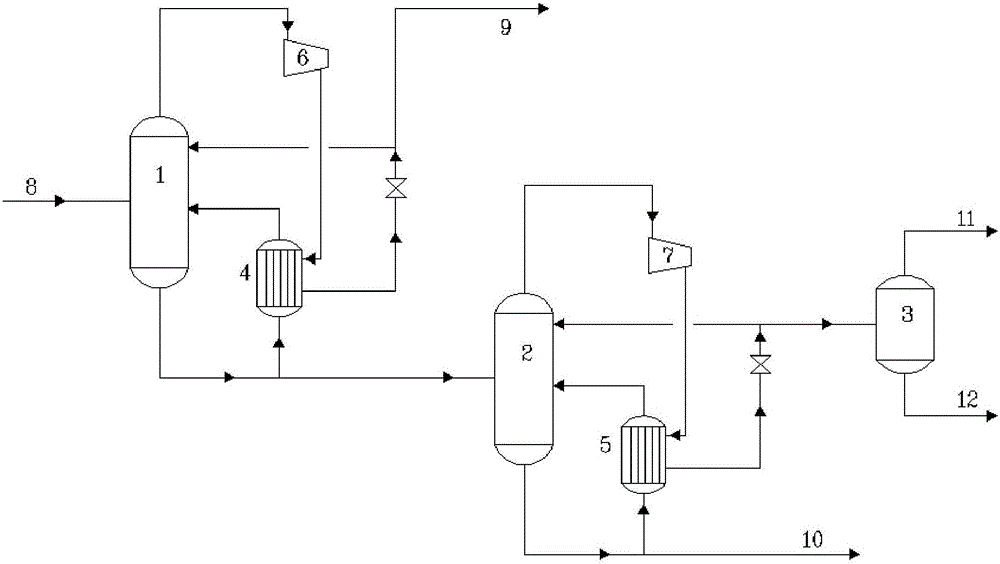

[0029] in such as figure 1In the shown process, firstly, the mixed C4 fraction (8) after hydrogen and light hydrocarbons have been removed mainly includes isobutane, isobutene, 1-butene, n-butane, 2-butene, acetone, water, The material (8) enters the light hydrocarbon removal tower (1) to separate isobutane. Since the difference in boiling point between the light key component of isobutane and the heavy key component of isobutene is 4.9°C, it is carried out by direct compression heat pump rectification process. The components are separated, and the isobutane effluent from the light hydrocarbon removal tower (1) is pressurized and heated by the light hydrocarbon removal tower compressor (6) and is combined with the light hydrocarbon removal tower (1) in the light hydrocarbon removal tower reboiler (4). ) tower kettle material is subjected to heat exchange and cooling, and then further cooled through a throttle valve, a part of which is returned to the light hydrocarbon removal ...

Embodiment 2

[0032] According to the conditions and steps described in Example 1, only the production scale is changed to a 200,000-ton / year isobutane dehydrogenation isobutene plant, and the composition of the reaction gas is also changed. The composition of the reaction gas is as follows:

[0033] component name

[0034] The process flow combining heat pump rectification separation and molecular sieve adsorption separation of the present invention is adopted to prepare high-purity isobutene. The operating conditions of the light hydrocarbon removal tower (1) are: the operating gauge pressure is 0.64MPa, and the operating temperature is 51-60°C. The operating conditions of the heavy hydrocarbon removal tower (2) are: the operating gauge pressure is 0.58MPa, and the operating temperature is 51-64°C. The operating conditions of the adsorption tower are: operating gauge pressure 0.02MPa, operating temperature 111°C. The molecular sieve adsorbent is: calcium-containing modified 5A ...

Embodiment 3

[0036] According to the conditions and steps described in Example 1 and the composition of the reaction gas, the production scale is still 100,000 tons / year isobutane dehydrogenation isobutene plant as an example, but the process operating conditions are changed, and the heat pump rectification separation and The technological process of molecular sieve adsorption and separation is used to prepare high-purity isobutene. The operating conditions of the light hydrocarbon removal tower (1) are: the operating gauge pressure is 0.52MPa, and the operating temperature is 46-56°C. The operating conditions of the heavy hydrocarbon removal tower (2) are: the operating gauge pressure is 0.48MPa, and the operating temperature is 48-60°C. The operating conditions of the adsorption tower are: operating gauge pressure 0.01MPa, operating temperature 105°C. The molecular sieve adsorbent is: calcium-containing modified 5A molecular sieve. The isobutane effluent at the top of the light hydroca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com