Fuel gas reforming liquid and fuel gas reforming and preparation method

A technology for reforming liquid and gas, applied in the direction of fuel, gas fuel, petroleum industry, etc., can solve the problems of low safety and high cost, and achieve the effects of good safety, easy storage, energy saving and economical saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

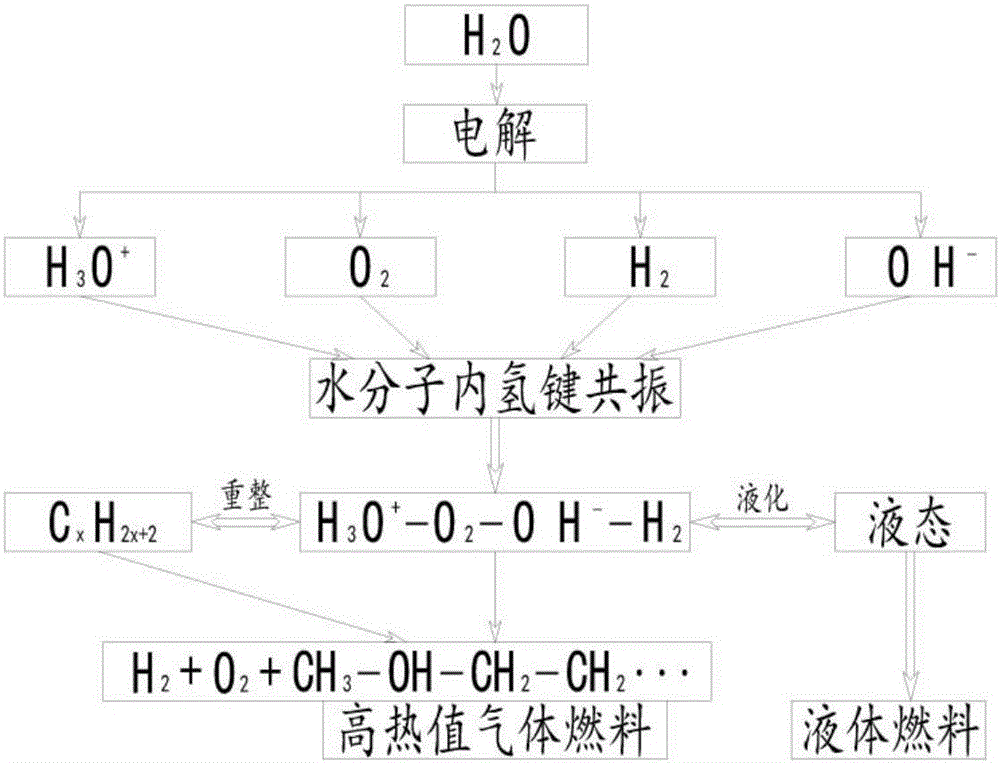

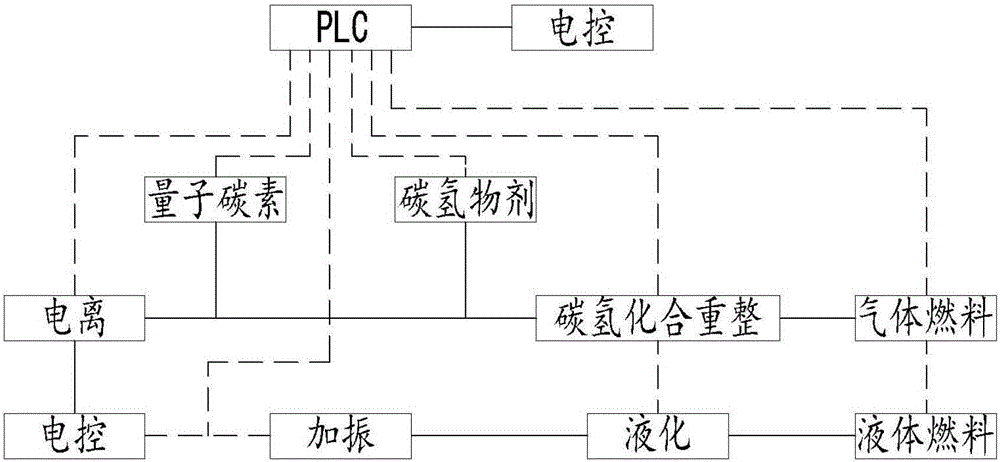

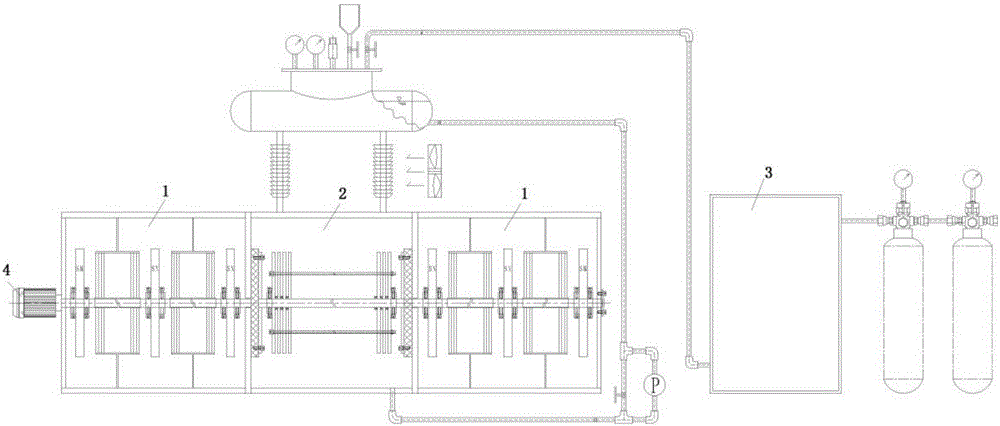

Method used

Image

Examples

Embodiment 1

[0092] Water ionization: Ionized H 3 O + +HO - The mixture of proton hydrate and hydroxide ion is combined with alkanes for reforming.

[0093] For the electrolyte 2-12, the KOH concentration is 5%-30%, and 15% is selected. The reforming liquid 2-21 is selected to include a mixture of C1-C5 alcohol alkane.

[0094] The molecular gas components of the hydrocarbon structure prepared according to the method in Example 1 are detected and analyzed, and the chromatographic analysis results are as follows Figure 16 As shown; chromatographic analysis records are as Figure 17 Shown. The detection and analysis results show that the gas is composed of a variety of hydrocarbon structures, with a calorific value> 12000Kcal / m 3 .

Embodiment 2

[0096] Water ionization: Ionized H 3 O + +HO - The mixture of proton hydrate and hydroxide ion is combined with alkanes for reforming.

[0097] The concentration of KOH for electrolyte 2-12 is 5%-30%, and 20% is selected. The reformed liquid 2-21 is a hydrocarbon, and a mixture of C3-C8 alkane is selected.

[0098] The molecular gas composition of the hydrocarbon structure before and after reforming is shown in the table below. It can be seen from the table that the heating value of the multi-component hydrocarbon structure is more than 30000Kcal / m 3 .

[0099] Table 2-Analysis of molecular gas composition of hydrocarbon structure before and after reforming

[0100] ingredient

Embodiment 3

[0102] Water ionization: Ionized H 3 O + +HO - The mixture of proton hydrate and hydroxide ion is combined with alkanes for reforming.

[0103] For the electrolyte 2-12, the KOH concentration is 5%-30%, and 30% is selected. The reformed liquid 2-21 is a hydrocarbon, and a C5-C12 alcohol alkane mixture is selected. Multi-component hydrocarbon structure calorific value> 50000Kcal / m 3 .

[0104] The examples show that the safe high-calorific value gas of the present invention is a clean energy source and has excellent energy-saving and emission-reduction effects compared with any existing conventional fuels. It can be seen from the combustion performance that compared with conventional fuels, energy saving and economy can be saved by more than 50%; NOX, SOX, CO2 and other harmful gas emissions can be effectively controlled, and combustion emissions can be reduced by more than 60%. The present invention is not limited to the above examples, and can be applied to all applications in ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Calorific value | aaaaa | aaaaa |

| Calorific value | aaaaa | aaaaa |

| Calorific value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com