A Rapier Loom with Improved Structure

A technology for rapier looms and improved structures, which is applied in looms, textiles, textiles, and papermaking, etc. It can solve the problems of affecting shearing action, shearing motion failure, and increasing follow-up processes, so as to change yarn tension and tension The effect of smooth change and improvement of weaving quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

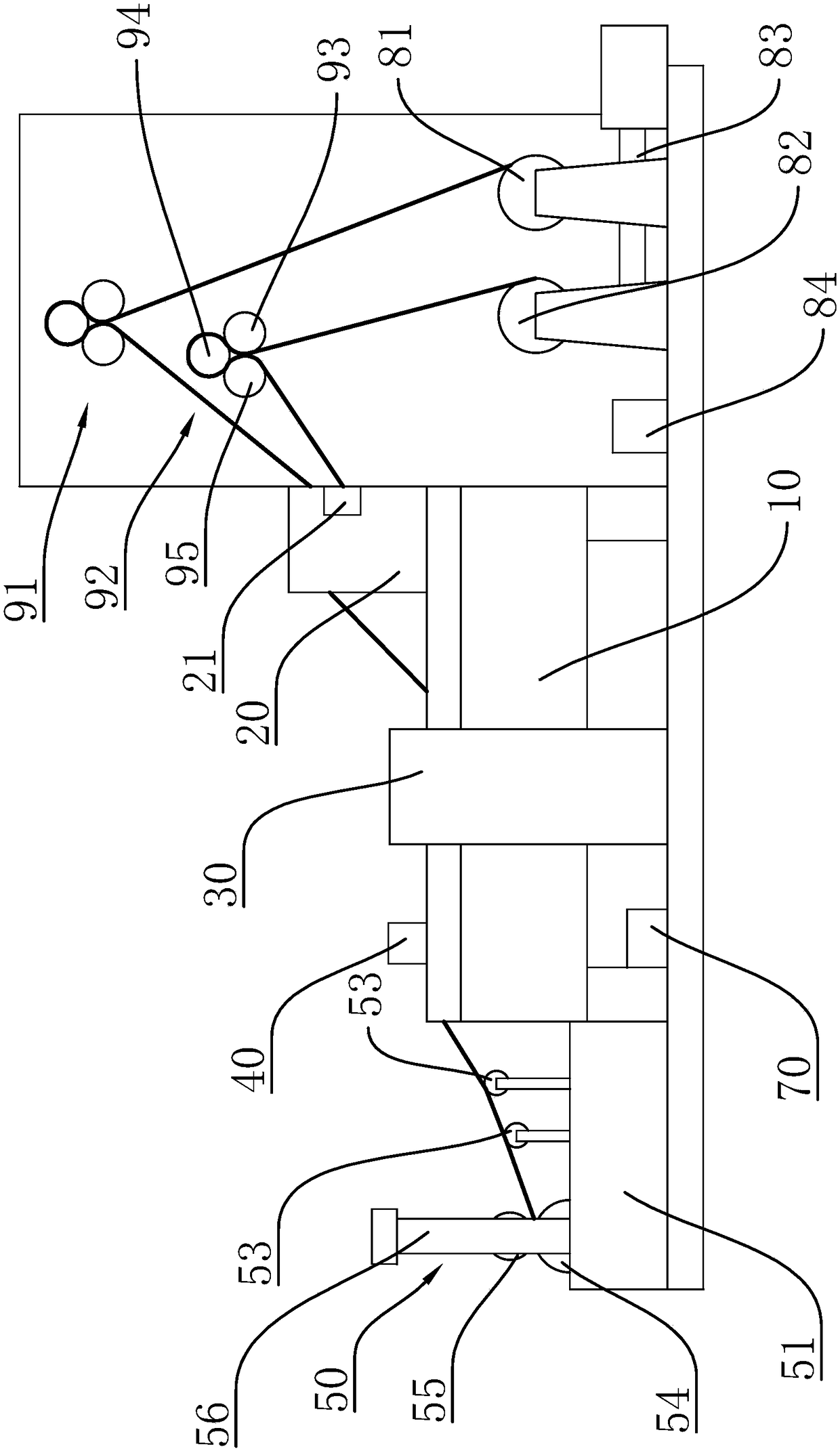

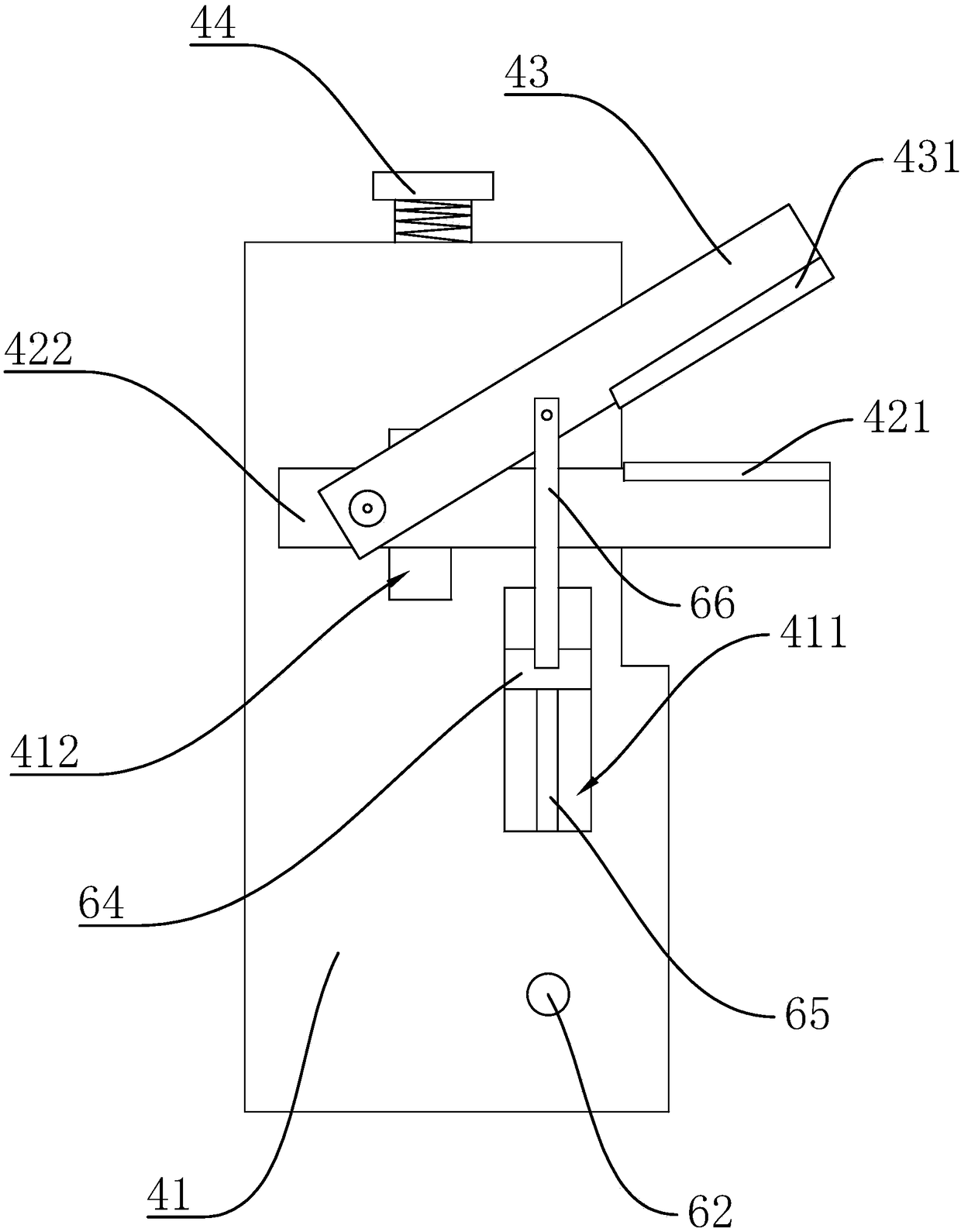

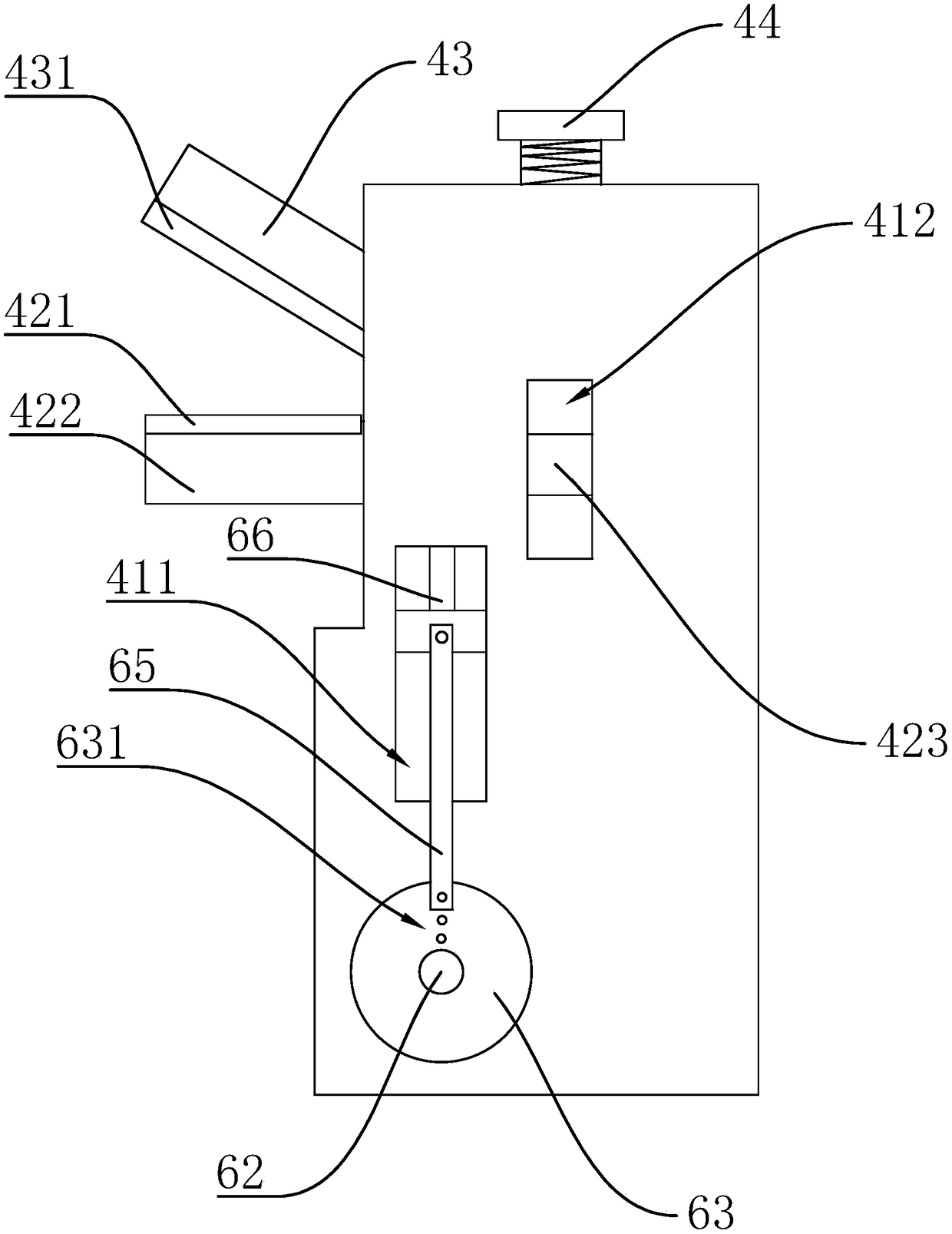

[0034] Such as Figure 1 to Figure 5 As shown, the present invention provides a kind of rapier loom of improved structure, comprises workbench 10, warp let-off mechanism 20, weft feed mechanism 30, waste edge cutting mechanism 40 and winding mechanism 50, the front of warp let-off mechanism 20 is provided with There are a first warp beam 81 and a second warp beam 82 wound with warp yarns, and the first warp beam 81, the second warp beam 82, the let-off mechanism 20, the workbench 10, and the winding mechanism 50 are arranged sequentially from front to back according to the process direction , The weft feeding mechanism 30 is arranged on one side of the workbench 10, and the waste edge cutting mechanism 40 is installed abov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com