Method for improving utilization rate of P-RC-APMP (pre-treatment alkaline hydrogen peroxide mechanical pulp) process pulping and bleaching filter liquid

A bleaching solution and pulping technology, applied in pulp bleaching, pulp beating/refining method, cellulose pulp post-treatment, etc., can solve the problems of increased chemical consumption, increased burden of sewage treatment, waste, etc., and achieves improved effect. , the effect of reducing the burden and improving the utilization efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

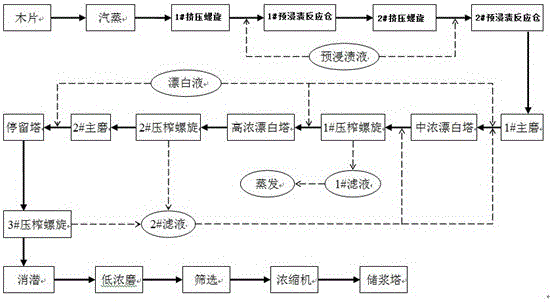

[0021] A method for improving the utilization efficiency of bleaching liquor in P-RC APMP pulping. P-RC APMP pulping includes the following steps: wood chips are steamed in sequence, 1# extrusion screw, 1# pre-impregnation reaction chamber, 2# extrusion Press screw and 2# pre-impregnation reaction chamber to get slurry; slurry passes through 1# main mill, medium-concentration bleaching tower, 1# pressing screw, high-consistency bleaching tower, 2# pressing screw, 2# main mill, retention tower, 3# pressing screw, and then go through potential elimination, low-consistency grinding, screening and thickening machine, and finally reach the pulp storage tower to complete pulping; the filtrate extracted by 2# pressing screw and 3# pressing screw is combined and sent to the medium-consistency bleaching tower. 55% of the final filtrate is sent to the medium-concentration bleaching tower and mixed with fresh bleaching liquid to continue bleaching. The remaining 45% of the combined filtra...

Embodiment 2

[0023]A method for improving the utilization efficiency of bleaching liquor in P-RC APMP pulping. P-RC APMP pulping includes the following steps: wood chips are steamed in sequence, 1# extrusion screw, 1# pre-impregnation reaction chamber, 2# extrusion Press screw and 2# pre-impregnation reaction chamber to get slurry; slurry passes through 1# main mill, medium-concentration bleaching tower, 1# pressing screw, high-consistency bleaching tower, 2# pressing screw, 2# main mill, retention tower, 3# pressing screw, and then go through potential elimination, low-consistency grinding, screening and thickening machine, and finally reach the pulp storage tower to complete pulping; the filtrate extracted by 2# pressing screw and 3# pressing screw is combined and sent to the medium-consistency bleaching tower. 65% of the final filtrate is sent to the medium-concentration bleaching tower and mixed with fresh bleaching liquid to continue bleaching. The remaining 35% of the combined filtrat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com