Device and method for batch deacidification of paper documents

A technology for deacidification and documentation, applied in the field of machinery, can solve the problems of paper strength reduction, different hand feeling, restrictions, State Archives Bureau, Shanghai Library, etc., and achieve the effect of prolonging life and safe and reliable operation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

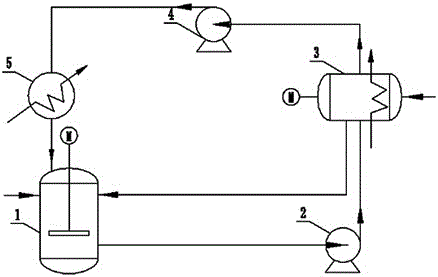

[0023] Embodiment of the present invention is described below in conjunction with accompanying drawing, embodiment does not constitute limitation of the present invention:

[0024] A device suitable for batch deacidification of paper documents is characterized in that it includes a deacidification liquid storage tank, the deacidification liquid storage tank is connected to a feed pump through a pipeline, and the feed pump is connected to a deacidification reactor through a pipeline. The deacidification reactor includes a rotating drum inside, and the rotating drum includes an opening on one side; the deacidification reactor is connected to a vacuum pump through a pipeline, the vacuum pump is connected to a cooling recovery device through a pipeline, and the cooling recovery device is connected to a deacidification liquid storage tank. The substantial technical effect and the realization process of the technical solution here are as follows: the deacidification solution can soak...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com