Manufacturing method of scripture piece of prayer wheel

A production method and technology of prayer wheels, which are applied in the direction of special paper, non-fiber pulp addition, papermaking, etc., can solve the problems of wasting microfilm space, etc., and achieve the effects of avoiding thick ink marks, strong three-dimensional effect, and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

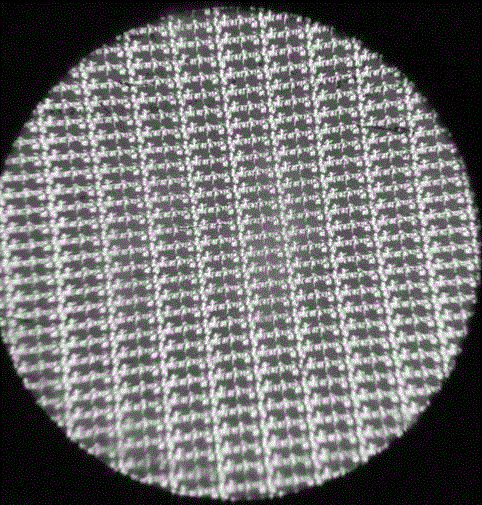

[0067] see figure 2 , this is the display view of the scriptures of Guru Rinpoche Mantra formed on microfilm under a 100-fold microscope using the production method of the scripture sheet of the prayer wheel of the present invention. all over. The printing paper pulp is bleached kraft softwood pulp with a beating degree of 41°SR, Italian poplar alkaline hydrogen peroxide thermomechanical pulp with a beating degree of 55°SR, and hardwood bleached chemical thermal grinding pulp with a beating degree of 36°SR. Mechanical pulp; pulp weight ratio is bleached kraft softwood pulp: hardwood bleached chemical thermomechanical pulp: Italian poplar alkaline hydrogen peroxide thermomechanical pulp is 28:32:40;

[0068] The amount of auxiliary materials for the printing paper to the absolute dry pulp is calculated by weight ratio: 0.15% of the amount of alkyl ketene dimer, 0.4% of the amount of polyamide polyamine epichlorohydrin resin, 0.03% of the amount of polyacrylamide, polyethylene...

Embodiment 2

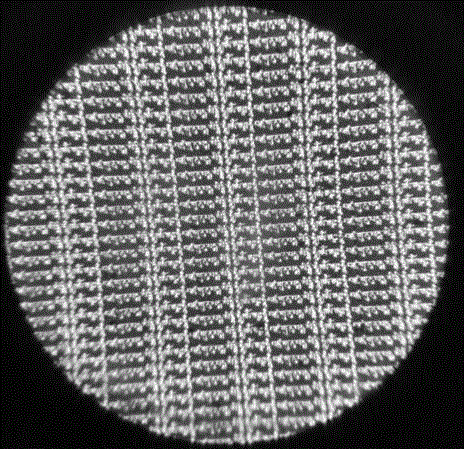

[0075] see image 3 , this is the display view of the Avalokitesvara mantra scriptures formed on the microfilm under a 100-fold microscope in the method for making the scripture sheet of the prayer wheel of the present invention, and the Avalokitesvara mantra is about 2.7 million times per meter of film 22 frames. Wherein the size of the printing paper is bleached kraft softwood pulp with a beating degree of 43°SR, Italian poplar alkaline hydrogen peroxide thermomechanical pulp with a beating degree of 52°SR, and hardwood bleached chemical pulp with a beating degree of 38°SR. Thermomechanical pulp; pulp weight ratio is bleached kraft softwood pulp: hardwood bleached chemical thermomechanical pulp: Italian poplar alkaline hydrogen peroxide thermomechanical pulp is 25:34:35;

[0076]The amount of auxiliary materials for the printing paper to the absolute dry pulp is calculated by weight ratio: 0.2% of the amount of alkyl ketene dimer, 0.3% of the amount of polyamide polyamine ep...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com