Geopolymer pervious concrete and preparation method thereof

A technology of permeable concrete and geopolymer, applied in ceramic products, cement production, other household appliances, etc., can solve the problems of easy cracking, poor water permeability, threshing and slag removal of permeable concrete, and achieve the improvement of strength and permeability coefficient, and easy aging , the effect of poor weather resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

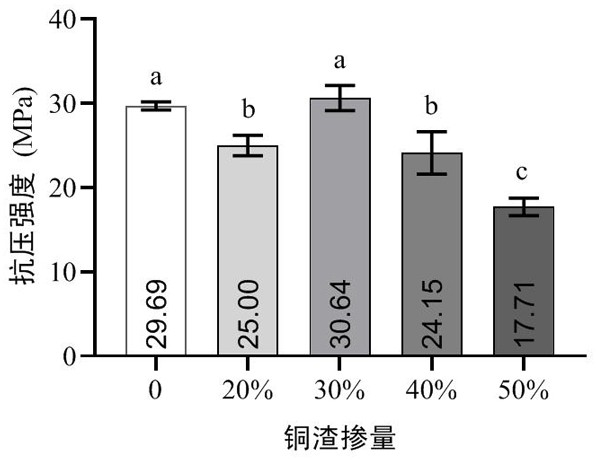

[0032] The preparation process of the geopolymer gelling material is as follows: according to the water-binder ratio of 0.26 (water-binder ratio: the ratio of the sum of the water content in the added water and the water glass to the mass of the gelling material, wherein the water content of the water glass is 56.26wt%), The excitation-solid ratio is 1 and the modulus of water glass is 1.4, and the cementitious material is equipped with 50.00g copper slag (accounting for 30% of the mass of the solid powder material), 116.67g of metakaolin (accounting for 70% of the solid powder material) , 166.67g of activator (150.45g of water glass and 16.22g of NaOH) and 5g of water were poured into a planetary cement mortar mixer, and stirred at room temperature (140r / min) for 150s to obtain a cementitious material.

[0033] When the amount of copper slag is 0, 20%, 40%, and 50%, the amount of copper slag is 0g, 33.33g, 66.67g, 83.34g, and the amount of metakaolin in the powder material is ...

Embodiment 2

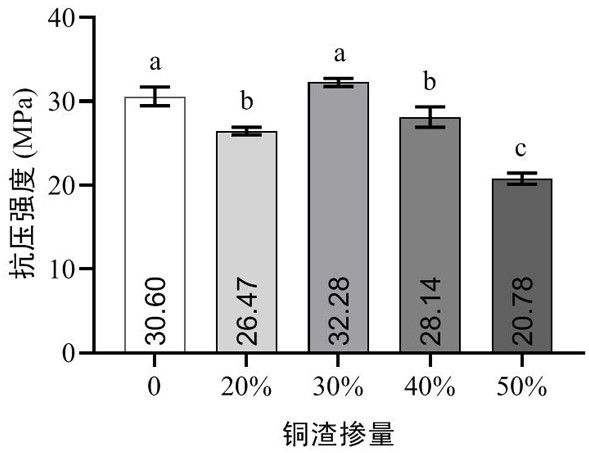

[0037] The preparation process of geopolymer permeable concrete: according to the water-binder ratio of 0.26 (the ratio of the sum of the water content in the added water and water glass to the mass of the colloidal material, in which the water content of water glass is 56.26wt%), the shock-solid ratio is 1, The water glass modulus is 1.4, and the cementitious material is equipped; according to the bone-to-cement ratio of 6:1, 190.00g of copper slag (accounting for 30% of the mass of the powder material), 443.33g of metakaolin (accounting for the mass of the powder material) 70% of ), 3086g of coarse aggregate and 4629g of fine aggregate were poured into the self-consolidating concrete mixer, and stirred for 90s at room temperature (rotation speed 45r / min), in which the aggregate particle size was 4.75mm~9.50mm and 2.36mm~4.75 The mass ratio of mm is 2:3; finally, pour 633.33g of activator (571.70g of water glass and 61.63g of NaOH) and 19.0g of added water into the well-stirre...

Embodiment 3

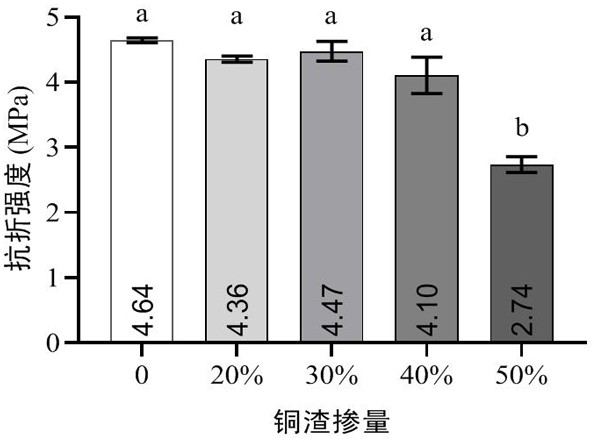

[0041] The preparation process of the geopolymer gelling material is as follows: according to the water-binder ratio of 0.26 (the ratio of the sum of the water content in the added water and the water glass to the mass of the colloidal material, wherein the water content of the water glass is 56.26wt%), the shock-solid ratio is 1 The modulus of water glass is 1.4, and the cementitious material is equipped; 18.50g copper slag (accounting for 30% of the mass of the powder material), 43.17g metakaolin (accounting for 70% of the mass of the powder material), and 61.67g of the activator (55.67g water glass and 6.00g NaOH), 0.75g water were poured into a planetary cement mortar mixer, and stirred at room temperature for 150s (speed 140r / min) to obtain a cementitious material. When the amount of copper slag is 0, 20%, 40%, and 50%, the amount of copper slag is: 0g, 12.33g, 24.67g, and 30.84g; the amount of metakaolin in the powder material is: 61.67g, 49.33 g, 37.00g, 30.83g. When t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com