Building roof waterproof layer

A waterproof layer and construction technology, applied in the direction of construction, building structure, roof covering, etc., can solve the problems of short service life and high price, achieve the effect of delaying corrosion rate, reducing energy consumption of temperature control, and improving safe service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

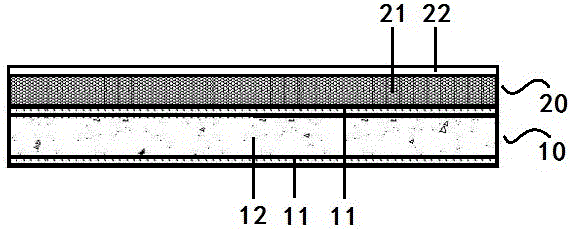

Image

Examples

Embodiment 1

[0021] A transparent flexible layer with a thickness of 50 μm was formed on the upper surface of the No. 45 steel substrate by roller coating, and a transparent protective film layer of polytetrafluoroethylene with a thickness of 10 μm was arranged on the transparent flexible layer. The transparent flexible layer consists of 8.0wt% zinc powder, 10.0wt% zinc oxide, 5.0wt% nano zinc aluminum hydrotalcite, 2.0wt% aminoalkyltrimethoxysilane, 2.0wt% N-(2 -Mercapto-1-carboxyethyl) acrylamide, and the composition formed by the remainder acrylic resin.

Embodiment 2

[0023] A transparent flexible layer with a thickness of 50 μm was formed on the upper surface of the No. 45 steel substrate by roller coating, and a transparent protective film layer of polytetrafluoroethylene with a thickness of 10 μm was arranged on the transparent flexible layer. The transparent flexible layer is composed of 12.0wt% zinc powder, 8.0wt% zinc oxide, 4.0wt% nano zinc aluminum hydrotalcite, 2.0wt% aminoalkyltrimethoxysilane, 2.5wt% acrylic acid 2-mercapto -1-carboxyethyl ester, and the balance of acrylic resin composition.

Embodiment 3

[0025] A transparent flexible layer with a thickness of 50 μm was formed on the upper surface of the No. 45 steel substrate by roller coating, and a transparent protective film layer of polytetrafluoroethylene with a thickness of 10 μm was arranged on the transparent flexible layer. The transparent flexible layer is made of 10.0wt% aluminum, 10.0wt% zinc oxide, 5.0wt% nano zinc aluminum hydrotalcite, 2.0wt% aminoalkyltrimethoxysilane, 2.5wt% N-(2- Mercapto-1-carboxyethyl) acrylamide, and the remainder of the composition formed by acrylic resin.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com