Intelligent pulse combustion system

A pulse combustion and intelligent technology, applied in the direction of burner, combustion method, combustion type, etc., can solve problems such as poor control effect, achieve convenient operation and maintenance, reduce system cost, and increase reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The principle and specific implementation of the present invention will be further described below in conjunction with the accompanying drawings.

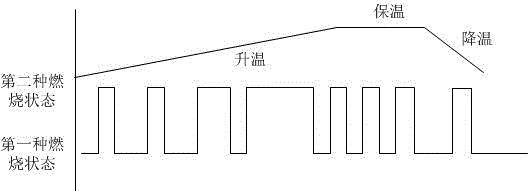

[0023] Pulse combustion adopts an intermittent combustion method to achieve temperature control in the furnace. The fuel flow rate can be preset through pressure adjustment. Once the burner is working, according to the requirements of the heating process curve, when the temperature needs to be raised, set the target temperature. The second combustion state The longer the time, the shorter the intermittent time; when it is close to the target temperature, the time of the second combustion state will be reduced, the time of the first combustion state will be longer, and it will enter the heat preservation state. figure 1 .

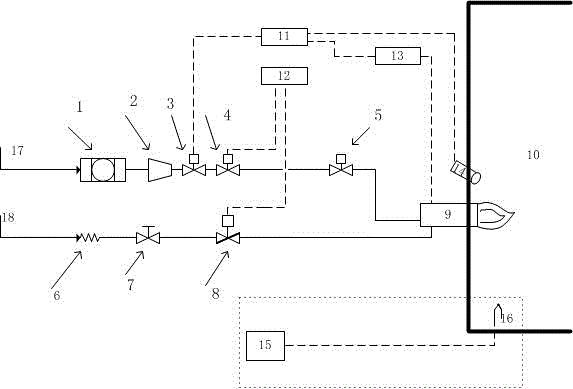

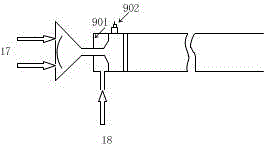

[0024] Intelligent pulse combustion system, including gas pipeline 17, combustion-supporting air pipeline 18, burner 9, temperature sensor 16 and control system, gas pipeline 17 and combustion-supporting a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com