A method for controlling the oxygen amount at the outlet of a w-type flame boiler economizer

A control method and outlet oxygen technology, applied in the direction of combustion method, combustion control, fuel supply adjustment, etc., can solve problems such as deviation of oxygen amount at the outlet of economizer, high concentration of nitrogen oxide emission, uneven combustion of furnace, etc. Achieve the effects of improving furnace combustion, increasing boiler efficiency, and reducing carbon content in fly ash

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] The coal mills specifically put into operation in this embodiment are B and D coal mills.

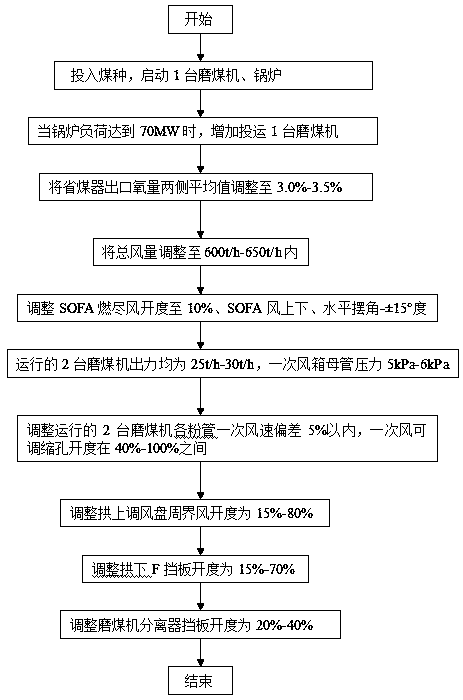

[0047] Such as figure 1 As shown, the specific steps of the oxygen control method at the outlet of the W-type flame boiler economizer of the present invention are as follows:

[0048] (1) Input coal type, start a coal mill and boiler;

[0049] (2) When the working load of the boiler reaches 70MW, an additional coal mill will be put into operation;

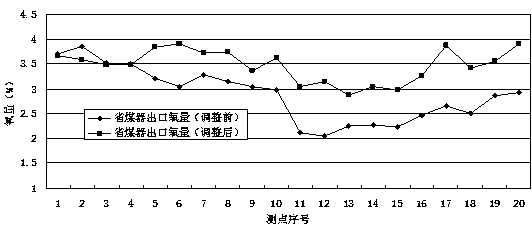

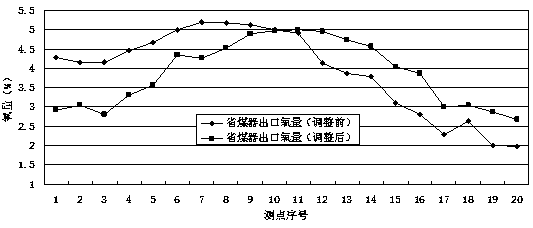

[0050](3) Adjust the average value of oxygen on both sides of the economizer outlet to 2.5%-3.5%;

[0051] (4) Adjust the total air volume of the boiler operation to 600t / h-650t / h;

[0052] (5) Adjust the opening of the SOFA overburning air to 10%, and the SOFA air up and down and horizontal swing angles are both ± 15°;

[0053] (6) Adjust the output of the two coal mills in operation to 25t / h-30t / h, and adjust the pressure of the main pipe of the primary bellows to 5kPa-6kPa;

[0054] (7) The method to adjust the deviation of t...

Embodiment 2

[0060] The specific coal mills put into operation in this embodiment are B and C coal mills, and A and D coal mills are reserved for standby.

[0061] The specific steps of the oxygen control method at the outlet of the W-type flame boiler economizer of the present invention are as follows:

[0062] (1)-(6) are the same as embodiment 1;

[0063] (7) The method to adjust the deviation of the primary wind speed of each powder pipe of the two coal mills in operation within 5% is: adjust the primary air of each powder pipe of B coal mill B1-B6 to adjust the shrinkage hole opening to 50%, 60% respectively %, 70%, 45%, 90% and 100%, adjust the opening degree of the primary air of each powder pipe of C pulverizer C1-C6 to be 55%, 65%, 90%, 75%, 60% and 80%;

[0064] (8) The specific method for adjusting the perimeter air opening of the air regulating disk on the arch to 15%-80% is as follows: Adjust the surrounding air opening of the air regulating disk of the burner corresponding ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com