Character guided wave based butt-weld defect detection system and detection method thereof

A technology of characteristic guided wave and defect detection, which is applied in the generation of ultrasonic/sonic wave/infrasonic wave, measuring device, and processing detection response signal, etc., which can solve the problems of low detection efficiency, improve detection efficiency, be convenient to carry, and realize online Detection effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, but the protection scope of the present invention is not limited thereto.

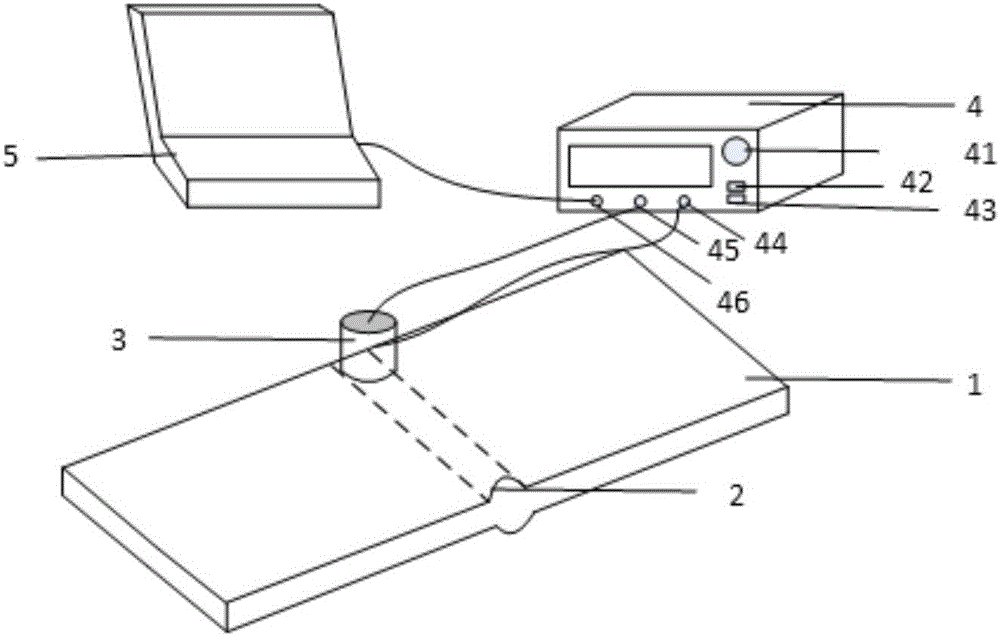

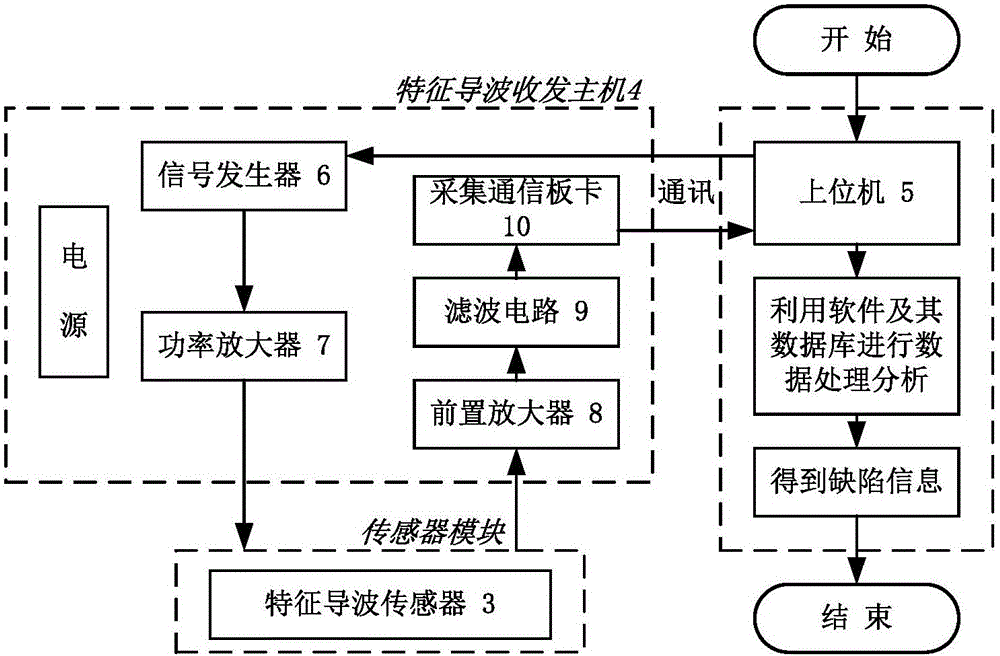

[0036] Such as figure 1 , 2 As shown, a butt weld defect detection system based on characteristic guided waves is composed of a characteristic guided wave transceiver host 4, a characteristic guided wave sensor 3 and a host computer 5;

[0037] The characteristic guided wave sensor 3 is arranged parallel to the upper end surface of the inspected weld seam 2 of the plate 1 along the direction of the inspected weld seam 2; The wave sensor 3 is connected, and another communication serial port 46 of the characteristic guided wave transceiver host 4 is connected with the host computer 5, so as to realize the signal transmission in the weld defect detection process;

[0038] The characteristic guided wave transceiver host 4 is composed of a signal generator 6, a power amplifi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Sampling rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com