Radio-frequency horizontal double diffusion metal oxide semiconductor device and manufacturing method

A technology of oxide semiconductor and fabrication method, applied in semiconductor/solid-state device manufacturing, semiconductor devices, electrical components, etc., can solve problems such as large size, existing risks, and the sinking area cannot be well connected to the source area.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments. The following examples are used to illustrate the present invention, but should not be used to limit the scope of the present invention.

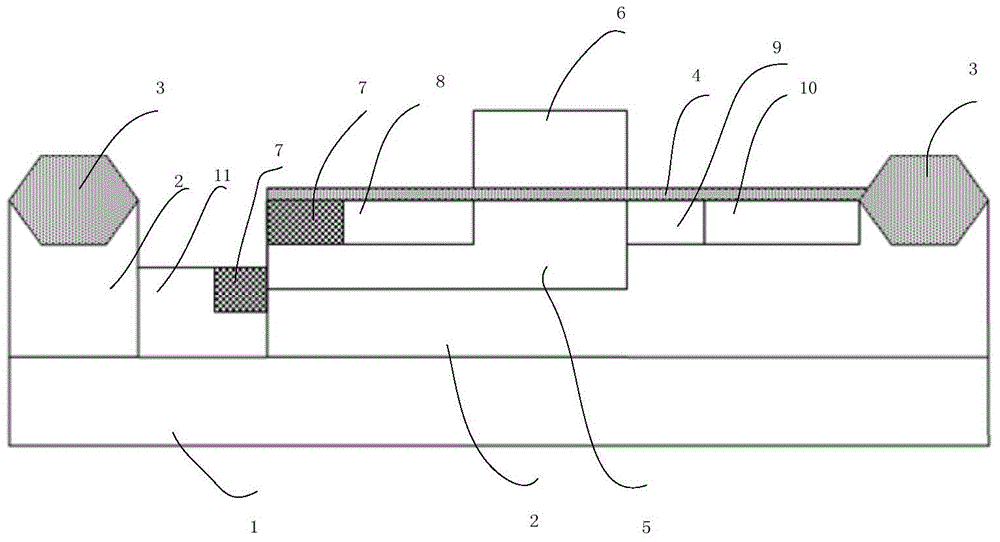

[0042] figure 1 It is a schematic diagram of the structure of a radio frequency horizontal double-diffused metal oxide semiconductor device in the prior art. It can be seen from the figure that the device includes a substrate 1, an epitaxial layer 2, a field oxide layer 3, a gate oxide layer 4, a body region 5, and a polysilicon 6. Implantation region 7 , source region 8 , drift region 9 , drain region 10 and sinker region 11 . The implantation region 7 connects the sinker region 11 to the source region 8, and the implantation region 7 and the source region 8 are short-circuited through the metal of the contact hole. After the channel under the polysilicon is formed, the current can flow from the drain regi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com