A kind of method for preparing ingan/algan MQW violet light LED

A technology of ultraviolet light and pressure, applied in the direction of electrical components, circuits, semiconductor devices, etc., can solve the problems of high preparation cost, limited application, poor performance of ultraviolet LED, etc., and achieve the effect of low preparation cost and wide adjustment range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

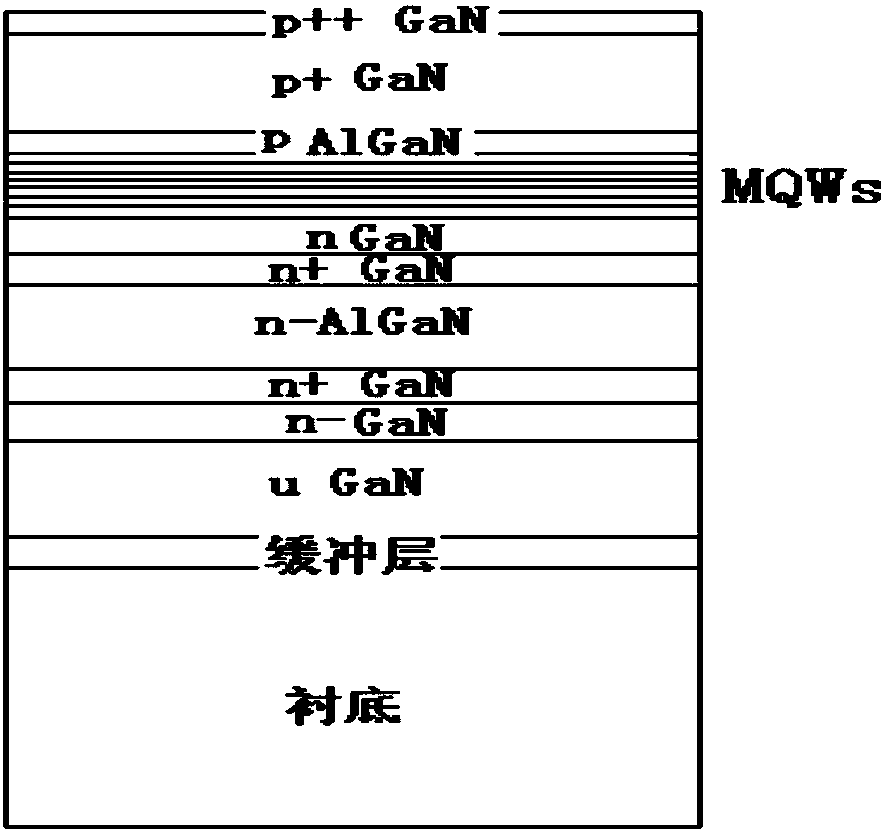

[0046] Such as figure 1 As shown in this embodiment, a method for preparing high-performance InGaN / AlGaN MQW violet LEDs is based on blue ammonia, trimethyl indium (TMIn) with a purity of 99.9999% and trimethylgallium (TMGa) with a purity of 99.9999% as N , In, Ga sources, respectively SiH 4 And Cp2Mg as n and p type dopants, including the following steps:

[0047] Step 1: Pass N at a temperature of 1070℃ and a pressure of 150torr 2 Bake for 20min, nitride sapphire substrate;

[0048] Step 2: Cool down the nitrided sapphire substrate in step 1 to 515°C and a pressure of 800 torr, and then grow a GaN buffer layer with a thickness of 15 nm on the substrate, and then heat up to 1030°C and a pressure of 400 torr to make the GaN buffer layer renew Crystallize and re-grow 1.8um u-GaN nucleation layer, raw materials are TMGa and NH 3 ;

[0049] Step 3: Raise the temperature to 1070℃, the pressure is 200torr, grow a low-Si-doped n-GaN layer with a thickness of 20nm, and then grow a high-Si-...

Embodiment 2

[0065] Such as figure 1 As shown in this embodiment, a method for preparing high-performance InGaN / AlGaN MQW violet LEDs is based on blue ammonia, trimethyl indium (TMIn) with a purity of 99.9999% and trimethylgallium (TMGa) with a purity of 99.99999% as N , In, Ga sources, respectively SiH 4 And Cp2Mg as n and p type dopants, including the following steps:

[0066] Step 1: Pass N at a temperature of 1080 ℃ and a pressure of 150 torr 2 Baking for 25min, nitride SiC substrate;

[0067] Step 2: Cool down the nitrided SiC substrate in step 1 to 525°C and a pressure of 800 torr, and then grow a 30nm thick GaN buffer layer on the substrate, and then heat up to 1040°C and a pressure of 400 torr to restore the GaN buffer layer Crystallize and re-grow 2.1um u-GaN nucleation layer, raw materials are TMGa and NH 3 ;

[0068] Step 3: Raise the temperature to 1080°C, the pressure is 200torr, grow a low-Si-doped n-GaN layer with a thickness of 60nm, and then grow a high-Si-doped n+GaN layer with...

Embodiment 3

[0084] Such as figure 1 As shown in this embodiment, a method for preparing high-performance InGaN / AlGaN MQW violet LEDs is based on blue ammonia, trimethyl indium (TMIn) with a purity of 99.9999% and trimethylgallium (TMGa) with a purity of 99.9999% as N , In, Ga sources, respectively SiH 4 And Cp2Mg as n and p type dopants, including the following steps:

[0085] Step 1: Pass N at a temperature of 1090℃ and a pressure of 150torr 2 Bake for 30min, nitride Si substrate;

[0086] Step 2: Cool down the Si substrate after step 1 to 535°C and a pressure of 800 torr, then grow a GaN buffer layer with a thickness of 50nm on the substrate, and then heat up to 1050°C and a pressure of 400 torr to recrystallize the GaN buffer layer , And then grow a 2.5um u-GaN nucleation layer, the raw materials are TMGa and NH 3 ;

[0087] Step 3: Raise the temperature to 1090℃, the pressure is 200torr, grow a low-Si-doped n-GaN layer with a thickness of 100nm, and then grow a high-Si-doped n+GaN layer wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com