Processing method and device based on high-pressure water jet cavitation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

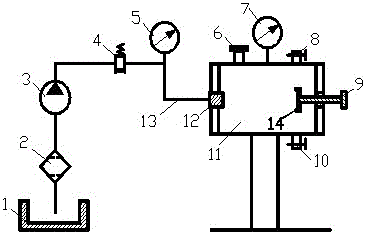

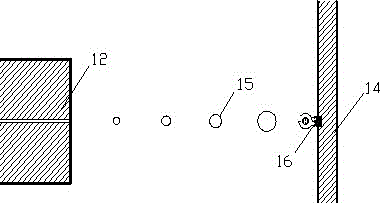

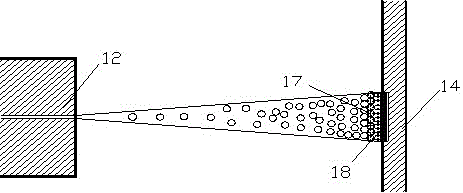

[0030] Embodiment 1: The material of the workpiece 14 used in this embodiment is ordinary steel with a hardness of HB=200. The thickness H=5mm and the diameter D based on the high-pressure water jet cavitation effect are described in detail in conjunction with the accompanying drawings. 1 =10mm through hole processing, which includes the following steps:

[0031] (1) Start the high-pressure pump set and run it for 10 minutes without load, and all indicators are normal;

[0032] (2) Control the pressure regulating valve, and wait for the pressure gauge 5 to rise slowly to 150MPa for 30 minutes, indicating that the high-pressure pump unit is operating normally, the system has no obvious leakage, the pressure is stable, and meets the implementation requirements;

[0033] (3) Fill the high-pressure vessel 11 with water and the height d from the water surface to the upper edge of the cavitation nozzle 12 1 =180mm, and pressurized so that the pressure p in the high pressure vessel ...

Embodiment 2

[0041] Embodiment 2: The material of the workpiece 14 used in this embodiment is ordinary steel with a hardness of HB=200. The thickness H=5 mm and the diameter D based on the high-pressure water jet cavitation effect are described in detail in conjunction with the accompanying drawings. 1 =10mm through hole processing, which includes the following steps:

[0042] (1) Start the high-pressure pump set and run it for 10 minutes without load, and all indicators are normal;

[0043] (2) Control the pressure regulating valve, and wait for the pressure gauge 5 to rise slowly to 150MPa for 30 minutes, indicating that the high-pressure pump unit is operating normally, the system has no obvious leakage, the pressure is stable, and meets the implementation requirements;

[0044] (3) Fill the high-pressure vessel 11 with water and the height d from the water surface to the upper edge of the cavitation nozzle 12 1 =180mm, and pressurized so that the pressure p in the high pressure vessel...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Outlet diameter | aaaaa | aaaaa |

| Hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com