Preparation method of sucrose-based hierarchical pore active carbon

A technology of graded pores and activated carbon, which is applied in the field of preparation of sucrose-based graded pores activated carbon, which can solve the problems of low preparation efficiency, low mesopority, long pore expansion treatment time, etc., and achieve the effect of broadening the application range and large specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

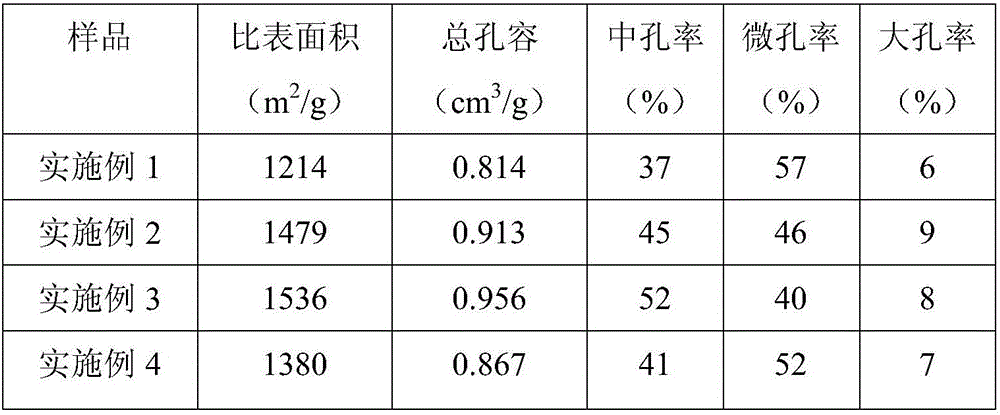

Embodiment 1

[0020] Step (1): Dissolve sucrose and nickel nitrate in water, wherein the mass ratio of sucrose and nickel nitrate is 40:1; stir at 80°C for 30 minutes, and stir to obtain the sucrose-nickel nitrate mixture;

[0021] Step (2): Put the sucrose-nickel nitrate mixture obtained in step (1) in a high-temperature furnace, and carry out high-temperature carbonization under the protection of an inert atmosphere, wherein the carbonization temperature is 600° C., and the carbonization time is 1 hour; material 1 is obtained;

[0022] Step (3): Add 3M hydrochloric acid to the material 1 obtained in step (2), stir at room temperature for 40 minutes, then reflux and stir at 50°C for 15 minutes; pickle, then wash with water until neutral, and dry; Get material two;

[0023] Step (4): Add KOH solution to the material 2 obtained in step (3) and mix evenly, wherein the mass ratio of material 2 to KOH is 1:1; then put it in an oven and dry it at 80°C for 30 minutes, and dry it Put the material...

Embodiment 2

[0026] Step (1): Dissolve sucrose and nickel nitrate in water, wherein the mass ratio of sucrose to nickel nitrate is 43:1; stir at 85°C for 40 minutes, and stir to obtain the sucrose-nickel nitrate mixture;

[0027] Step (2): Put the sucrose-nickel nitrate mixture obtained in step (1) in a high-temperature furnace, and carry out high-temperature carbonization under the protection of an inert atmosphere, wherein the carbonization temperature is 700° C., and the carbonization time is 2 hours; material 1 is obtained;

[0028] Step (3): add hydrochloric acid with a concentration of 4M to the material 1 obtained in step (2), stir at room temperature for 30 minutes, then reflux and stir at 55° C. for 20 minutes; pickle, then wash with water until neutral, and dry; Get material two;

[0029] Step (4): Add KOH solution to the material 2 obtained in step (3) and mix evenly, wherein the mass ratio of material 2 to KOH is 1:2; then put it in an oven and dry it at 100°C for 30 minutes, a...

Embodiment 3

[0032] Step (1): Dissolve sucrose and nickel nitrate in water, wherein the mass ratio of sucrose to nickel nitrate is 45:1; stir at 85°C for 50 minutes, and stir to obtain the sucrose-nickel nitrate mixture;

[0033] Step (2): Put the sucrose-nickel nitrate mixture obtained in step (1) in a high-temperature furnace, and carry out high-temperature carbonization under the protection of an inert atmosphere, wherein the carbonization temperature is 750° C., and the carbonization time is 2 hours; material 1 is obtained;

[0034] Step (3): add hydrochloric acid with a concentration of 4M to the material 1 obtained in step (2), stir at room temperature for 30 minutes, then reflux and stir at 60° C. for 20 minutes; pickle, then wash with water until neutral, and dry; Get material two;

[0035] Step (4): Add KOH solution to the material 2 obtained in step (3) and mix evenly, wherein the mass ratio of material 2 to KOH is 1:3; put it in an oven and dry at 100°C for 30 minutes, and dry ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com