Activated carbon/lithium titanate composite electrode material, preparation method and supercapacitor

A composite electrode and lithium titanate technology, which is applied in the manufacture of battery electrodes, non-aqueous electrolyte batteries, electrolyte batteries, etc., can solve the problem of reducing the pore volume of activated carbon and the specific surface area of composite materials, and insufficient contact between lithium titanate and electrolyte , affect the power density of capacitors and other issues, and achieve the effects of large-scale production, low cost, and high mesoporosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

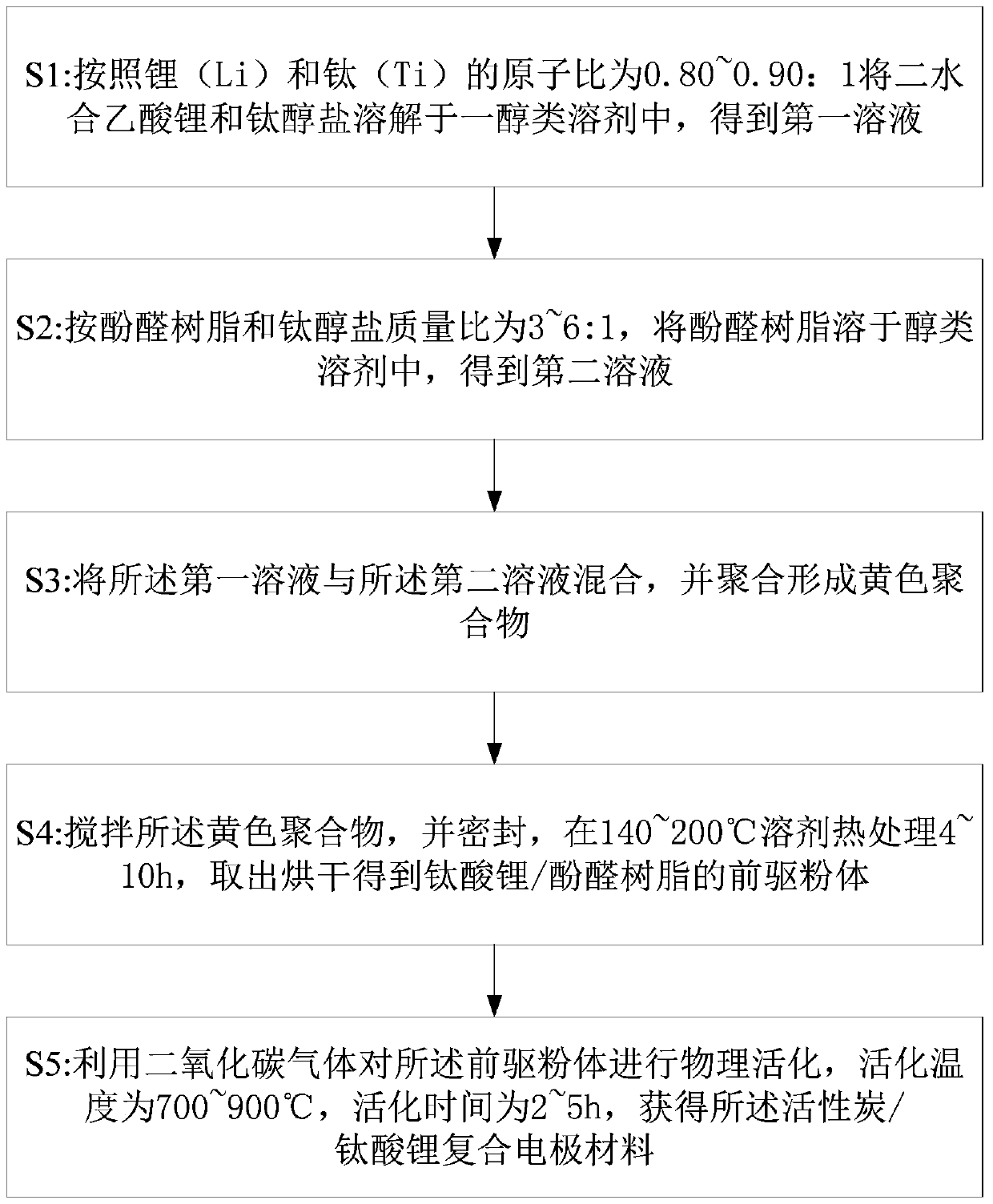

[0022] Please refer to figure 1 , a preparation method of activated carbon / lithium titanate composite electrode material, comprising the following steps:

[0023] S1: According to the atomic ratio of lithium (Li) and titanium (Ti) being 0.80~0.90:1, dissolving lithium acetate dihydrate and titanium alkoxide in an alcoholic solvent to obtain a first solution;

[0024] S2: according to phenolic resin and titanium alkoxide mass ratio is 3~6:1, phenolic resin is dissolved in the alcoholic solvent, obtains the second solution;

[0025] S3: mixing the first solution with the second solution, and polymerizing to form a yellow polymer;

[0026] S4: Stir the yellow polymer, seal it, heat it with a solvent at 140-200° C. for 4-10 hours, take it out and dry it to obtain the precursor powder of lithium titanate / phenolic resin;

[0027] S5: Physically activate the precursor powder with carbon dioxide gas, the activation temperature is 700-900° C., and the activation time is 2-5 hours, to...

Embodiment 1

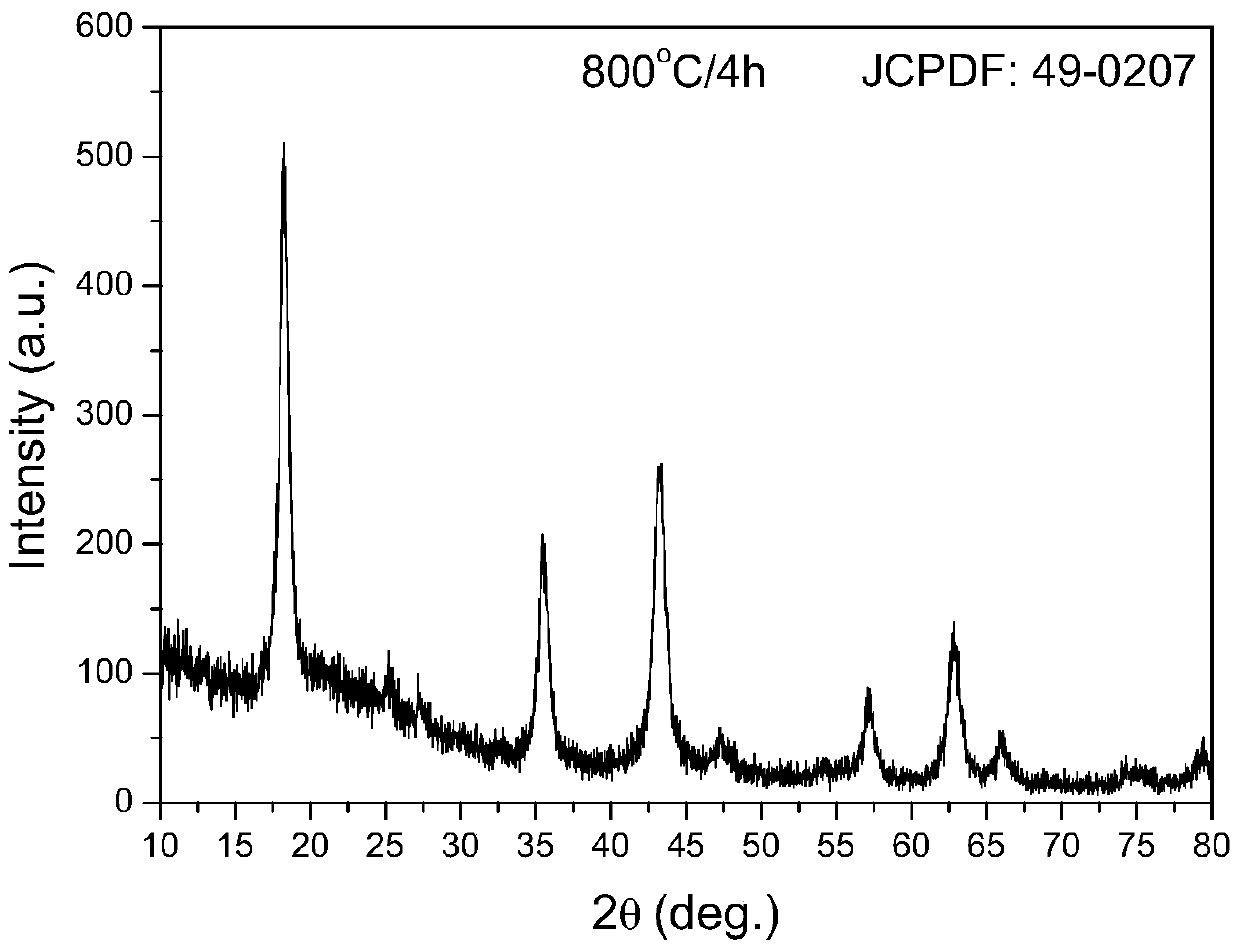

[0036] In a stirring state, add an appropriate amount of lithium acetate monohydrate and tetrabutyl titanate to 20 ml of ethanol at a ratio of Li atom to Ti atom of 0.85:1 to obtain the first solution; according to the mass ratio of phenolic resin and tetrabutyl titanate 5:1, an appropriate amount of phenolic resin was dissolved in 50ml ethanol to obtain the second solution; the first solution was added to the second solution to form a yellow polymer; the polymer product was stirred evenly, and then transferred into a stainless steel reaction kettle with a volume of 100ml , after sealing, solvent heat treatment at 160°C for 8h, take it out and dry it directly at 70°C to obtain the lithium titanate / phenolic resin precursor powder; the obtained lithium titanate / phenolic resin precursor powder was The physical activation is carried out in a carbon dioxide gas atmosphere, the activation temperature is 800 ° C, and the activation time is 4 h, that is, the activated carbon / lithium ti...

Embodiment 2

[0039] It is basically the same as Example 1, except that titanium isopropoxide is used instead of tetrabutyl titanate as the titanium source.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com