Cured carrier microorganism generating system

A technology for solidifying microorganisms and generating systems, applied in the ecological field of water resource regeneration and utilization, can solve the problems of short service cycle, no oxygen, slow growth rate, etc., and achieve the effects of accelerating production speed, improving purification efficiency and accelerating growth speed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

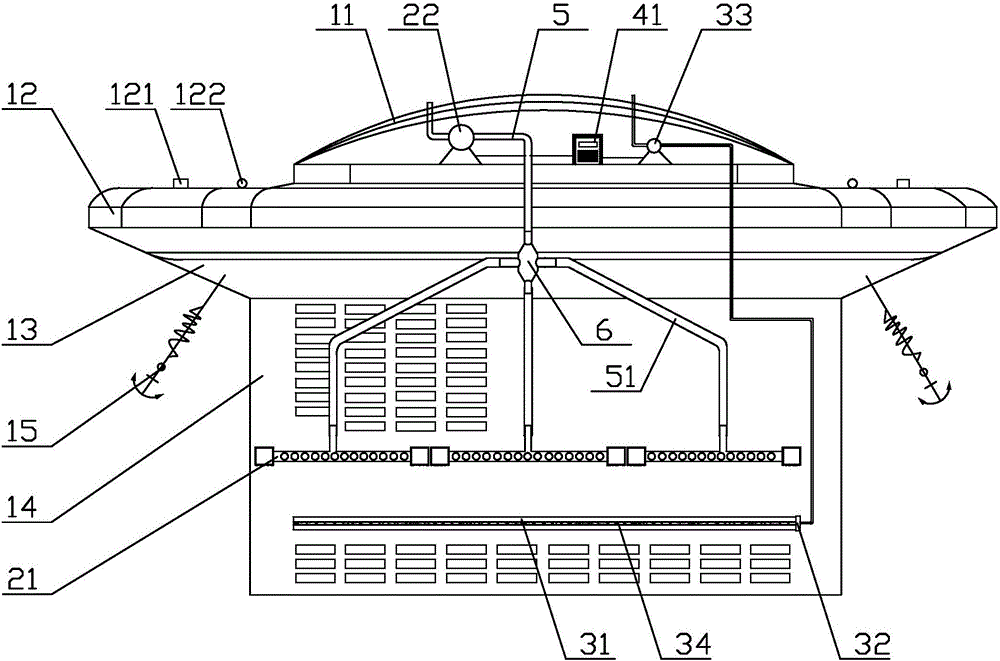

[0025] The present invention provides a solidified carrier microbial generation system, comprising a hull system, an aeration system, a solidified microbial carrier system and an electric control system; 15, the top cover 11 is arranged on the upper end of the pontoon 12, the four end corners of the pontoon are provided with suspension rings 121 and wire grooves 122, and brackets are arranged in the hull 14; the aeration system is composed of an aerator 21, a pipeline Composed of blower 22, the air inlet pipe of aerator 21 is connected with blower 22 by flange and pipeline; Described solidified microorganism carrier system is made up of solidified microorganism carrier pipe 31, flange 32, pipeline, air compressor 33, and all The described solidified microbial carrier tube is filled with functional microbial matrix, and the solidified microbial carrier 31 tube is connected with the air compressor 33 through flanges and pipelines; the aerator 21 is arranged on the upper end of th...

Embodiment 2

[0033] With other constructs being the same, such as figure 1 As shown, the aeration system is provided with three aerators, and the inlet pipe of each aerator is provided with a branch pipe 51, and the three branch pipes are connected to the main pipeline 5 through the four-way valve 6, and the main pipeline 5 is connected to the blower 22 connected.

[0034] Working principle: when working, place the invention in the water, use the anchor in the hull system to fix the position of the whole device, then turn on the blower, and the air enters the aerator under the action of the blower, when the sewage water quality in the river is relatively poor At the same time, the air compressor is turned on at the same time, and the air compressor quickly provides oxygen to the functional microorganisms with the weight of the solidified microbial carrier tube, which can accelerate the growth rate of microorganisms and improve the purification speed of the entire device.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com