Biurea preparation device and preparation method

A preparation device and technology of biurea, which is applied to the preparation device and field of production of biurea by condensation of hydrogen chloride gas, can solve the problems of cumbersome treatment process, many types of impurities, and high consumption of urea, so as to simplify the process and improve the conversion Efficiency, heat saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

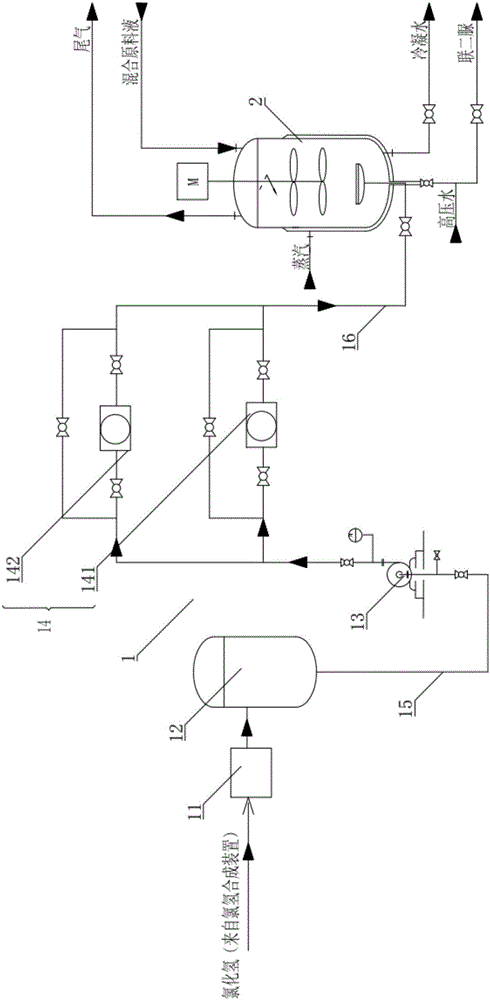

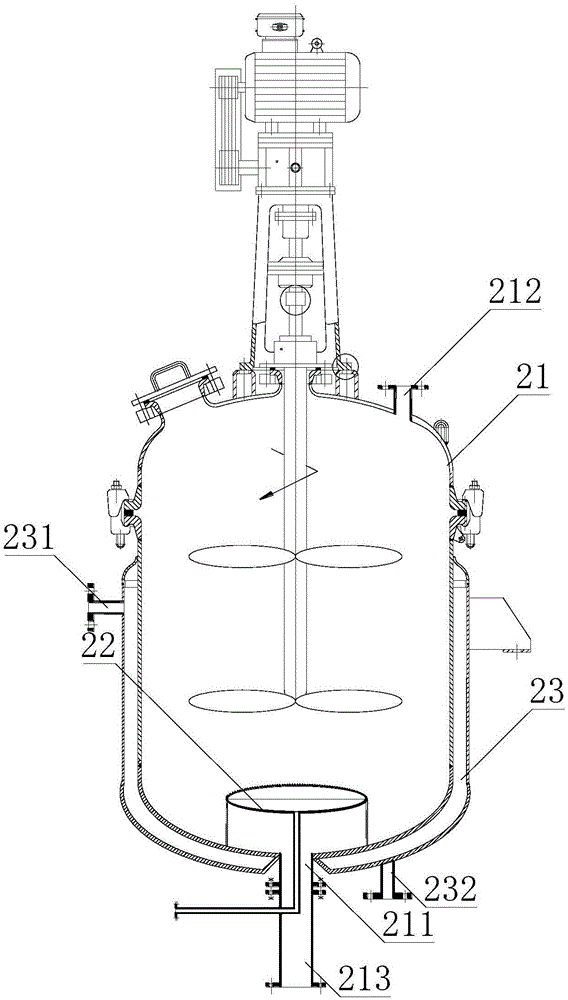

[0052] This embodiment provides a preparation method of biurea, comprising the following steps:

[0053] Step 1: Add hydrazine hydrate solution and urea into condensation kettle 2. In this step, the hydrazine hydrate solution is a 65-75g / L refined hydrazine hydrate solution, which is obtained from the crude hydrazine hydrate solution output from the reactor through pre-treatment. The specific process of the pre-treatment is to first use circulating water The temperature of the crude hydrazine hydrate solution is cooled to 25-30°C, and then the crude hydrazine hydrate solution is cooled to -3-0°C through the refrigerant, so that a large amount of sodium carbonate in the crude hydrazine hydrate is crystallized as Na 2 CO 3 10H 2 Output in the form of O, and then pass through a centrifuge to remove solid precipitates during cooling, and then obtain a 65-75g / L refined hydrazine hydrate solution. The concentration of the refined hydrazine hydrate solution added in the condensati...

Embodiment 2

[0080] This embodiment provides a preparation method of biurea, comprising the following steps:

[0081] Step 1: add 69.3g / L hydrazine hydrate solution 13m in condensation kettle 2 3 , and 2117Kg of solid urea.

[0082] Step 2: The hydrogen chloride gas generated in the hydrogen chloride synthesis furnace is sent to the condensation kettle 2 through cooling operation, chlorine adsorption operation and pressurization operation in sequence. Firstly, the cooling operation is used to lower the temperature of the hydrogen chloride gas to 100-150°C, and the cooled hydrogen chloride gas undergoes a chlorine adsorption operation to absorb free chlorine therein, so that the free chlorine content in the hydrogen chloride gas is 0.002%.

[0083] It can be seen through chemical equation calculation that in this embodiment, 2046Kg of hydrogen chloride needs to be added to the condensation kettle 2. In order to improve the conversion rate of this reaction, the flow rate of hydrogen chlorid...

Embodiment 3

[0091] This embodiment provides a preparation method of biurea, comprising the following steps:

[0092] Step 1: Add 13m of 71.6g / L hydrazine hydrate solution to condensation kettle 2 3 , and 2187Kg of solid urea.

[0093] Step 2: The hydrogen chloride gas generated in the hydrogen chloride synthesis furnace is sent to the condensation kettle 2 through cooling operation, chlorine adsorption operation and pressurization operation in sequence. First, the cooling operation is used to cool down the hydrogen chloride gas to 100-150°C, and the cooled hydrogen chloride gas undergoes chlorine adsorption operation to absorb free chlorine therein, so that the free chlorine content in the hydrogen chloride gas is 0.001%.

[0094] It can be seen from the calculation of chemical equations that in this embodiment, 2150Kg of hydrogen chloride needs to be added to the condensation kettle 2. In order to improve the conversion rate of this reaction, the flow rate of hydrogen chloride sent into...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com