Preparation method of nitrogen-containing phosphaphenanthrene derivative flame retardant

A technology of derivatives and flame retardants is applied in the field of preparation of nitrogen-containing phosphaphenanthrene derivatives flame retardants, which can solve the problems of harming workers' health, increasing product costs, polluting the environment, etc., and achieving increased production capacity and simple production process. , the effect of simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0023] A preparation method of a nitrogen-containing phosphaphenanthrene derivative flame retardant, comprising the following steps:

[0024] 1) Add 9,10-dihydro-9-oxa-10-phosphaphenanthrene-10-oxide into the reaction kettle and heat to a molten state;

[0025] 2) adding triallyl isocyanurate and a catalyst, stirring and fully reacting to obtain a crude product;

[0026] 3) The crude product is washed, filtered, and dried to obtain DOPO-TAIC, which is a nitrogen-containing phosphaphenanthrene derivative flame retardant.

[0027] Preferably, the molar ratio of triallyl isocyanurate to 9,10-dihydro-9-oxa-10-phosphaphenanthrene-10-oxide is 1: (2-8).

[0028] Preferably, the catalyst is used in an amount of 0.5-5% of the mass of triallyl isocyanurate.

[0029] Preferably, the catalyst is at least one of diacetyl peroxide, methyl ethyl ketone peroxide, dibenzoyl peroxide and tert-butyl hydroperoxide.

[0030] Preferably, the reaction temperature in step 2) is 120-200° C., and th...

Embodiment 1

[0037] 1) Add 28kg of 9,10-dihydro-9-oxa-10-phosphaphenanthrene-10-oxide into a 100L stainless steel reaction kettle with a stirring paddle and a reflux device, stir to raise the temperature to 120°C, and add 10kg Triallyl isocyanurate and 0.075kg methyl ethyl ketone peroxide were reacted at a constant temperature of 120°C for 3 hours;

[0038] 2) Add 10kg of 9,10-dihydro-9-oxa-10-phosphaphenanthrene-10-oxide, and react at a constant temperature of 135°C for 1 hour;

[0039] 3) Add 4.95kg of triallyl isocyanurate and react at a constant temperature of 135°C for 3 hours;

[0040] 4) Add 20kg of 9,10-dihydro-9-oxa-10-phosphaphenanthrene-10-oxide, and react at a constant temperature of 150°C for 0.5 hours;

[0041] 5) Add 0.05kg of triallyl isocyanurate and react at a constant temperature of 150°C for 4 hours to obtain a crude product;

[0042] 6) Pour the crude product into 250kg of propanol after cooling, stir and wash at 60°C, and then filter, place the filtered solid filter...

Embodiment 2

[0044] 1) Add 16.5kg of 9,10-dihydro-9-oxa-10-phosphaphenanthrene-10-oxide into a 20L reaction kettle with stirring paddle and reflux device, stir to raise the temperature to 150°C, add 9.19 kg triallyl isocyanurate, 0.05kg dibenzoyl peroxide and 0.055kg tert-butyl hydroperoxide, stirred at 160°C for 1 hour;

[0045] 2) Add 0.1kg of triallyl isocyanurate, stir and react at a constant temperature of 160°C for 5 hours to obtain a crude product;

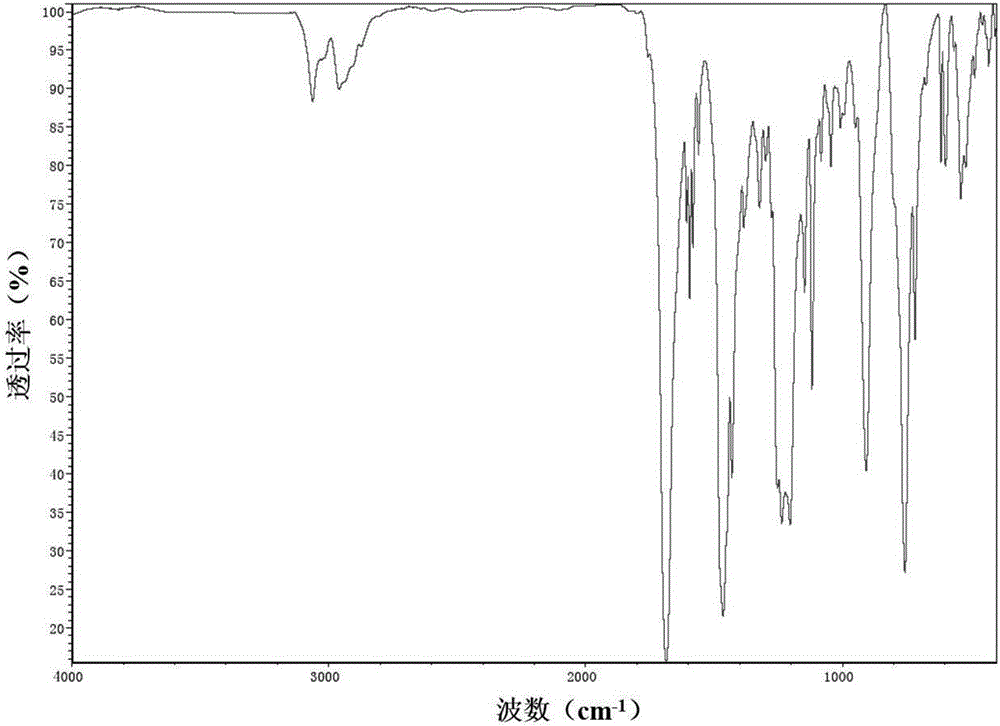

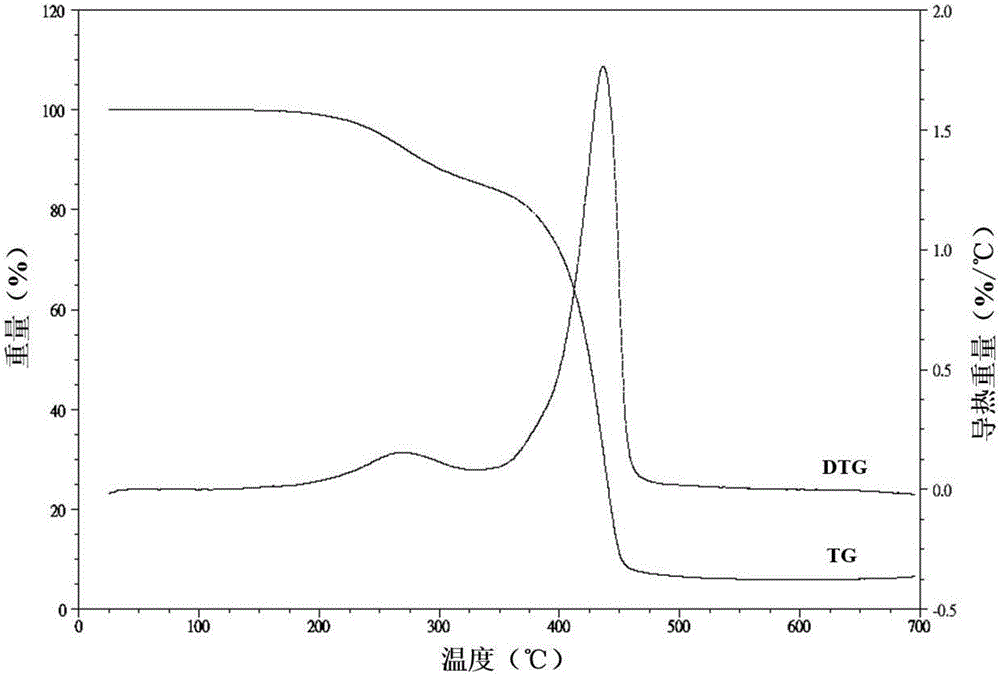

[0046] 3) Pour the crude product into 80kg of ethanol after cooling, stir and wash at 40°C, and then filter, place the filtered solid filter residue in an oven at 80°C to dry to obtain the target product DOPO-TAIC, and the yield of DOPO-TAIC is 86.1 %, the purity of DOPO-TAIC is higher than 95%. The infrared spectrum of the DOPO-TAIC prepared in this embodiment is as follows: figure 1 As shown, the thermogravimetric spectrum is shown as figure 2 shown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com