UV photo-curing elastic self-repairing brightening paint composition

A brightening coating, self-healing technology, applied in the direction of polyurea/polyurethane coatings, coatings, etc., can solve the problem of not showing elastic self-healing performance and scratch resistance performance, no mention of brightening film coating, process complex problems, to achieve the effects of excellent substrate adhesion, excellent wear resistance and scratch resistance, and simple preparation conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Synthetic example 1

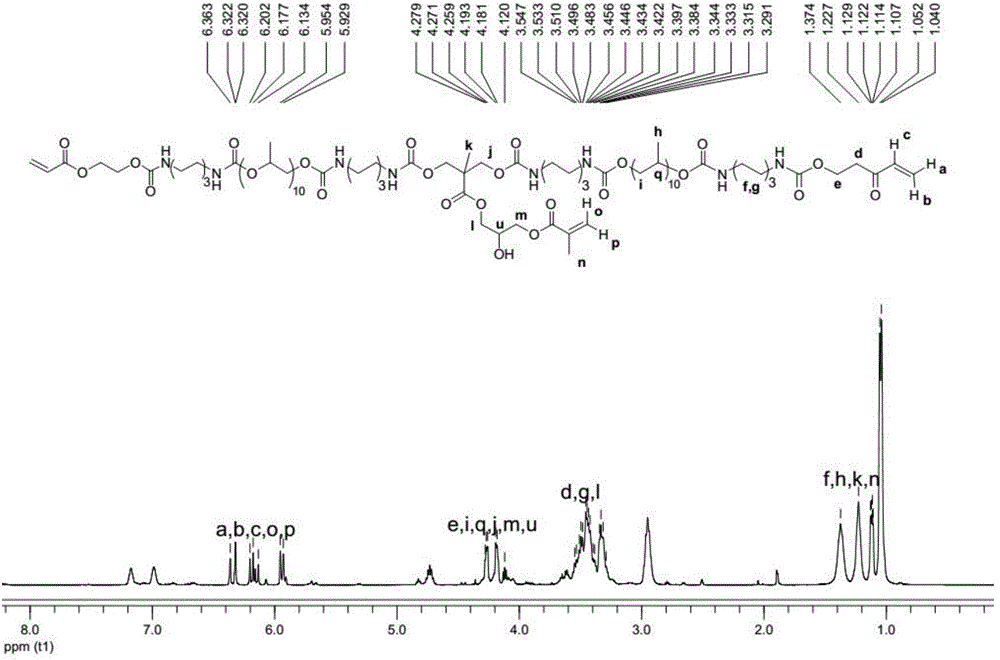

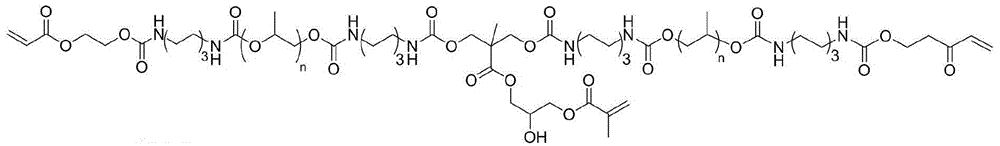

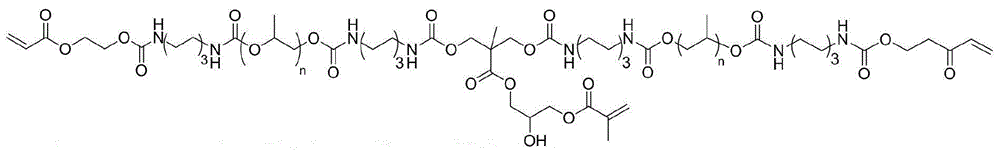

[0039] Synthesis Example 1 This example relates to the synthesis of a trifunctional elastic urethane acrylate A with a hydroxyl group in the side chain

[0040] To a 100 ml four-neck flask equipped with dry nitrogen, mechanical stirring, condenser, thermometer and oil bath heating, add PPG600 (30 g, 0.05 mol) after vacuum dehydration at 100 ° C, and then add hexamethylene di Isocyanate (HDI, 18.7 g, 0.11 mol) and dimethylol propionic acid (DMPA, 0.75 g, 0.0056 mol) were heated up to 75-80°C and reacted for 3 hours. Then the temperature was lowered to 50-55° C., p-hydroxyanisole (0.19 g) and hydroxyethyl acrylate (HEA, 12.90 g, 0.11 mol) were added, and the mixture was reacted for 2 hours. TLC analysis showed that the reaction of hydroxyethyl acrylate was complete. Then add glycidyl methacrylate (GMA, 1.58 grams, 0.011 moles) and catalyst benzyltriethylammonium bromide (0.064 grams), heat up to 90-95 ° C, react for 2-3 hours, TLC analysis to form End the reaction after the g...

Embodiment 1~5

[0052] Examples 1 to 5 respectively provide a UV-curable elastic self-repairing coating composition, and the corresponding raw material components, parts by weight and corresponding performance tests of each composition are shown in Table 1;

[0053] The raw material components corresponding to each example were mixed according to their parts by weight, dispersed at a medium speed for 2 hours, and filtered to obtain the corresponding elastic self-healing UV photocurable coating composition.

[0054] The substances listed in Table 1 are representative of the aforementioned various technical solutions, and are not limited to the substances listed in the table during actual implementation. The monofunctional acrylate can also be selected from phenylthioacrylate, ethoxylated phenoxyacrylate, o-phenylphenethoxyethylacrylate, 2-(p-cumyl-phenoxy)- One or more of hexyl acrylate, 2-hydroxy-3-phenylphenethoxypropyl acrylate, benzyl acrylate, and benzyl methacrylate. The difunctional ac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| refractive index | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com