A kind of high anti-scratch self-repair brightening paint composition

A brightening coating and self-repairing technology, applied in the direction of polyurea/polyurethane coatings, coatings, etc., can solve problems that do not reflect elastic self-repairing performance and scratch resistance of sharp objects, and do not mention brightening film coatings and processes Complicated problems, to achieve good adhesion and wear resistance, good elastic self-healing, simple preparation conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Synthetic example 1

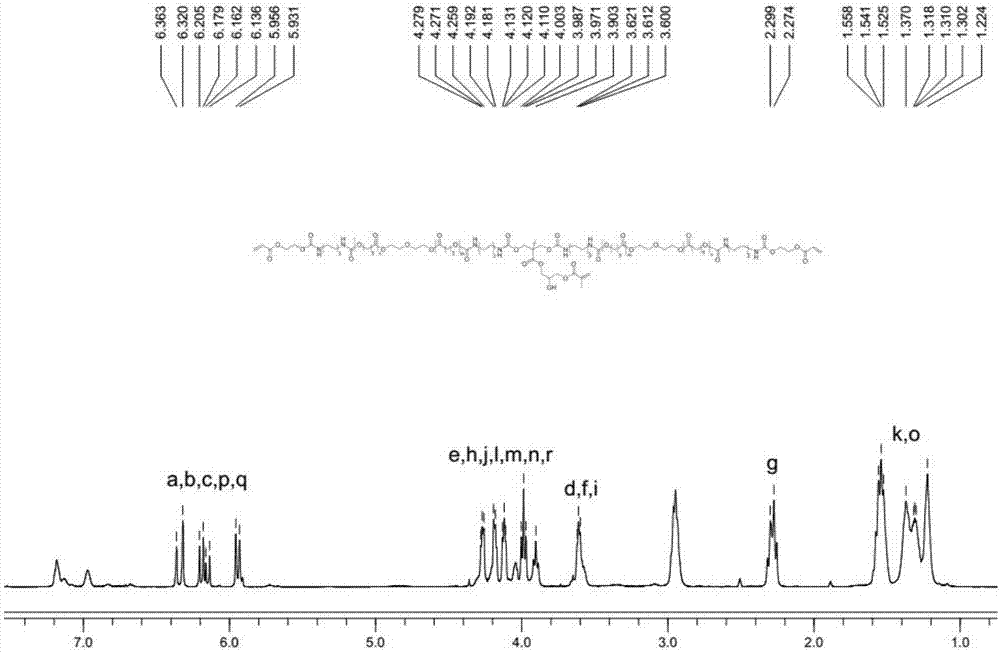

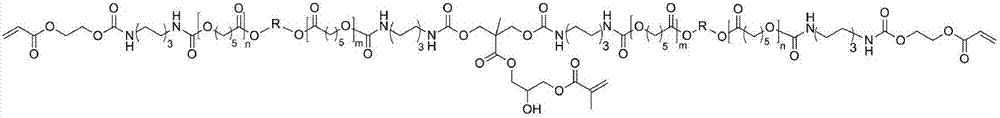

[0043] Synthesis Example 1 This example relates to a trifunctional elastic urethane acrylate A with a hydroxyl group in the side chain. Polycaprolactone diol 500 (PCL500, starting with diethylene glycol, hydroxyl value 211.9 mg KOH / g, 25.0 g, 0.047 mol) after vacuum dehydration at 100°C, and then adding hexamethylene diol Isocyanate (HDI, 18.8 g, 0.11 mol) and dimethylolpropionic acid (DMPA, 0.55 g, 0.0025 mol) were heated up to 80°C and reacted for 3 hours. Then the temperature was lowered to 50-55° C., p-hydroxyanisole (0.18 g) and hydroxyethyl acrylate (HEA, 14.44 g, 0.12 mol) were added, and the mixture was reacted for 2 hours. TLC analysis showed that the reaction of hydroxyethyl acrylate was complete. Then add glycidyl methacrylate (GMA, 0.35 grams, 0.0025 moles) and catalyst benzyltriethylammonium bromide (0.059 grams), heat up to 90 ° C, react for 2 to 3 hours, TLC analysis to methacrylic acid After the glycidyl ester has reacted, the reaction is terminated. A 100% t...

Embodiment 1~5

[0057] Examples 1 to 5 respectively provide a high-scratch-resistant self-repairing brightening coating composition, and the corresponding raw material components, parts by weight and corresponding performance tests of each composition are shown in Table 1;

[0058] The raw material components corresponding to each example were mixed according to their parts by weight, dispersed at a medium speed for 2 hours, and filtered to obtain the corresponding elastic self-healing UV photocurable coating composition.

[0059] The substances listed in Table 1 are representative of the aforementioned various technical solutions, and are not limited to the substances listed in the table during actual implementation. The monofunctional acrylate can also be selected from 2-phenoxy ethyl acrylate, ethoxylated phenoxy acrylate, o-phenylphenethoxy ethyl acrylate, 2-(to-cumyl-benzene One or more of oxy)-hexyl acrylate, 2-hydroxy-3-phenylphenethoxypropyl acrylate, benzyl acrylate, and benzyl metha...

PUM

| Property | Measurement | Unit |

|---|---|---|

| refractive index | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com