Preparation method of chameleon bionic camouflage painting color-changing film

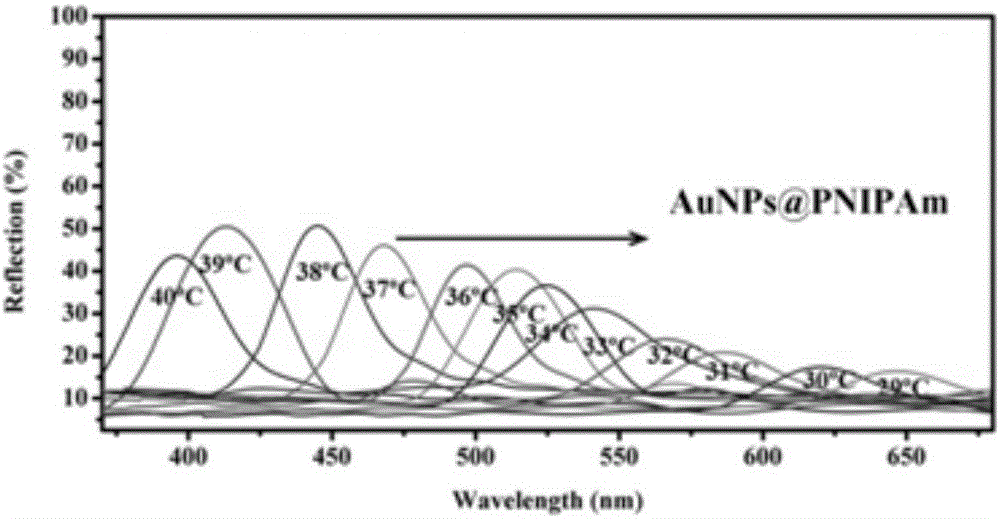

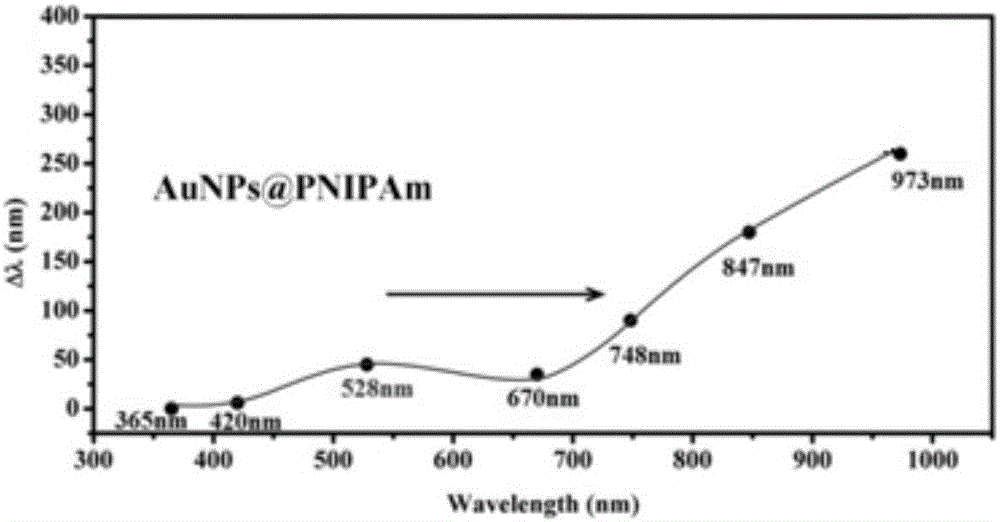

A technology of chameleon and color-changing film is applied in the field of preparation of camouflage color-changing film to achieve the effects of improving photothermal conversion efficiency, enhancing absorption and improving sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] All the reaction containers were ultrasonically cleaned in deionized water for 15 min and repeated four times to fully clean the containers. Prepare thermosensitive polymer monomer solution, including isopropylacrylamide 100g / L, nano gold 1.0×10 9 g / L, polyvinylpyrrolidone 2.0g / L, methylenebisacrylamide 1.0g / L, tetramethylethylenediamine 0.1g / L and ammonium persulfate 0.0001g / L. Stir rapidly at room temperature, and inject 10 μL of it into the photonic crystal template. Stand at room temperature for 30 minutes until the polymerization is complete. Soak the photonic crystal template with the thermosensitive polymer in 50 mL of hydrofluoric acid solution with a mass concentration of 1.5%, and react at room temperature for 6 hours. After the photonic crystal is completely etched, take out the photonic crystal anti-template with thermally sensitive polymer coupling nano-noble metal particles, rinse it repeatedly with deionized water, then soak it in deionized water, chang...

Embodiment 2

[0035] All the reaction containers were ultrasonically cleaned in deionized water for 15 min and repeated four times to fully clean the containers. Prepare thermosensitive polymer monomer solution, including isopropylacrylamide 100g / L, nano gold 2.0×10 9g / L, polyvinylpyrrolidone 4.0g / L, methylenebisacrylamide 2.0g / L, tetramethylethylenediamine 0.2g / L and ammonium persulfate 0.0002g / L. Stir rapidly at room temperature, and inject 10 μL of it into the photonic crystal template. Stand at room temperature for 30 min until the polymerization is complete. Soak the photonic crystal template with the thermosensitive polymer in 50 mL of hydrofluoric acid solution with a mass concentration of 1.5%, and react at room temperature for 6 hours. After the photonic crystal is completely etched, take out the photonic crystal anti-template with thermally sensitive polymer coupling nano-noble metal particles, rinse it repeatedly with deionized water, then soak it in deionized water, change the...

Embodiment 3

[0037] All the reaction containers were ultrasonically cleaned in deionized water for 15 min and repeated four times to fully clean the containers. Prepare thermosensitive polymer monomer solution, including isopropylacrylamide 100g / L, nano gold 3.0×10 9 g / L, polyvinylpyrrolidone 6.0g / L, methylenebisacrylamide 3.0g / L, tetramethylethylenediamine 0.3g / L and ammonium persulfate 0.0003g / L. Stir rapidly at room temperature, and inject 10 μL of it into the photonic crystal template. Stand at room temperature for 30 min until the polymerization is complete. Soak the photonic crystal template with the thermosensitive polymer in 50 mL of hydrofluoric acid solution with a mass concentration of 1.5%, and react at room temperature for 6 hours. After the photonic crystal is completely etched, take out the photonic crystal anti-template with thermally sensitive polymer coupling nano-noble metal particles, rinse it repeatedly with deionized water, then soak it in deionized water, change th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com