Method for preparing photic driving self-repair film based on ethylene-butylene copolymer

A technology of ethylene butene and copolymers, which is applied in the field of self-repair of thin films in the process of dynamic light response, can solve problems affecting work efficiency and dynamic response, and achieve high repair efficiency and simple and easy preparation methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

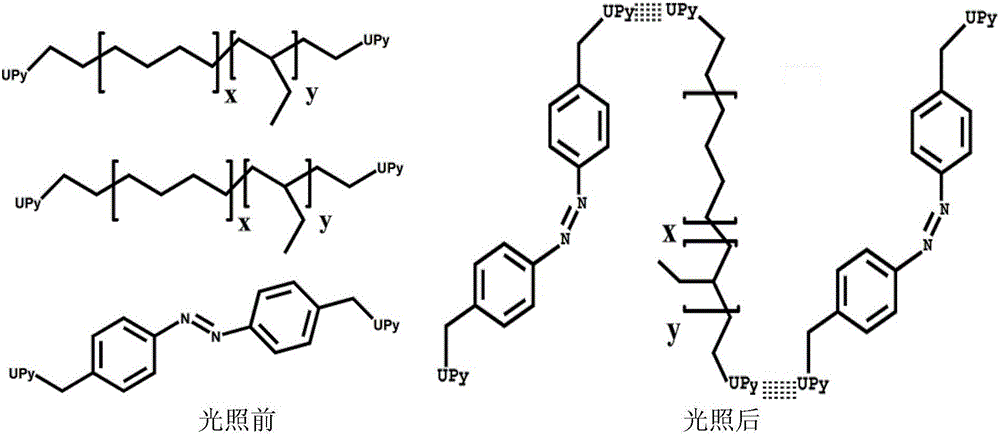

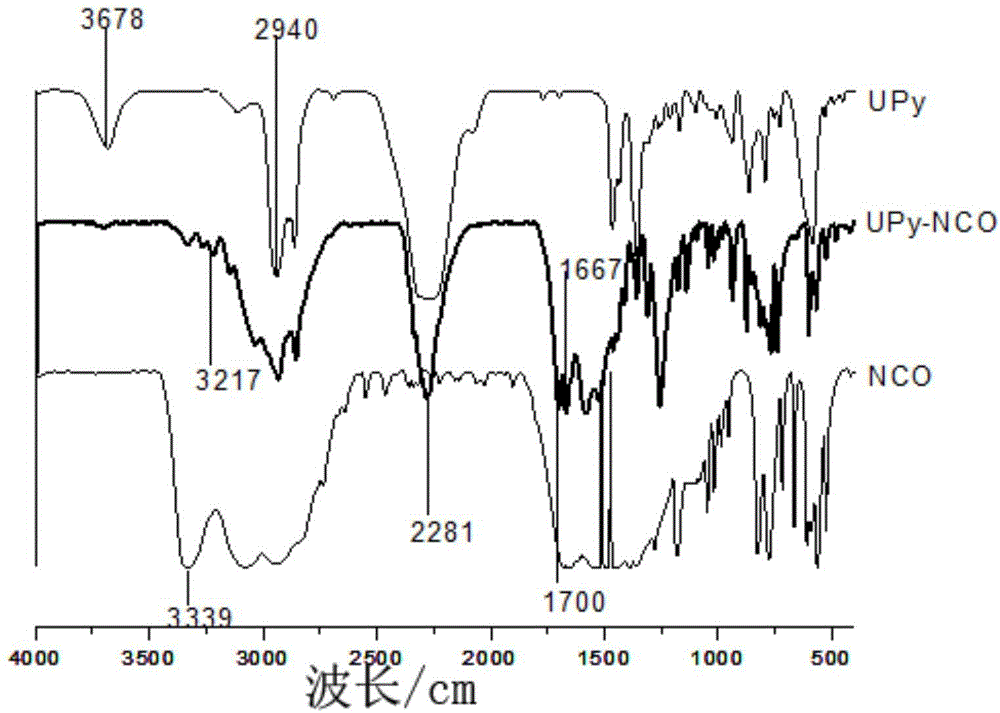

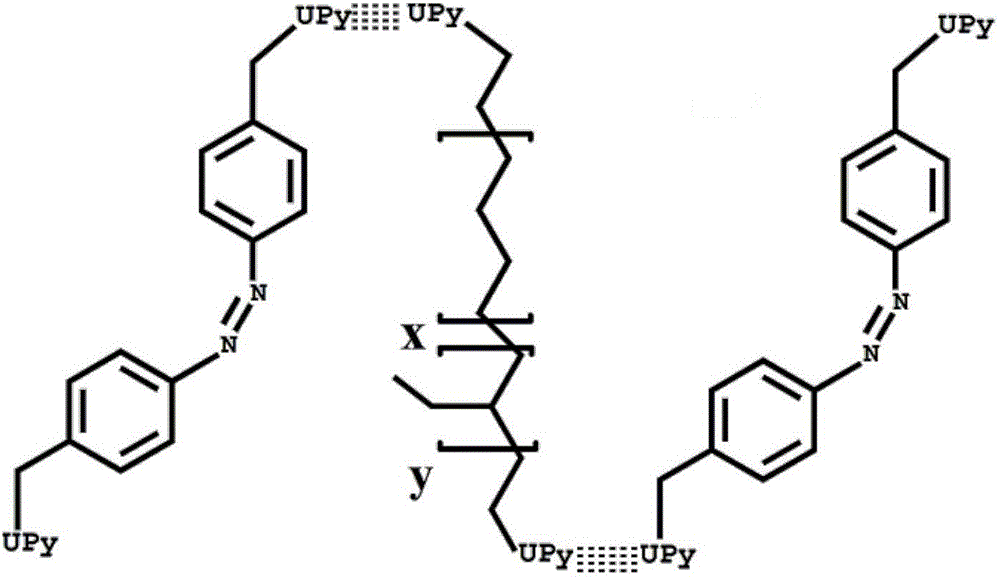

[0044] (1) Put 2-amino-4-hydroxy-6-methylpyrimidine and hexamethylene diisocyanate into a three-necked flask at a ratio of 1:6, and reflux at 100 degrees for 14 hours under nitrogen gas . Add n-pentane to the reactant, and filter with suction several times. The white powder is dried in a vacuum oven at 50°C, and finally 2-ureido-4[1hydrogen]-pyrimidinone with isocyanate group is obtained. Such as figure 1 The amino peak of the shown 2-ureido-4[1hydrogen]-pyrimidinone disappeared, indicating that the reaction of amino and isocyanate groups did occur.

[0045](2) 15mmol number-average molecular weight of 2000g / mol hydroxyl-terminated hydrogenated-1,3-butadiene homopolymer was dissolved in 500ml of chloroform, and the amount of the substance was hydroxyl-terminated hydrogenated-1,3-butadiene 2-ureido-4[1hydro]-pyrimidinone with isocyanate group was added to the above solution, and the mixture was stirred at 60°C for 16h, and then filtered with a large amount of chloroform. Di...

example 2

[0051] (1) Put 2-amino-4-hydroxy-6-methylpyrimidine and hexamethylene diisocyanate into a three-necked flask at a ratio of 1:6, and reflux at 110 degrees for 16 hours under nitrogen. . Add n-pentane to the reactant, and filter with suction several times. The white powder is dried in a vacuum oven at 50°C, and finally 2-ureido-4[1hydrogen]-pyrimidinone with isocyanate group is obtained.

[0052] (2) 15mmol number-average molecular weight of 5000g / mol hydroxyl-terminated hydrogenated-1,3-butadiene homopolymer is dissolved in 500ml of chloroform, and the amount of the substance is hydroxyl-terminated hydrogenated-1,3-butadiene 2-ureido-4[1hydro]-pyrimidinone with isocyanate group was added to the above solution, and the mixture was stirred at 60°C for 16h, and then filtered with a large amount of chloroform. Dibutyltin dilaurate was added in a ratio of 1:150 to the amount of hydroxyl-terminated hydrogenated-1,3-butadiene homopolymer, and then the mixture was stirred at 60°C for...

example 3

[0058] (1) Put 2-amino-4-hydroxy-6-methylpyrimidine and hexamethylene diisocyanate into a three-necked flask at a ratio of 1:6.5, and reflux at 120 degrees for 15 hours under nitrogen. . Add n-pentane to the reactant, and filter with suction several times. The white powder is dried in a vacuum oven at 50°C, and finally 2-ureido-4[1hydrogen]-pyrimidinone with isocyanate group is obtained.

[0059] (2) 17mmol number-average molecular weight of 7000g / mol hydroxyl-terminated hydrogenated-1,3-butadiene homopolymer was dissolved in 500ml of chloroform, and the amount of the substance was hydroxyl-terminated hydrogenated-1,3-butadiene 2-ureido-4[1hydro]-pyrimidinone with an isocyanate group three times the amount of olefin homopolymer was added to the above solution, and the mixture was stirred at 60°C for 16h, and then suction-filtered with a large amount of chloroform. Dibutyltin dilaurate was added in a ratio of 1:200 to the amount of hydroxyl-terminated hydrogenated-1,3-butadie...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Number average molecular weight | aaaaa | aaaaa |

| Number average molecular weight | aaaaa | aaaaa |

| Number average molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com