"Oxygen in water " strong swirl pulverized coal gasifier to prevent burning loss of furnace wall

A gasification furnace, water-in-oxygen technology, applied in the field of coal gasification, can solve the problems of gasification furnace shutdown, economic loss, production line shutdown, etc., and achieve the effect of lower temperature, low temperature and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

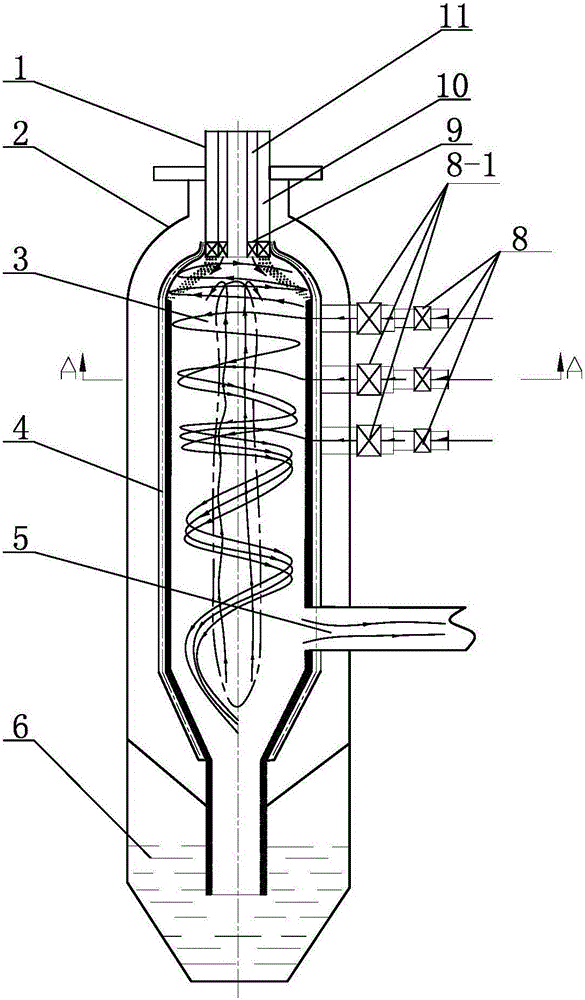

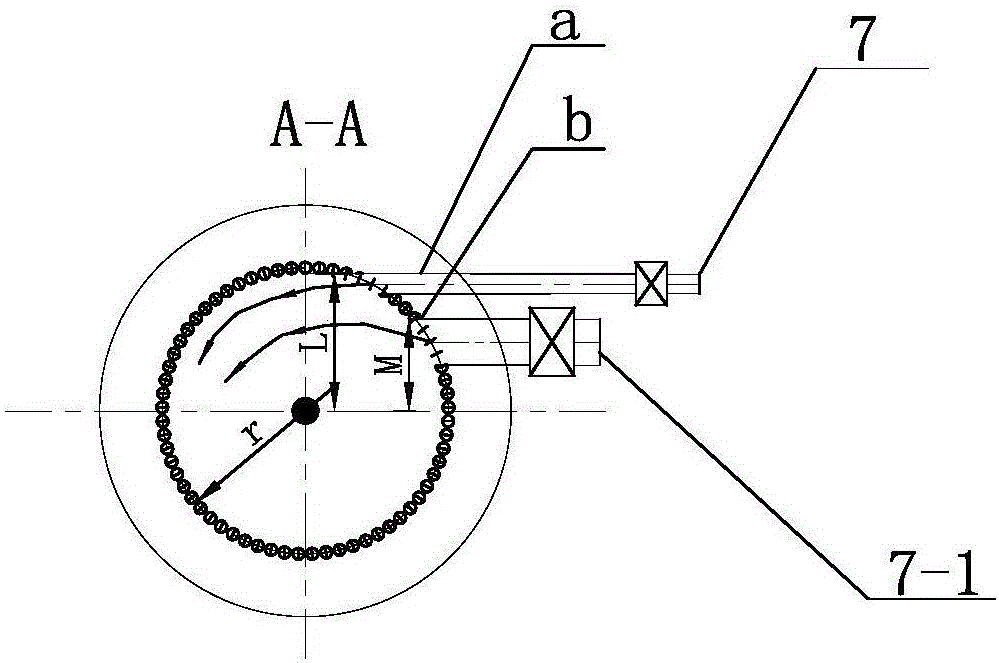

[0008] Specific implementation mode one: combine Figure 1-Figure 2 To illustrate this embodiment, the "oxygen in water" strong rotary pulverized coal gasifier described in this embodiment to prevent furnace wall burnout includes a pulverized coal burner 1, a gasifier body 2, a water wall 4, and a synthetic gas Channel pipe 5, swirl blade 9, multiple water vapor nozzle pipes 7 and multiple oxygen nozzle pipes 7-1, water cooling wall 4 is composed of multiple vertical circular pipes arranged side by side, and water cooling wall 4 is installed on gasification furnace body 2 Inside, the gasification furnace 3 is a revolving body surrounded by water-cooled walls, the bottom of the gasification furnace body 2 is provided with a slag pool 6, and the top of the gasification furnace body 2 is provided with a pulverized coal burner 1, and a pulverized coal burner 1 There is a pulverized coal channel 10 and a water vapor and oxygen mixed gas channel 11 inside, the water vapor and oxygen...

specific Embodiment approach 2

[0009] Specific implementation mode two: combination figure 1 Describe this embodiment, the "oxygen in water" strong rotary pulverized coal gasification furnace described in this embodiment to prevent the furnace wall from burning, the radius of the gasification furnace 3 is r, the value of M is 0.7r, and the value of L is the same as r is equal. In order to maximize the intensity of the swirling flow field in the furnace, make the water vapor flow down close to the furnace wall, effectively protect the water-cooled wall surface, and the other components and connections are the same as the first embodiment.

specific Embodiment approach 3

[0010] Specific implementation mode three: combination figure 1 Describe this embodiment, the "oxygen in water" strong rotary pulverized coal gasifier described in this embodiment to prevent furnace wall from burning, it also includes a plurality of water vapor flow regulating valves 8 and a plurality of oxygen flow regulating valves 8- 1. A steam flow regulating valve 8 is installed on each steam nozzle pipe 7, and an oxygen flow regulating valve 8-1 is installed on each oxygen nozzle pipe 7-1. The water vapor flow in the water vapor nozzle pipe 7 is controlled by the water vapor flow regulating valve 8, and the oxygen flow in the oxygen nozzle pipe 7-1 is controlled by the oxygen flow regulating valve 8-1. Other components and connections are the same as those in the second embodiment.

[0011] working principle

[0012] Oxygen and water vapor enter the water vapor and oxygen mixture gas channel 11 in the pulverized coal burner 1, flow through the swirl blade 9, and then r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com