A method for extracting aroma components of prickly ash and its extract and application

An extraction method and extraction technology, which is applied in the direction of essential oil/fragrance, fat production, etc., can solve the problems of not widely used in industrialization, unaffordable for small enterprises, and high cost of extraction equipment, so as to achieve the retention of heat-sensitive ingredients, strong natural feeling, and aroma good richness effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

experiment example 1

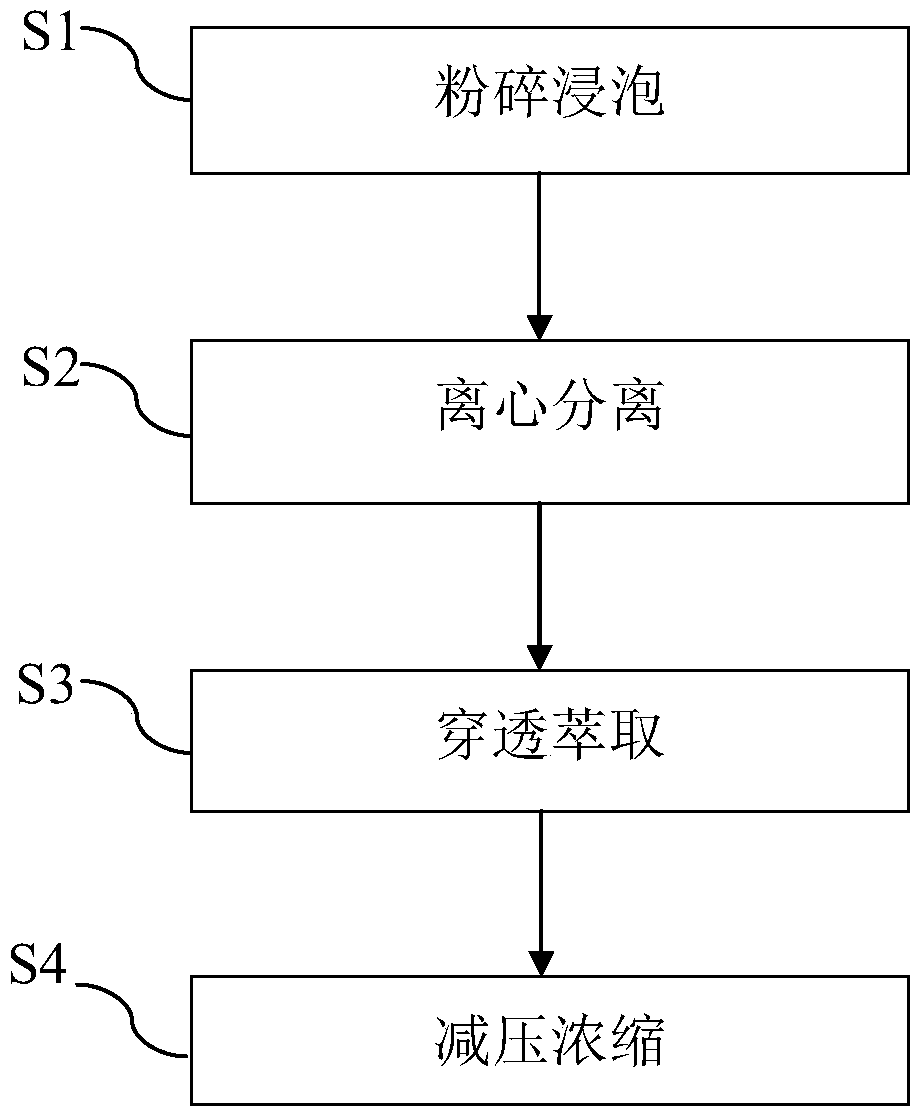

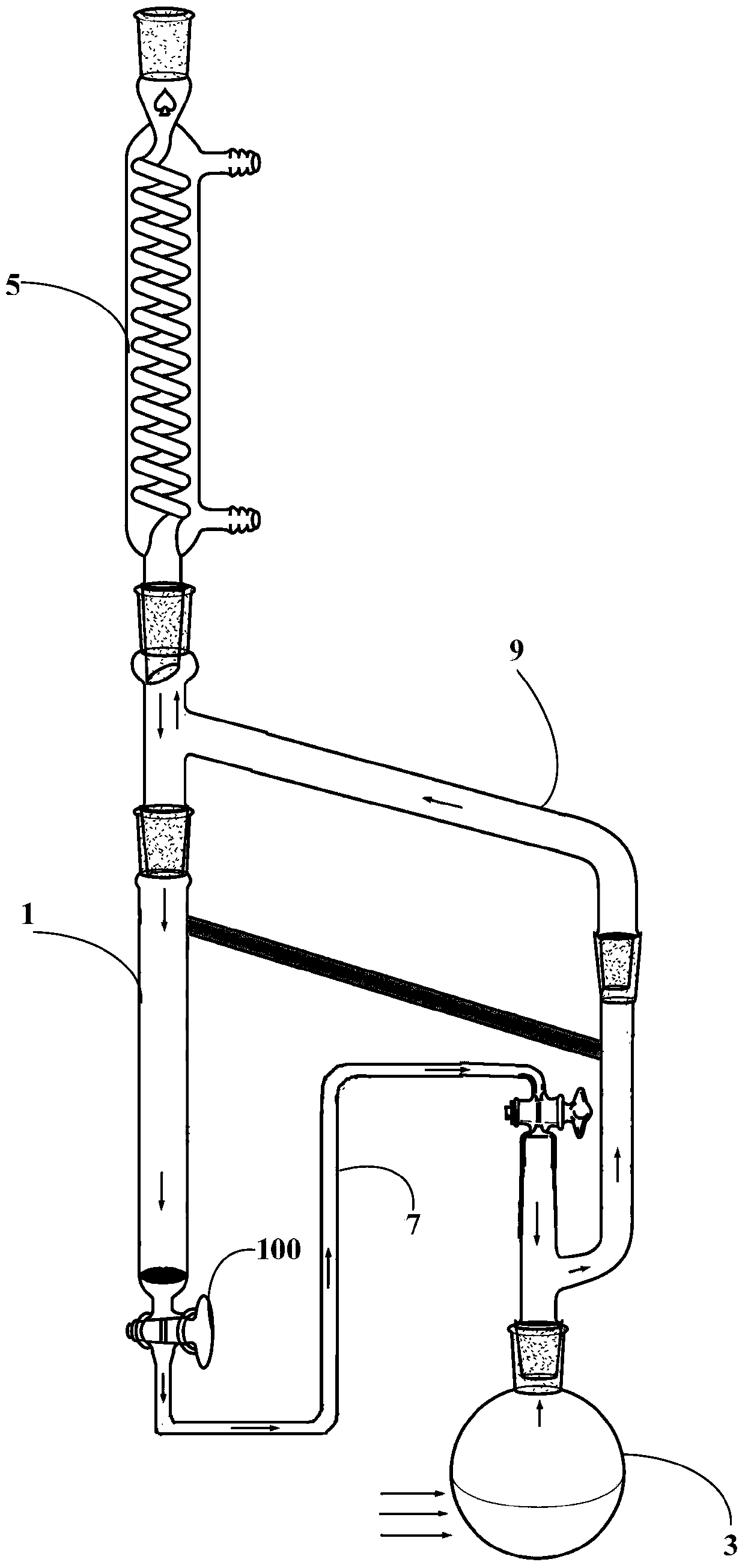

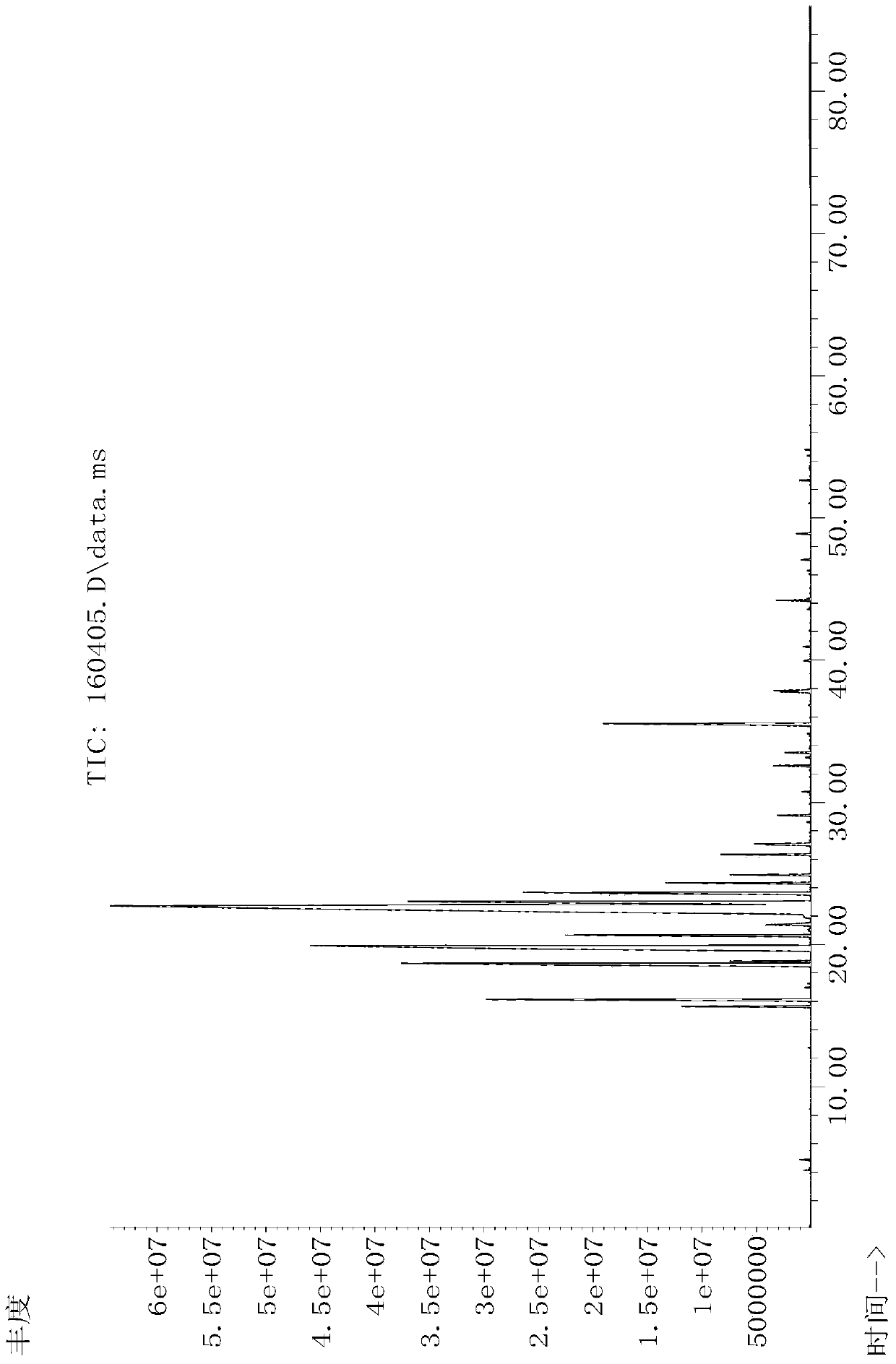

[0030]The Zanthoxylum bungeanum was ultrafinely pulverized to a particle size of 6 μm; 6 times the weight of the Zanthoxylum bungeanum was added in deionized water, soaked for 30 minutes, and then stirred at a speed of 150 rpm, while infrared radiation was carried out for 10 minutes, and the radiation temperature was 60°C. Repeat once and combine the 2 extracts. The extract was centrifuged at 10000 rpm, and the centrifuged supernatant was taken. When extracting, put the supernatant into a cylindrical extraction column filled with glass beads, use chloroform as the extraction solvent, heat at 65°C, pass through the supernatant in the extraction column from top to bottom, and perform breakthrough extraction for 1 hour. After the extraction is completed, the solvent containing the fragrance is concentrated under reduced pressure under the condition of a vacuum of 80 Pa, and after the extraction solvent is removed, the aroma component of Zanthoxylum bungeanum is obtained.

experiment example 2

[0032] The Zanthoxylum bungeanum was ultrafinely crushed to a particle size of 10 μm; 4 times the weight of Zanthoxylum bungeanum was added in deionized water, soaked for 30 minutes, then started stirring at a speed of 120 rpm, and radiated infrared radiation for 6 minutes at a temperature of 75°C. Repeat once and combine the 2 extracts. The extract was centrifuged at 12000 rpm, and the centrifuged supernatant was taken. During extraction, the supernatant is loaded into a cylindrical extraction column filled with glass beads, and dichloromethane is used as the extraction solvent at a heating temperature of 42°C, passing through the supernatant in the extraction column from top to bottom to penetrate the extraction 1.5h. After the extraction is completed, the solvent containing the fragrance is concentrated under reduced pressure under the condition of a vacuum of 40 Pa, and after the extraction solvent is removed, the aroma component of Zanthoxylum bungeanum is obtained.

experiment example 3

[0034] The Zanthoxylum bungeanum was ultrafinely crushed to a particle size of 10 μm; 4 times the weight of Zanthoxylum bungeanum was added in deionized water, and after soaking for 30 minutes, the stirring was started at 150 rpm, and infrared radiation was carried out for 6 minutes at a radiation temperature of 80°C. Repeat once and combine the 2 extracts. The extract was centrifuged at 12000 rpm, and the centrifuged supernatant was taken. During the extraction, the supernatant was loaded into a cylindrical extraction column filled with glass beads, and a mixture of chloroform and dichloromethane with a mass ratio of 1:1 was used as the extraction solvent. The heating temperature was 50°C and passed through from top to bottom The supernatant in the extraction column was subjected to breakthrough extraction for 2 hours. After the extraction, the solvent containing the fragrance is concentrated under reduced pressure under the condition of a vacuum of 60 Pa, and after the extr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com