Aluminum matrix composite and preparation method thereof

An aluminum-based composite material and composite material technology, applied in the field of new material preparation, can solve the problems of poor toughness and low plasticity, and achieve the effects of increased elongation, uniform distribution, and fine grains

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

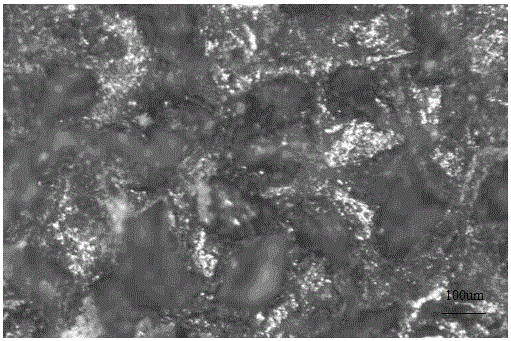

Image

Examples

Embodiment 1

[0018] The invention provides an aluminum-based / three-dimensional connected porous titanium composite material. The composition of the composite material selected in the specific embodiment is: a high-performance aluminum alloy Al-Zn-Mg-Cu currently used for structural materials and a three-dimensional connected porous titanium skeleton . The Al-Zn-Mg-Cu alloy composition (mass percentage) is: 90.5%Al, 6%Zn, 1.5%Mg, 2%Cu, while the porosity of the porous titanium skeleton is 30%, the pore size is 100μm, the purity of titanium 99.9%.

[0019] The present invention provides a method for preparing the above-mentioned aluminum-based / three-dimensional interconnected porous titanium composite material, the specific steps are as follows:

[0020] (1) Ingredients: Al, Zn, Mg and Cu with a purity of not less than 99.9% (mass percentage) were used as the elemental raw materials used in the test. The quality of the above-mentioned elemental raw materials is weighed by a precision elect...

Embodiment 2

[0025] The invention provides an aluminum-based / three-dimensional connected porous titanium composite material. The composition of the composite material selected in the specific embodiment is: a high-performance aluminum alloy Al-Zn-Mg-Cu currently used for structural materials and a three-dimensional connected porous titanium skeleton . The Al-Zn-Mg-Cu alloy composition (mass percentage) is: 90.5%Al, 6%Zn, 1.5%Mg, 2%Cu, and the porosity of the porous titanium skeleton is 80%, the pore size is 50μm, the purity of titanium 99.9%.

[0026] The present invention provides a method for preparing the above-mentioned aluminum-based / three-dimensional interconnected porous titanium composite material, the specific steps are as follows:

[0027] (1) Ingredients: Al, Zn, Mg and Cu with a purity of not less than 99.9% (mass percentage) were used as the elemental raw materials used in the test. The quality of the above-mentioned elemental raw materials is weighed by a precision electron...

Embodiment 3

[0031] The invention provides an aluminum-based / three-dimensional connected porous titanium composite material. The composition of the composite material selected in the specific embodiment is: a high-performance aluminum alloy Al-Zn-Mg-Cu currently used for structural materials and a three-dimensional connected porous titanium skeleton . The Al-Zn-Mg-Cu alloy composition (mass percentage) is: 90.5%Al, 6%Zn, 1.5%Mg, 2%Cu, and the porosity of the porous titanium skeleton is 80%, the pore size is 50μm, the purity of titanium 99.9%.

[0032] The present invention provides a method for preparing the above-mentioned aluminum-based / three-dimensional interconnected porous titanium composite material, the specific steps are as follows:

[0033] (1) Ingredients: Al, Zn, Mg and Cu with a purity of not less than 99.9% (mass percentage) were used as the elemental raw materials used in the test. The quality of the above-mentioned elemental raw materials is weighed by a precision electron...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com