High temperature resistant anti-tearing silicone rubber flexible cable and preparation method thereof

A tear-resistant silicone rubber, flexible cable technology, used in cable/conductor manufacturing, insulated cables, bendable cables, etc. cracking performance, poor wear resistance and other problems, to achieve the effect of superior electrical resistance, excellent mechanical properties, and increased softness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The embodiments of the present invention are described in detail below. This embodiment is implemented on the premise of the technical solution of the present invention, and detailed implementation methods and specific operating procedures are provided, but the protection scope of the present invention is not limited to the following implementation example.

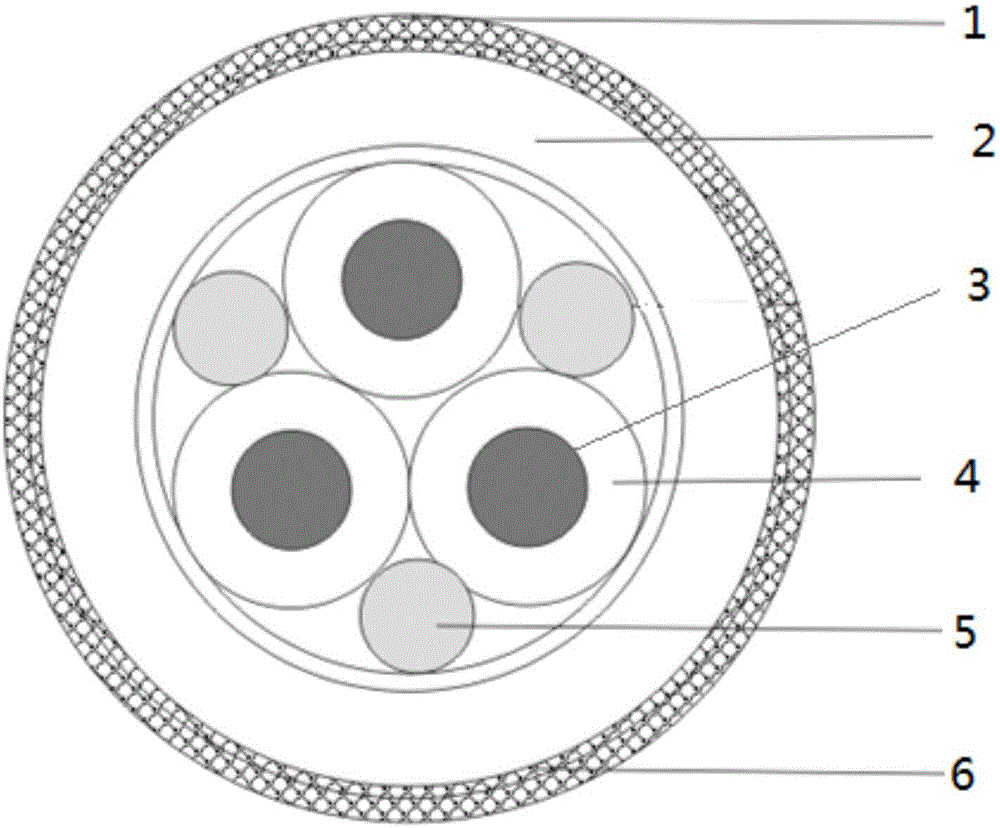

[0029] Please refer to figure 1 , the high-temperature-resistant and tear-resistant silicone rubber flexible cable provided by the present invention includes a cable core, a sheath layer 2 and a braided layer arranged sequentially from the inside to the outside. Filled with glass fiber rope 5, the longitudinal tensile strength of glass fiber rope 5 is greater than 5000Mpa, the tensile modulus is greater than 90Gpa, the rated temperature of glass fiber rope is -50 ~ 200°C, which means the temperature resistance range of the glass fiber rope, Filling with glass fiber rope 5 can not only make the cable structure more...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| area | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com