Hydrophilic/hydrophobic composite multilayer membrane electrode and preparation method thereof

A composite, multi-layer film technology, applied in circuits, fuel cells, electrical components, etc., can solve the problems of increasing the doping amount, reducing the porosity of the catalytic layer, and affecting the mass transfer of the battery, so as to reduce the internal resistance of the battery and expand Gradient distribution of contact angle to achieve the effect of continuity

Active Publication Date: 2019-10-18

上海唐锋能源科技有限公司

View PDF6 Cites 3 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment

[0033] This embodiment relates to a hydrophilic / hydrophobic composite multilayer membrane electrode for a proton exchange membrane fuel cell and a preparation method thereof.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Login to View More

Abstract

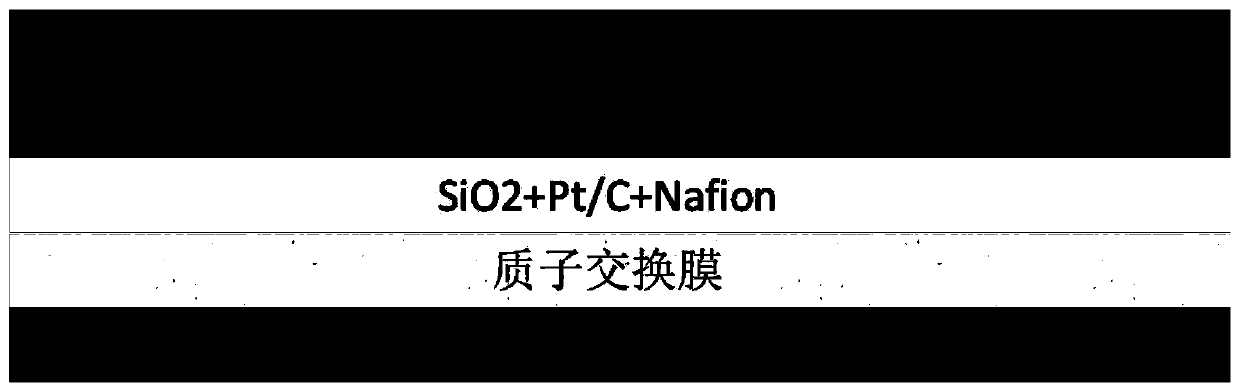

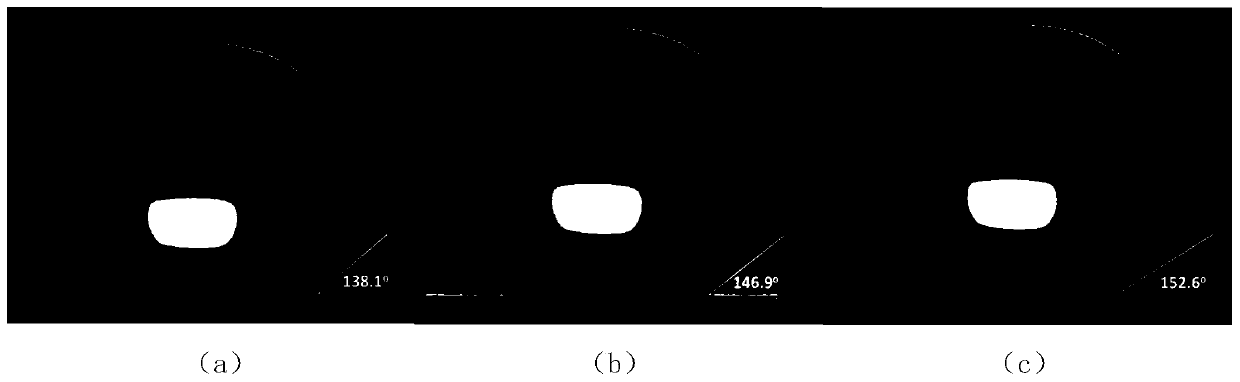

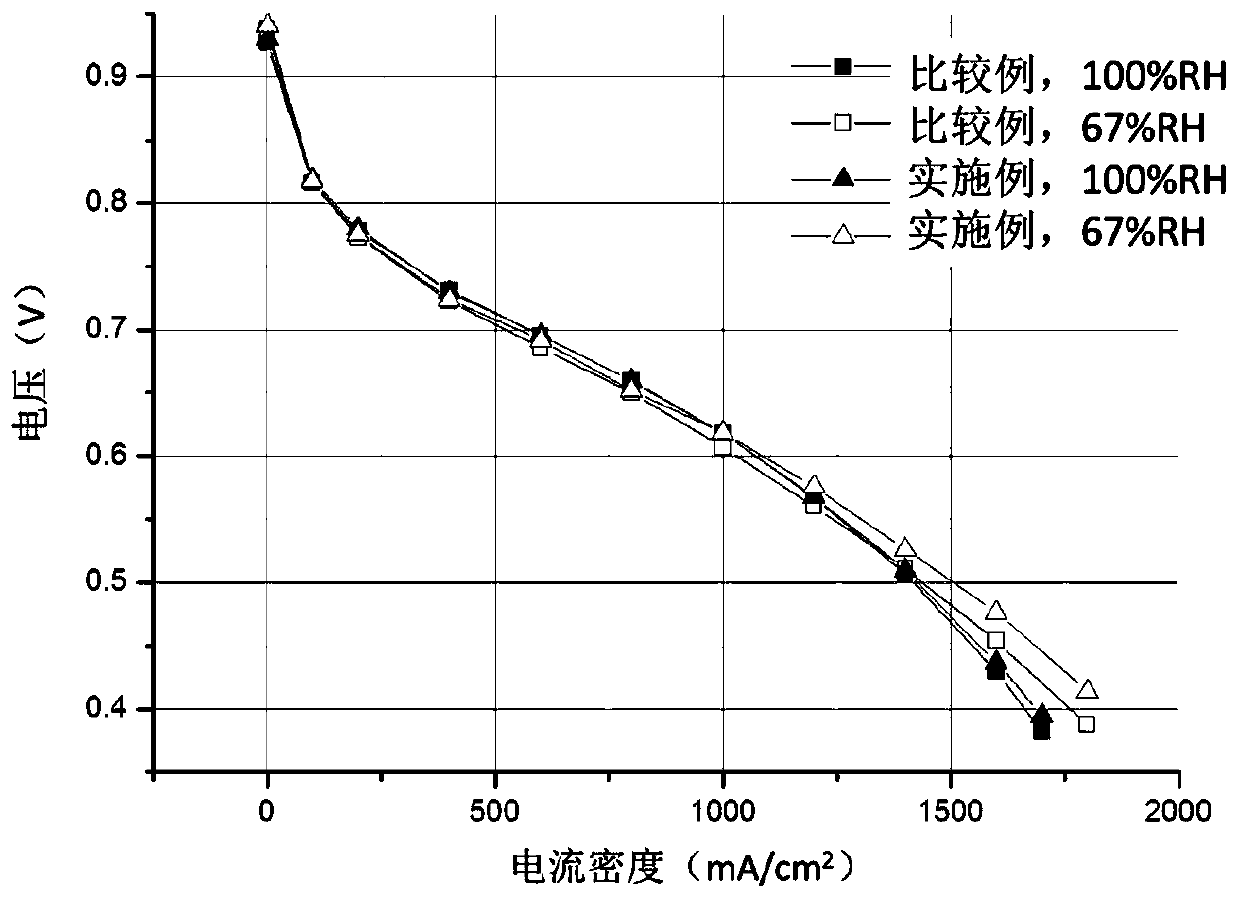

The invention discloses a hydrophilic / hydrophobic compound multilayer membrane electrode and a preparation method thereof. The membrane electrode comprises an anode catalyst layer, a proton exchange membrane, and a cathode catalyst layer, wherein the cathode catalyst layer comprises a three-layer composite structure with a hydrophilic gradient, the layer which is near the proton membrane is a hydrophilic modification layer, the layer which is near a gas diffusion layer is a hydrophobic modification layer, and the middle part between the two layers is a unmodified layer, so that the hydrophilic gradient is formed in the cathode catalyst layer. The hydrophilic layer has moisture retention effects for ionic polymers in the proton exchange membrane and the catalysis layer in a condition with low relative humidity, so that ionic conduction resistance of the membrane electrode is reduced. The hydrophobic layer reduces a capillary pressure gradient between the catalyst layer and the gas diffusion layer, and diffusion of water from the diffusion layer to the catalyst layer in a condition with high relative humidity is inhibited. The scheme is used for realizing the purpose for optimizing water distribution in catalyst layers.

Description

technical field [0001] The invention relates to the technical field of proton exchange membrane fuel cells, in particular to a hydrophilic / hydrophobic composite multilayer membrane electrode for proton exchange membrane fuel cells and a preparation method thereof. Background technique [0002] As the core component of a fuel cell, the membrane electrode includes an anode catalyst layer, a proton exchange membrane and a cathode catalyst layer. It is the reaction site of the fuel cell and realizes the conversion of chemical energy into electrical energy. The catalytic layer of the membrane electrode is mainly porous structure, the reaction gas enters the catalytic layer through the pores to react, and the generated water is discharged from the pores. Under low humidity conditions, the water content in the catalytic layer is less, the conductivity of the proton membrane decreases, and the performance of the battery decreases; under high humidity conditions, liquid water accumul...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): H01M8/1004

CPCH01M8/1004Y02E60/50

Inventor 章俊良王超张卿雷程晓静沈水云朱凤鹃胡宸溢罗柳轩

Owner 上海唐锋能源科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com