Preparation method and application of membrane electrode for improving water management of cathode catalyst layer of proton exchange membrane fuel cell

A fuel cell cathode, proton exchange membrane technology, applied in fuel cells, battery electrodes, electrochemical generators, etc., can solve the problems of reducing the conductivity of the catalytic layer, affecting the life of the membrane electrode, etc., to improve the utilization rate and mass specific activity. , The effect of improving electrochemical active area and mass specific activity and improving porosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

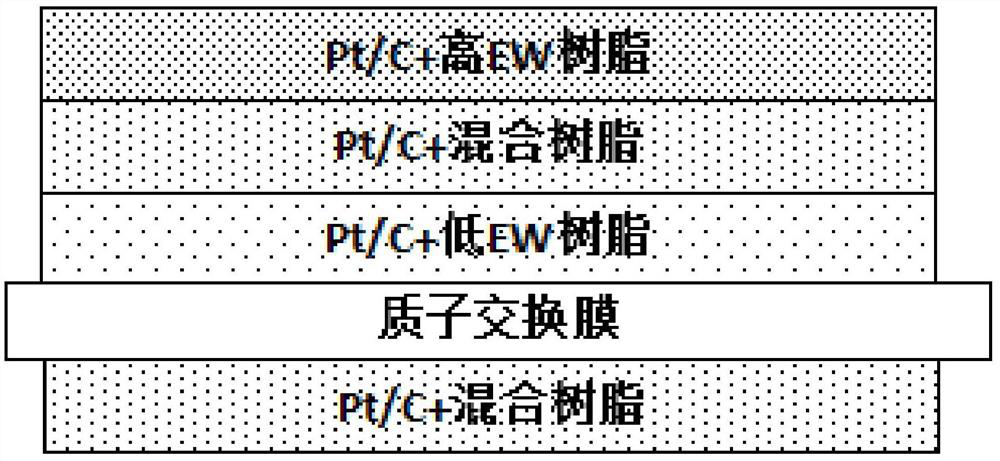

[0038] Prepare three cathode catalyst slurries according to the previous experimental plan; the first layer of catalyst slurries: accurately weigh 3g of catalyst Pt / C with a platinum content of 47%, and add a mass fraction of 10wt% perfluorosulfonic acid resin solution The resin solution I is a perfluorosulfonic acid resin solution of EW700, and then 70 g of low-boiling point alcohol isopropanol and 50 g of deionized water are added in sequence and then ultrasonically mixed for 20 minutes to form the catalytic layer slurry; the second layer Catalyst slurry: Accurately weigh 3g of catalyst Pt / C with a platinum content of 47%, add a mass fraction of 10wt% mixed perfluorosulfonic acid resin solution with a mass of 16 grams, and the resin solution is EW700 and EW1100 with a mass ratio of 1:1 A mixed solution of two perfluorosulfonic acid resins, that is, adding 8 grams of EW700 resin solution and 8 grams of EW1100 resin solution, then adding 70 g of low-boiling point alcohol isopro...

Embodiment 2

[0040] Prepare three cathode catalyst slurries according to the previous experimental plan; the first layer of catalyst slurries: accurately weigh 3g of catalyst Pt / C with a platinum content of 47%, and add a mass fraction of 10wt% perfluorosulfonic acid resin solution The resin solution I is a perfluorosulfonic acid resin solution of EW700, and then 70 g of low-boiling point alcohol isopropanol and 50 g of deionized water are added in sequence and then ultrasonically mixed for 20 minutes to form the catalytic layer slurry; the second layer Catalyst slurry: Accurately weigh 3g of catalyst Pt / C with a platinum content of 47%, add a mass fraction of 10wt% mixed perfluorosulfonic acid resin solution with a mass of 16 grams, and the resin solution is EW700 and EW1100 with a mass ratio of 1:3 A mixed solution of two perfluorosulfonic acid resins, that is, adding 4 grams of EW700 resin solution and 12 grams of EW1100 resin solution, then adding 70 g of low-boiling alcohol isopropanol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com