Preparation method for modified efficient polyaluminum chloride macromolecule inorganic flocculent

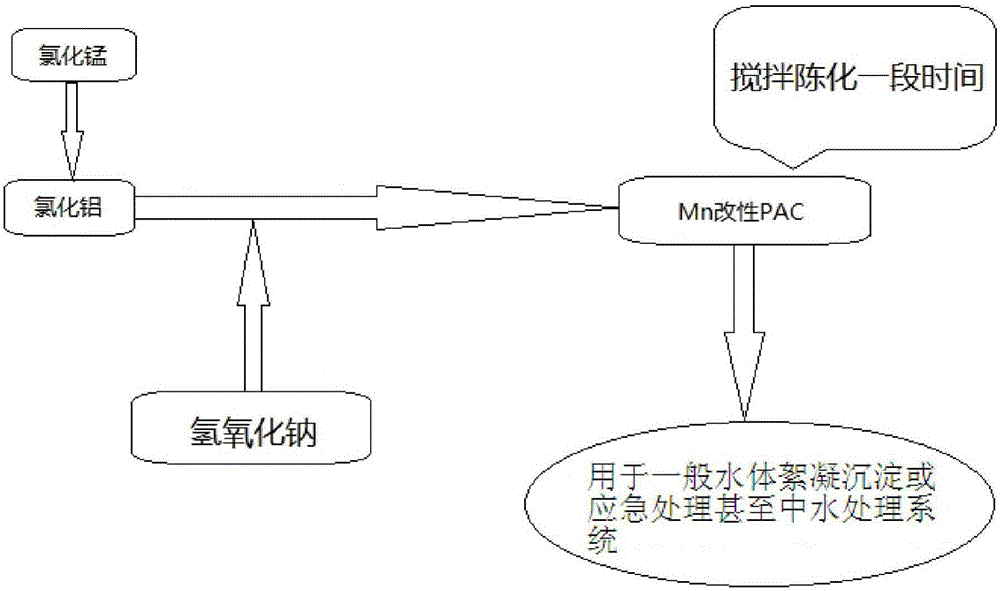

A technology of polyaluminum chloride and inorganic flocculants, which is applied in the fields of chemical instruments and methods, flocculation/sedimentation water/sewage treatment, water/sewage treatment, etc. It can solve the problems of complex preparation process, high cost of modifying agent, and lack of relevant literature. Many problems, to achieve the effect of improving flocculation performance, improving turbidity, and good economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Raw material: AlCL 3 6H 2 O(A.R); NaOH(A.R); MnCl 2 4H 2 O(A.R);

[0029] Configuration of aluminum chloride solution: Accurately weigh 534.0g of 4mol crystalline aluminum chloride (accurate to 0.0001g), dissolve it in 4L aqueous solution, and prepare a 1mol / L aluminum chloride aqueous solution with an accurate concentration. Ready to use after dissolving completely.

[0030] Sodium hydroxide solution configuration: Accurately weigh 480.0g of 12mol crystalline sodium hydroxide (accurate to 0.0001g), dissolve it in 12L aqueous solution, and configure it into a 1mol / L sodium hydroxide aqueous solution with an accurate concentration. Ready to use after dissolving completely.

[0031] Manganese chloride solution configuration: Accurately weigh 1g of 1mol crystalline manganese chloride (accurate to 0.0001g), dissolve it in 1L aqueous solution, and prepare a 1mol / L manganese chloride aqueous solution with precise concentration, and dissolve it at 20-25°C Ready to use ...

Embodiment 2

[0038] Raw material: AlCL 3 6H 2 O(A.R); NaOH(A.R); MnCl 2 4H 2 O(A.R);

[0039] Configuration of aluminum chloride solution: Accurately weigh 801.0g of 6mol crystalline aluminum chloride (accurate to 0.0001g), dissolve it in 6L aqueous solution, and prepare a 1mol / L aluminum chloride aqueous solution with an accurate concentration. Ready to use after dissolving completely.

[0040] Sodium hydroxide solution configuration: Accurately weigh 600.0g of 15mol crystalline sodium hydroxide (accurate to 0.0001g), dissolve it in 15L aqueous solution, and configure it into a 1mol / L sodium hydroxide aqueous solution with an accurate concentration. Ready to use after dissolving completely.

[0041] Manganese chloride solution configuration: Accurately weigh 1g of 1mol crystalline manganese chloride (accurate to 0.0001g), dissolve it in 1L aqueous solution, and prepare a 1mol / L manganese chloride aqueous solution with an accurate concentration, and dissolve it at 20-25°C Ready to ...

Embodiment 3

[0048] Raw material: AlCL 3 6H 2 O(A.R); NaOH(A.R); MnCl 2 4H 2 O(A.R);

[0049] Configuration of aluminum chloride solution: Accurately weigh 667.5g of 5mol crystalline aluminum chloride (accurate to 0.0001g), dissolve it in 5L aqueous solution, and prepare a 1mol / L aluminum chloride aqueous solution with an accurate concentration. Ready to use after dissolving completely.

[0050] Sodium hydroxide solution configuration: Accurately weigh 560.0g of 14mol crystalline sodium hydroxide (accurate to 0.0001g), dissolve it in 14L aqueous solution, and configure it into a 1mol / L sodium hydroxide aqueous solution with an accurate concentration. Ready to use after dissolving completely.

[0051] Manganese chloride solution configuration: Accurately weigh 1g of 1mol crystalline manganese chloride (accurate to 0.0001g), dissolve it in 1L aqueous solution, and prepare a 1mol / L manganese chloride aqueous solution with an accurate concentration, and dissolve it at 20-25°C Ready to ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| color price | aaaaa | aaaaa |

| clearance rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com