Coalbed methane well self-cleaning anti-jamming tube pump

A coalbed methane well and tube pump technology, applied in the direction of variable capacity pump components, pumps, pump components, etc., can solve the problems of affecting the continuity of coalbed methane drainage, increase development costs, plunger wear and loss, etc. Seizure failure occurs, the effect of reducing deposition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

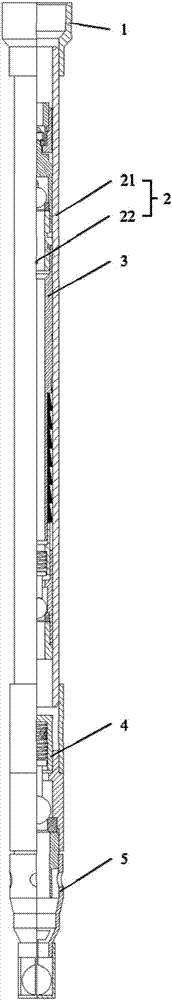

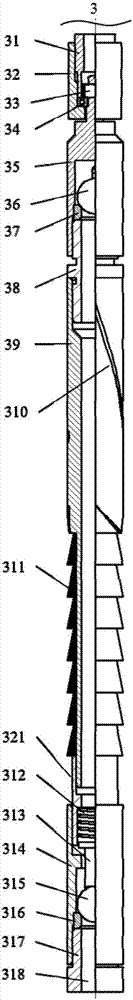

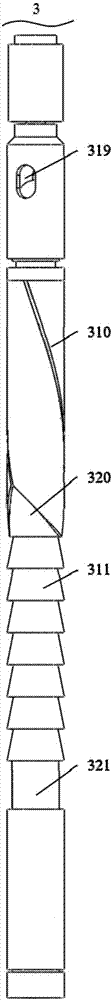

[0024] Such as Figure 1 to Figure 12 As shown, the self-cleaning and anti-jamming pump for coalbed methane wells includes: coupling 1, pump barrel 2, spin-type combined plunger 3, anti-sedimentation fixed valve 4, self-cleaning suction port 5; the upper end of coupling 1 is connected to The lower end of the oil pipe is connected to the top of the pump barrel 2, the spin-type combined plunger 3 is located inside the pump barrel 2, the upper end of the anti-sedimentation fixed valve 4 is connected to the bottom end of the pump barrel 2, and the lower end is connected to the top of the self-cleaning liquid suction port 5; The self-rotating combined plunger 3 adopts a rubber piston structure and an automatic rotating mechanism to reduce the occurrence of plunger stuck faults caused by coal dust and sand particles. The anti-sedimentation fixed valve 4 changes the flow direction of the liquid and performs spiral rapid flushing on the bottom of the pump cylinder 2. To reduce the dep...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com