Formation floating charge method for lithium battery with Li4Ti5O12 negative electrode

A technology of lithium battery and lithium titanate, applied in secondary battery charging/discharging, secondary battery, electrochemical generator, etc. Problems such as high-temperature cycle deviation can be achieved to promote application development, improve cycle and high-temperature performance, and reduce costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

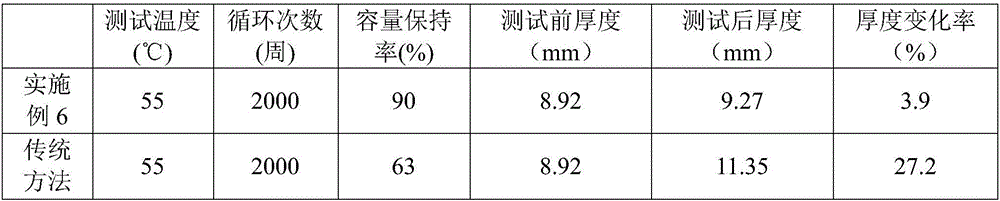

Examples

Embodiment 1

[0023] A lithium titanate negative electrode lithium battery formation float charging method, with nickel cobalt lithium manganese oxide as the positive electrode, with lithium titanate as the negative electrode:

[0024] (1) Formation: At 20°C, charge the lithium titanate negative electrode lithium battery with a constant current of 0.05C to a cut-off voltage of 2.7V, and then charge at a constant voltage to a cut-off current of 0.01C;

[0025] (2) One-time activation: at 50°C, activate the lithium titanate negative electrode lithium battery at high temperature for 72 hours, let it stand for 5 hours, and vacuum pump at a vacuum degree of -0.08MPa;

[0026] (3) Floating charge: The lithium titanate negative electrode lithium battery is charged with a constant current to a cut-off voltage of 2.7V by alternating cycles of small current and micro current, and the number of alternating cycles is 50 times. The small current is 0.05C, and the micro current A current of 0.005C;

[0...

Embodiment 2

[0029] A lithium titanate negative electrode lithium battery formation float charging method, with nickel cobalt lithium manganese oxide as the positive electrode, with lithium titanate as the negative electrode:

[0030] (1) Formation: At 50°C, charge the lithium titanate negative electrode lithium battery with a constant current to a cut-off voltage of 2.7V at a current of 1C, and then charge at a constant voltage to a cut-off current of 0.03C;

[0031] (2) One-time activation: at 80°C, activate the lithium titanate negative electrode lithium battery at high temperature for 24 hours, let it stand for 1 hour, and vacuum pump at a vacuum degree of -0.1MPa;

[0032] (3) Floating charge: at 50°C, the lithium titanate negative electrode lithium battery is charged with a constant current to a cut-off voltage of 2.7V at 50°C with alternating cycles of small current and micro current, the number of alternating cycles is 200, and the small current is 0.5C The current, the micro curre...

Embodiment 3

[0035] A lithium titanate negative electrode lithium battery formation float charging method, with nickel cobalt lithium manganese oxide as the positive electrode, with lithium titanate as the negative electrode:

[0036] (1) Formation: At 38°C, charge the lithium titanate negative electrode lithium battery with a constant current of 0.4C to a cut-off voltage of 2.7V, and then charge at a constant voltage to a cut-off current of 0.02C;

[0037] (2) One-time activation: at 65°C, activate the lithium titanate negative electrode lithium battery at high temperature for 36 hours, let it stand for 2 hours, and vacuum pump at a vacuum degree of -0.06MPa;

[0038] (3) Floating charge: at 38°C, the lithium titanate negative electrode lithium battery is charged with a constant current to a cut-off voltage of 2.7V at 38°C with a small current and a small current alternating cycle, the number of alternating cycles is 100, and the small current is 0.2C The current, the micro current is the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com