External-cavity type narrow-linewidth V-groove fiber bragg grating laser

A fiber grating and narrow linewidth technology, applied in the field of lasers, can solve the problems of low coupling efficiency of waveguide external cavity grating lasers, poor vibration resistance and easy noise generation of fiber grating lasers, and achieve stable structure, low loss, and increased The effect of reflectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

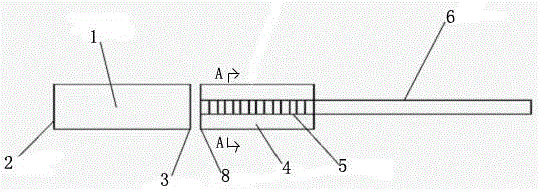

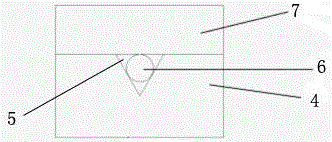

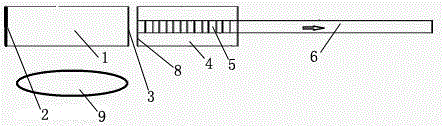

[0018] Example: such as Figure 1-2 As shown, an external-cavity narrow-linewidth V-groove fiber grating laser includes a gain medium 1, a high-reflection coating 2 is placed on one end of the gain medium 1, and an anti-reflection coating I3 is placed on the other end of the gain medium 1. A fiber grating carrier 4 is arranged outside the gain medium 1 and opposite to the anti-reflection film I3. The upper end surface of the fiber grating carrier 4 is provided with a V-shaped groove 5. The included angle of the V-shaped groove 5 is 60 degrees, which is easy to process. .

[0019] One end of the fiber grating 6 is fixed in the V-groove 5 , and the distance from the fiber grating 6 in the V-groove 5 to both sides of the V-groove 5 is equal. And the height of the V-groove is equal to 1.5 times the diameter of the fiber grating, and the negative tolerance is 0.5 μm. This can not only ensure the position of the fiber grating, but also prevent the fiber grating from loosening and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com