Patch preparation

A preparation and patch technology, which is applied in the direction of film/sheet adhesive, adhesive, sheet conveying, etc. The effect of small deviation and high permeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

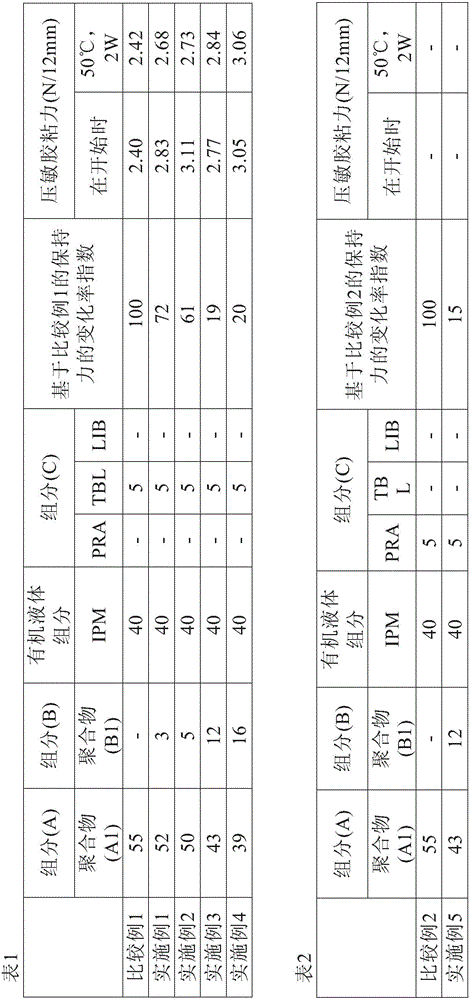

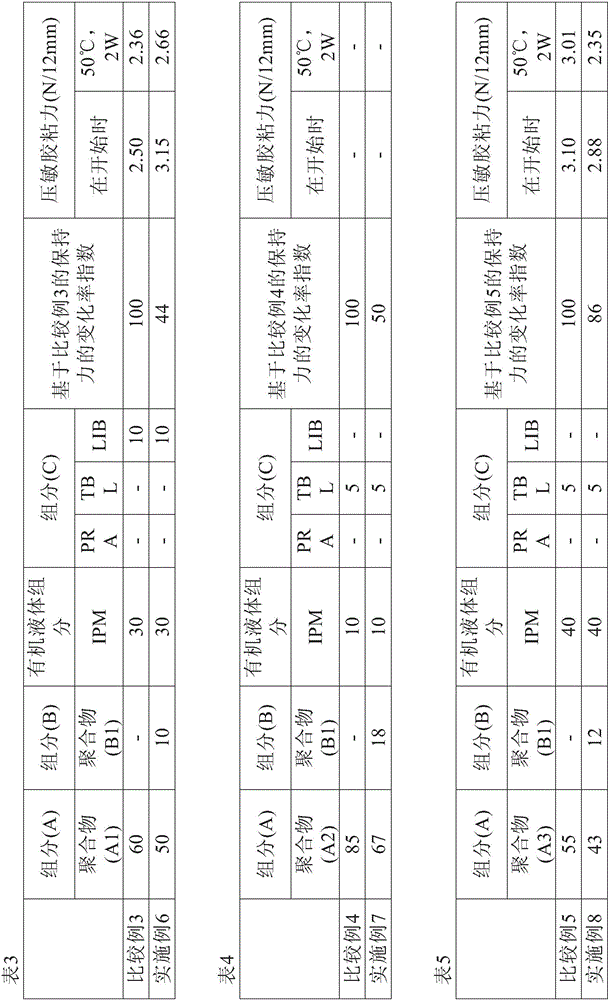

Embodiment 1

[0064] 52 parts by weight (in terms of solid content) as the polymer (A1) of component (A), 3 parts by weight of component (B), 5 parts by weight of tulobuterol as component (C) and 40 parts by weight Parts of isopropyl myristate as an organic liquid component were mixed, and an appropriate amount of ethyl acetate was added for concentration adjustment, and the contents were stirred to obtain a uniform pressure-sensitive adhesive solution. The prepared pressure-sensitive adhesive solution was applied on the release-treated surface of a release sheet made of polyester having a thickness of 75 μm in such a manner that the thickness after drying was 50 μm, followed by drying at 80° C. for 5 minutes to form a pressure-sensitive adhesive layer . Subsequently, a polyester film with a thickness of 4 μm and a film with a thickness of 12 g / m 2 A laminate of nonwoven fabric made of polyester by basis weight was used as a support, and the surface of the nonwoven fabric of the support wa...

Embodiment 2

[0066] Except changing the amount of polymer (A1) as component (A) into 50 parts by weight (in terms of solid content); and changing the amount of component (B) into 5 parts by weight, with the same The patch preparation of the aspect of the present invention was obtained in the same manner.

Embodiment 3

[0068] Except changing the amount of polymer (A1) as component (A) into 43 parts by weight (in terms of solid content); and changing the amount of component (B) into 12 parts by weight, with the same The patch preparation of the aspect of the present invention was obtained in the same manner.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com