Treatment method of high-sulfur content waste water of oil and gas field

A treatment method and high-sulfur technology, applied in water/sewage multi-stage treatment, water/sludge/sewage treatment, combustion methods, etc., can solve the problems of large chemical consumption and waste residue, potential safety hazards, and low efficiency , to achieve the effects of strong environmental adaptability, reduced operating costs, and technical economy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

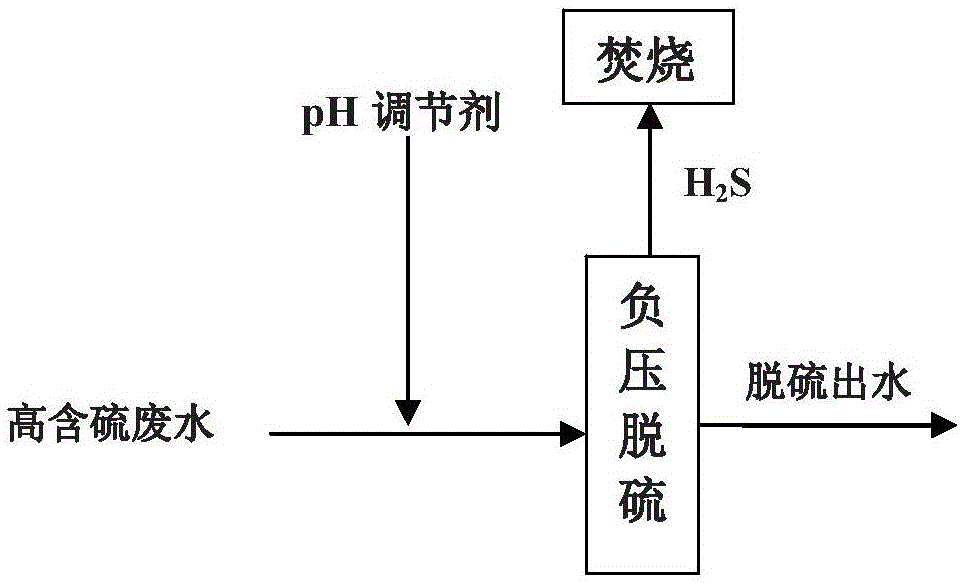

Image

Examples

Embodiment 1

[0031] The main water quality characteristics of the treatment of high-sulfur wastewater from oil and gas fields in this embodiment are: sulfide 2000 mg / L, total dissolved solids 10000 mg / L, and suspended solids 500 mg / L.

[0032] The treatment method of the high-sulfur wastewater from oil and gas fields in this embodiment is as follows: firstly, the pH of the high-sulfur wastewater is adjusted to 6 with sulfuric acid; secondly, the pH-adjusted wastewater is input into a negative pressure desulfurization unit for desulfurization treatment, The operating conditions of negative pressure desulfurization are: inlet water temperature 35°C, operating negative pressure -0.04MPa, hydraulic retention time 20min, reflux ratio of circulating pump 5:1; finally, the hydrogen sulfide produced after negative pressure desulfurization is collected and incinerated deal with.

[0033] The effluent sulfur content of the high-sulfur wastewater from oil and gas fields treated by the above method is...

Embodiment 2

[0035] The main water quality characteristics of treating high-sulfur wastewater from oil and gas fields in this embodiment are: sulfide 5000 mg / L, total dissolved solids 20000 mg / L, and suspended solids 1500 mg / L.

[0036] The treatment method of the high-sulfur wastewater from oil and gas fields in this embodiment is as follows: first, the pH of the high-sulfur wastewater is adjusted to 4.5 by sulfuric acid; secondly, the pH-adjusted wastewater is input into a negative pressure desulfurization unit for desulfurization treatment, The operating conditions of negative pressure desulfurization are: inlet water temperature 40°C, operating negative pressure -0.05MPa, hydraulic retention time 25min, circulation pump reflux ratio 4:1; finally, the hydrogen sulfide produced after negative pressure desulfurization is collected and incinerated deal with.

[0037] The effluent sulfur content of the oil and gas field high-sulfur wastewater treated by the above method is ≤40mg / L. Therefore,...

Embodiment 3

[0039] The main water quality characteristics of treating high-sulfur wastewater from oil and gas fields in this embodiment are: sulfide 10000 mg / L, total dissolved solids 30000 mg / L, and suspended solids 3000 mg / L.

[0040] The treatment method of the high-sulfur wastewater from oil and gas fields in this embodiment is as follows: firstly, sulfuric acid is used to adjust the pH of the high-sulfur wastewater to 5; secondly, the pH-adjusted high-sulfur wastewater is input into a negative pressure desulfurization unit for desulfurization treatment, The operating conditions of negative pressure desulfurization are: inlet water temperature 45°C, operating negative pressure -0.06MPa, hydraulic retention time 30min, circulation pump reflux ratio 3:1; finally, hydrogen sulfide generated after negative pressure desulfurization is collected for incineration deal with.

[0041] The effluent sulfur content of the oil and gas field high-sulfur wastewater treated by the above method is ≤70...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com