Oil-based drilling cuttings extract, extraction method of oil-based drilling cuttings

A technology for oil-based drilling cuttings and extraction liquid, applied in the field of oil-based drilling cuttings extraction and oil-based drilling cuttings extraction liquid, can solve the problems of environmental pollution, strict safety requirements and high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

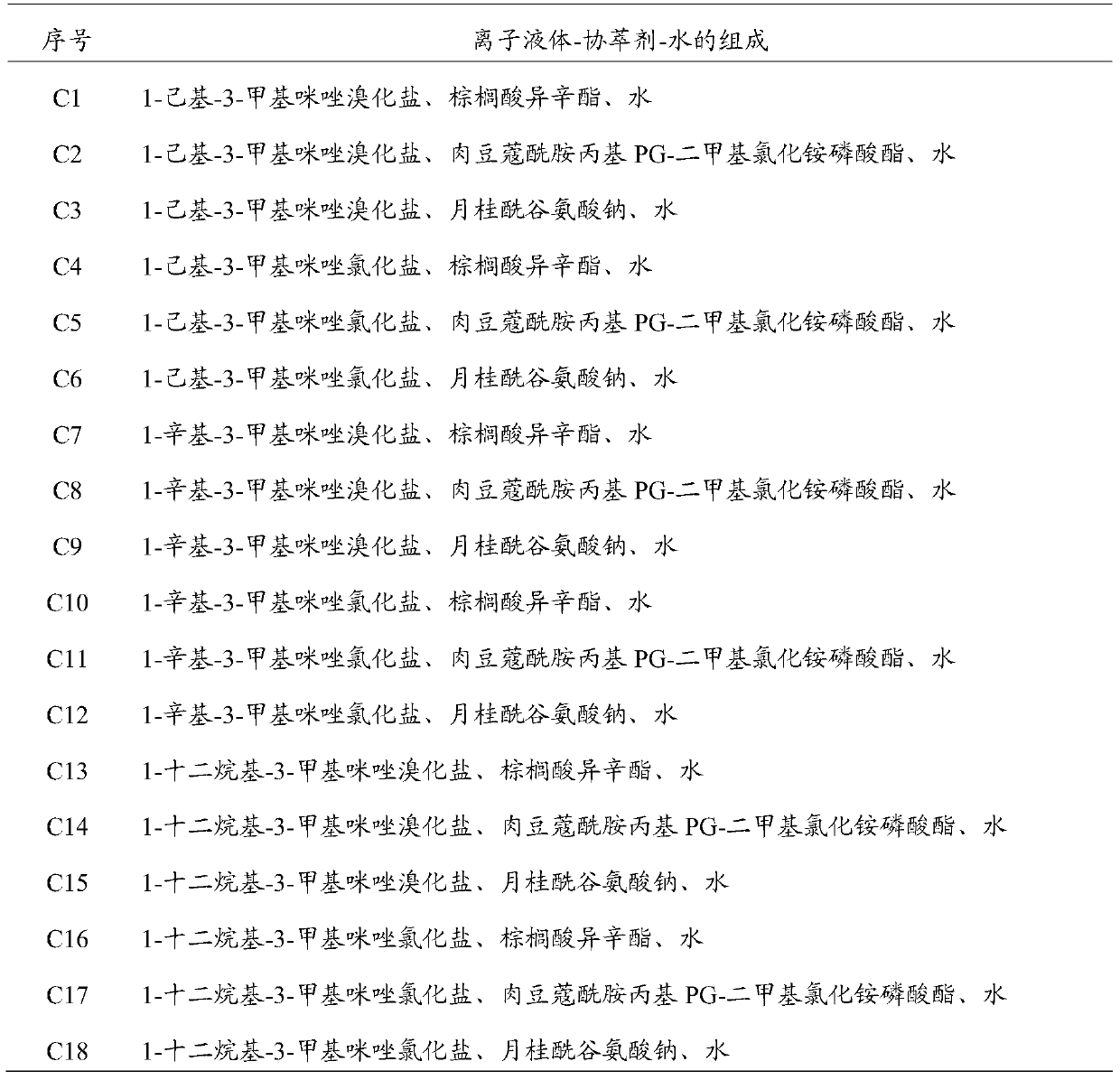

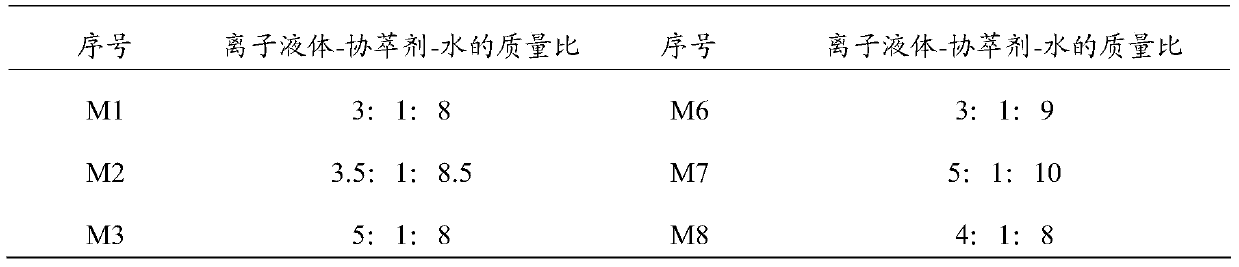

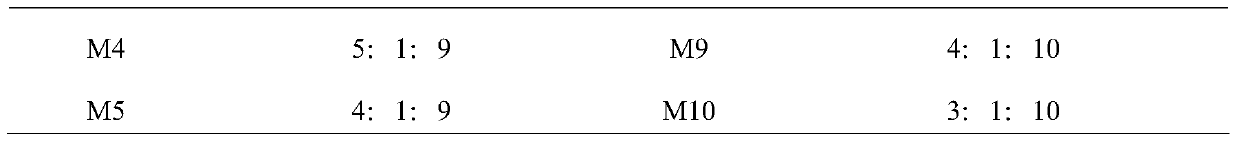

Method used

Image

Examples

Embodiment 1

[0048] 1.1 Put 1000g of oil-based drilling cuttings in an oilfield into a container with a stirring facility, add 1500g of the above-mentioned C1 oil-based drilling cuttings extract with a mass ratio of M1 under constant stirring at a speed of 200rpm, and stir for 3 minutes to obtain solid-liquid The mixture; the solid-liquid mixture was centrifuged at 2500 rpm for 5 minutes to obtain a liquid phase and a solid phase.

[0049] 1.2 Add methanol to the upper liquid phase obtained in 1.1. The mass of methanol is 1% of the mass of the liquid phase, and let stand for 3 minutes to obtain an oil phase and an aqueous phase. The separated aqueous phase can be directly used for the next round of oil-based drilling cuttings extraction, which can be reused 14 times.

Embodiment 2

[0051] 2.1 Put 1000g of oil-based drilling cuttings in an oilfield into a container with a stirring facility, add 2000g of the above-mentioned C5 oil-based drilling cuttings extract with a mass ratio of M3 under constant stirring at a speed of 300rpm, and stir for 5 minutes to obtain a solid-liquid mixture; the solid-liquid mixture was centrifuged at 3500 rpm for 10 min to obtain an upper liquid phase and a lower solid phase.

[0052] 2.2 Add ethanol to the upper liquid phase obtained in 2.1. The mass of ethanol is 1.5% of the mass of the liquid phase, and stand for 4 minutes to obtain an oil phase and an aqueous phase. The separated aqueous phase can be directly used for the next round of oil-based cuttings extraction, which can be reused 15 times.

Embodiment 3

[0054] 3.1 Put 1000g of oil-based drilling cuttings in an oilfield in a container with stirring facilities, and add 1600g of the above-mentioned C5 oil-based drilling cuttings extract with a mass ratio of M5 under constant stirring at a speed of 300rpm, and stir for 5 minutes to obtain solid-liquid The mixture; the solid-liquid mixture was centrifuged at 3000 rpm for 8 minutes to obtain a liquid phase and a solid phase.

[0055] 3.2 Add butanol to the liquid phase obtained in 3.1, the mass of butanol is 2% of the mass of the upper liquid phase, and let it stand for 5 minutes to obtain an oil phase and a water phase. The separated aqueous phase can be directly used for the next round of oil-based drilling cuttings extraction, which can be reused 16 times.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com