Preparation method of vascular anastomosis agent

A blood vessel and mixture technology, which is applied in the field of vascular anastomosis preparation, can solve the problems of no suitable concentration method, high solid content, high viscosity of the vascular anastomosis agent, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0033] The invention discloses a preparation method of a vascular anastomotic agent, and those skilled in the art can learn from the content of this article and appropriately improve the process parameters to realize it. In particular, it should be pointed out that all similar replacements and modifications are obvious to those skilled in the art, and they are all considered to be included in the present invention. The method and application of the present invention have been described through preferred embodiments, and the relevant personnel can obviously make changes or appropriate changes and combinations to the method and application described herein without departing from the content, spirit and scope of the present invention to realize and Apply the technology of the present invention.

[0034] The reagents or instruments used in the preparation method of the vascular anastomotic agent provided by the present invention can be purchased from the market.

Embodiment 1

[0037] Dosing: Take 9.96L of water for injection, add 40g of ethyl cellulose (Natrosol, Ashland_Aqualon) under stirring, the rotation speed of the main stirring paddle is 70-100rpm, the rotation speed of the emulsification flying knife is 2500rpm, emulsify and disperse for 1h, and obtain 0.4% (w / w ) ethyl cellulose aqueous solution.

[0038] Sterilization by filtration: pass 0.4% ethyl cellulose aqueous solution through 0.45 micron and 0.22 micron filter membranes successively to sterilize.

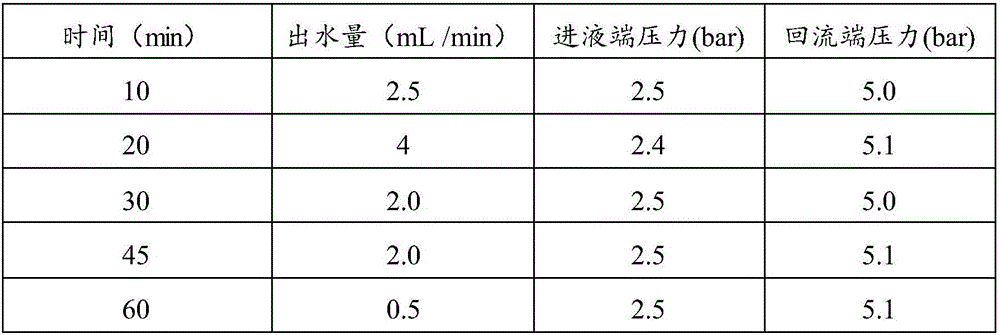

[0039] Concentration by ultrafiltration: Use tangential flow ultrafiltration to remove water from the 0.4% ethylcellulose aqueous solution that has been sterilized by filtration. The molecular weight cut-off of the membrane bag is 5000KD, provided by Millipore. higher than the dissolution temperature), control the water output at 4-25mL / min, adjust the pressure at the inlet end to 2-5bar, and the pressure at the return end to 2-3bar. The water output changes with time as shown in the foll...

Embodiment 2

[0063] Dosing: Take 9.94L of water for injection, add 60g of chitosan (4000KD, Jinke Pharmaceutical) under stirring, the rotation speed of the main stirring paddle is 70-100rpm, the rotation speed of the emulsifying flying knife is 0rpm, and add 1mol / l hydrochloric acid solution to adjust the pH to 3-4, stirred for 1.5h to obtain 0.6% (w / w) chitosan aqueous solution.

[0064] Sterilization by filtration: Sterilize 0.6% chitosan aqueous solution through 0.45 micron and 0.22 micron filter membranes successively.

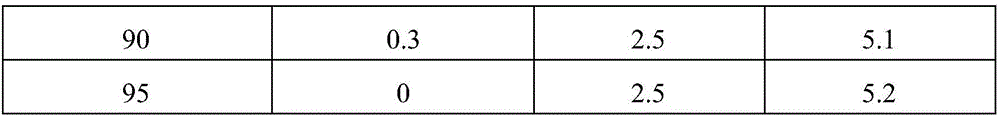

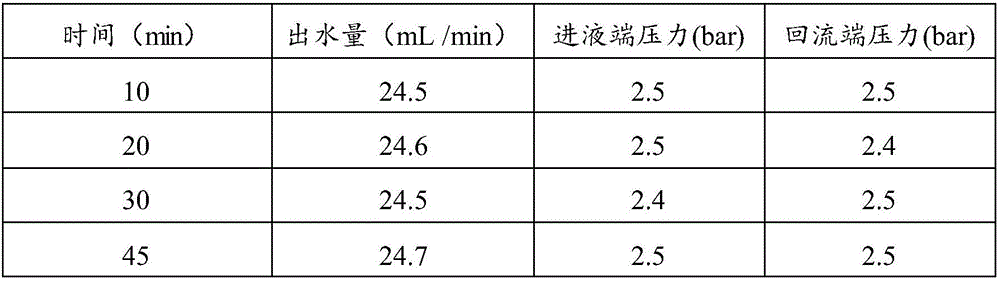

[0065] Concentration by ultrafiltration: The 0.6% chitosan aqueous solution that has been sterilized by filtration is removed by tangential flow ultrafiltration. The molecular weight cut-off of the membrane bag is 10000KD, provided by Millipore. 10°C, control the water output at 5-26mL / min, adjust the pressure at the liquid inlet to 3 bar, and the pressure at the return end to 2.5 to 3.0 bar. The water output changes with time as shown in the following table:

[0066]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com