Preparation method of composite material thin-walled shell based on discontinuous layup

A technology of thin-walled shells and composite materials, which is applied in the field of composite material structure design and composite material processing technology, can solve the problems of easy deformation of thin-walled shells, and achieve the effects of small deformation, short production cycle and good applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

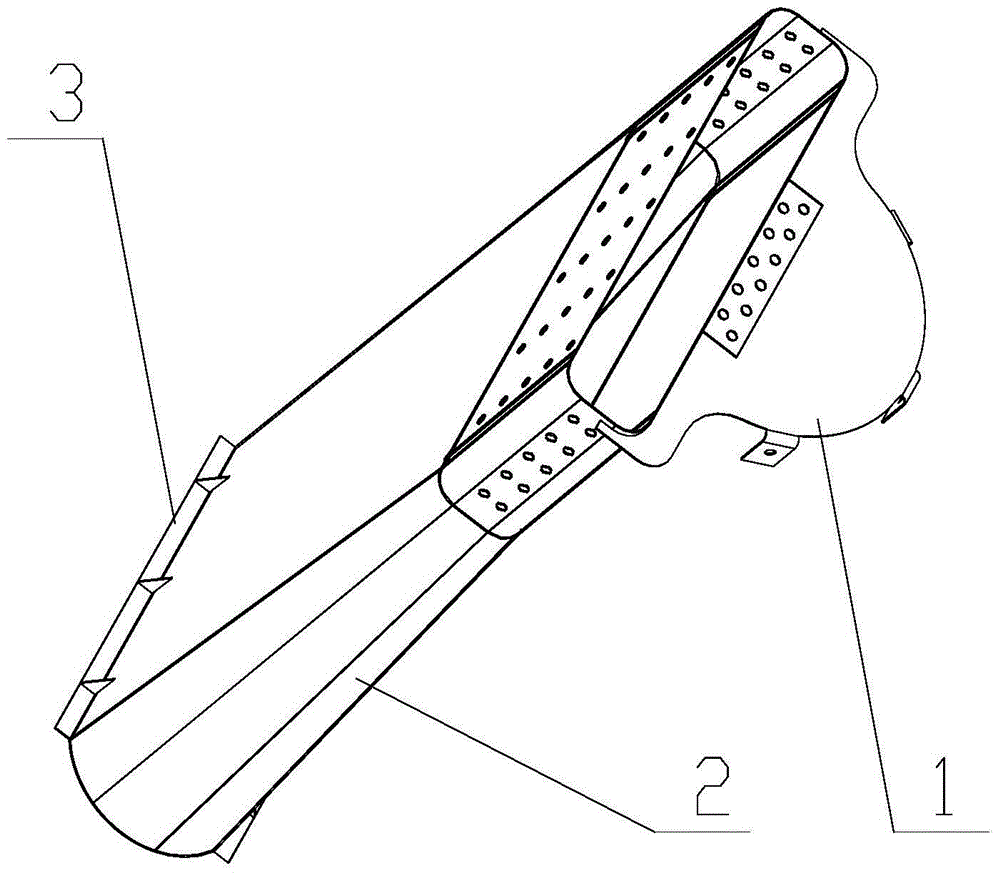

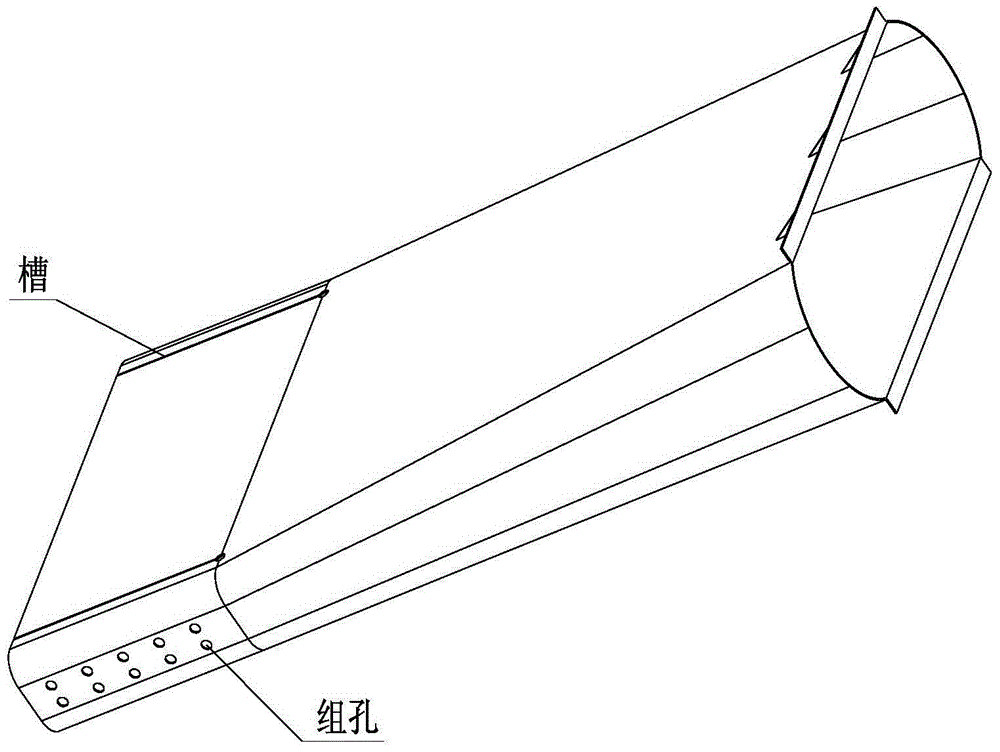

[0044] The cover body 2 adopts the discontinuous lay-up method, which greatly simplifies the structure of the inner cover, effectively controls its maximum deformation, and saves the reinforcing rib 3 at the far end of the cover body 2 at the same time. The structural representation of the cover body 2 without ribs 3 is as follows: Figure 4 shown.

[0045] The first step is to design and manufacture the forming mold of the cover body 2. The mold is a positive mold, and the mold is made of metal material. The external dimensions of the mold are consistent with the inner cavity of the cover body 2; mold release agent, and dry it; the fluorocarbon release agent can be replaced by other release agents with a temperature resistance not lower than 140°C; if necessary, the mold can be heated to 50-60°C.

[0046] The second step is to prepare Kevlar49 / 8D-1 plain fabric prepreg with a nominal thickness of 0.1mm. The resin content of the prepreg is controlled at 42±5%, and the volatil...

Embodiment 2

[0057] The cover body 2 adopts the discontinuous lay-up method, which greatly simplifies the structure of the inner cover, effectively controls its maximum deformation, and saves the reinforcing rib 3 at the far end of the cover body 2 at the same time. The structural representation of the cover body 2 without reinforcing rib 3 is as follows: Figure 4 shown.

[0058] The first step is to design and manufacture the forming mold of the cover body 2. The mold is a female mold, and the mold is made of metal material. The shape and size of the inner cavity of the mold are consistent with the outer surface of the cover body 2; before use, a layer of fluorine is applied to the working surface of the mold. Carbon compound release agent, and dry it; the fluorocarbon release agent can be replaced by other release agents with a temperature resistance not lower than 140°C; if necessary, the mold can be heated to 50-60°C.

[0059] The second step is to prepare Kevlar49 / 8D-1 plain fabric ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com