Bone cement with high heat generating efficiency

A technology of bone cement and thermal efficiency, applied in the field of biomedicine, can solve the problems of low heating efficiency, side effects, and large amount of magnetic nanoparticles, and achieve the effect of reducing the amount of addition and high heating efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

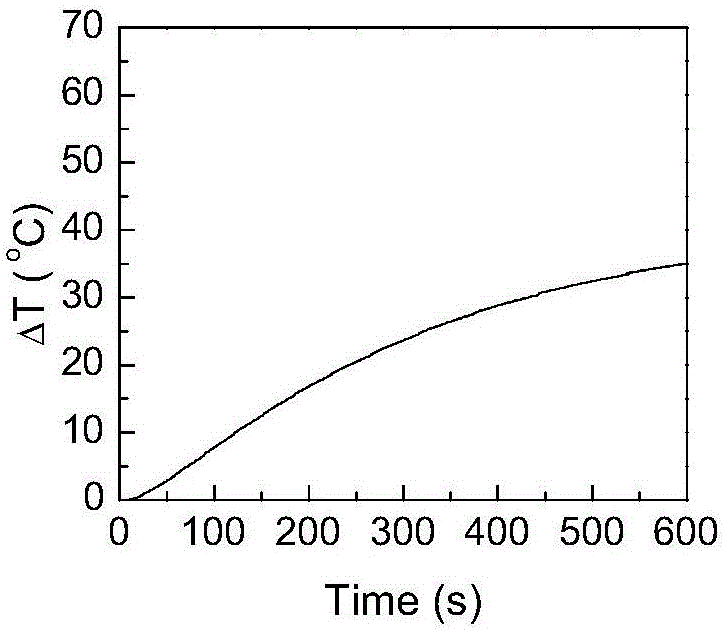

Embodiment 1

[0036] This embodiment relates to a bone cement with high heat production efficiency, the bone cement raw material is PMMA, and 0.5% magnetic nanoparticle Zn is added therein 0.7 Fe 2.3 o 4 ;

[0037] The present embodiment also relates to the preparation method of this magnetic bone cement, comprising the following steps:

[0038] 1) Place PMMA, MMA and magnetic nanoparticles at 23°C and a relative humidity of 40%-50% for more than 2h,

[0039] 2) Weigh 1.99g of PMMA powder and place it in a crucible, weigh 0.01g of magnetic nanoparticles, and dissolve the magnetic nanoparticles in 1ml of MMA solution, ultrasonically disperse the particles uniformly in the solution, and then dissolve the magnetic nanoparticles The mixed solution was injected into a crucible filled with PMMA powder and mixed evenly.

[0040] 3) Transfer the mixed mixture to a cylindrical mold with a diameter of 6 mm and a height of 12 mm for about 10 minutes, after it is completely polymerized, demould.

...

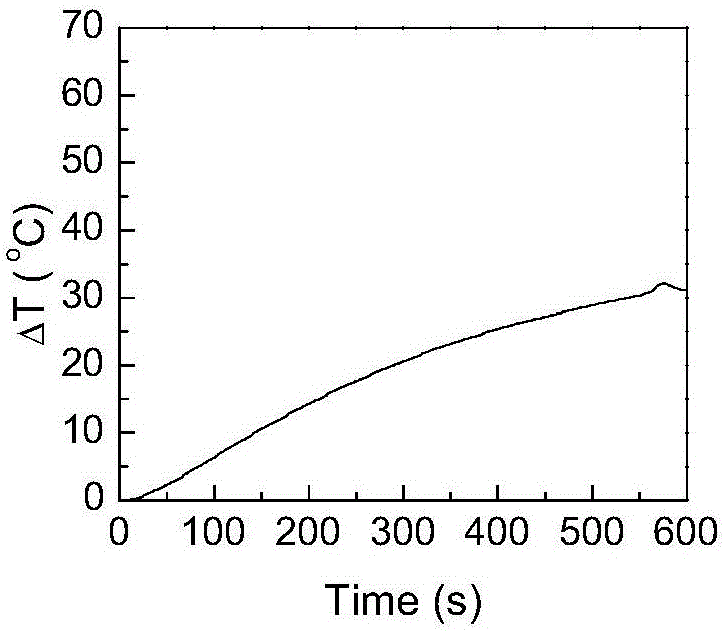

Embodiment 2

[0044] Compared with Example 1, the difference is that the magnetic nanoparticles are Zn 0.5 mn 0.5 Fe 2 o 4 , its addition amount is 0.5%.

[0045] Present embodiment also relates to the preparation method of this bone cement, comprises the steps:

[0046] 1) Place PMMA, MMA and magnetic nanoparticles at 23°C and a relative humidity of 40%-50% for more than 2h,

[0047] 2) Weigh 1.99g of PMMA powder and place it in a crucible, weigh 0.01g of magnetic nanoparticles, and dissolve the magnetic nanoparticles in 1ml of MMA solution, ultrasonically disperse the particles uniformly in the solution, then place the magnetic nanoparticles containing The mixed solution was injected into a crucible filled with PMMA powder and mixed evenly.

[0048] 3) Transfer the mixed mixture to a cylindrical mold with a diameter of 6 mm and a height of 12 mm for about 10 minutes, after it is completely polymerized, demould.

[0049] The present embodiment also relates to the specific application...

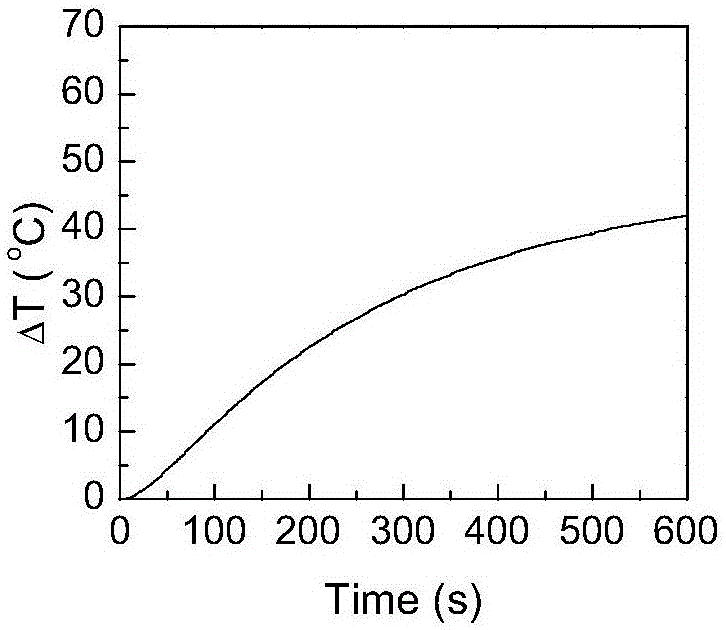

Embodiment 3

[0052] Compared with Example 1, the difference is that the magnetic nanoparticles are Zn 0.7 Fe 2.3 o 4 , its addition amount is 1%.

[0053] Present embodiment also relates to the preparation method of this bone cement, comprises the steps:

[0054] 1) Place PMMA, MMA and magnetic nanoparticles at 23°C and a relative humidity of 40%-50% for more than 2h,

[0055] 2) Weigh 1.99g of PMMA powder and place it in a crucible, weigh 0.02g of magnetic nanoparticles, and dissolve the magnetic nanoparticles in 1ml of MMA solution, ultrasonically disperse the particles uniformly in the solution, then place the magnetic nanoparticles containing The mixed solution was injected into a crucible filled with PMMA powder and mixed evenly.

[0056] 3) Transfer the mixed mixture to a cylindrical mold with a diameter of 6 mm and a height of 12 mm for about 10 minutes, after it is completely polymerized, demould.

[0057] The present embodiment also relates to the specific application of this...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com