Desulfurized flue gas dehumidification and water recovery system and method

A water recovery and flue gas technology, which is applied in chemical instruments and methods, separation methods, lighting and heating equipment, etc., can solve the problems that the latent heat of water vapor cannot be recovered, the thermal efficiency of the boiler system is affected, and the solution dehumidification system is complicated, and the structure is compact. , the effect of saving floor space and high equipment integration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

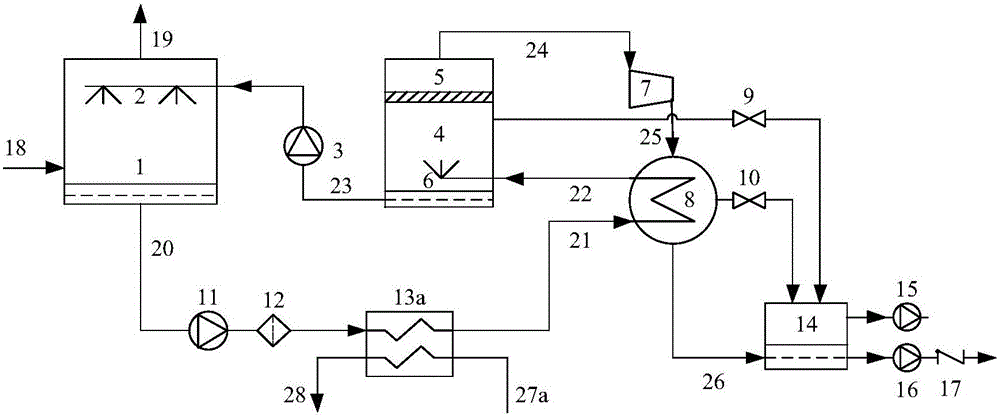

[0053] Embodiment 1: refer to figure 1 As shown, a low-energy desulfurization flue gas dehumidification and water recovery device based on vapor compression heat recovery includes a dehumidifier 1, a first solution pump 3, a flash evaporator 4, a steam compressor 7, a heat exchanger 8, a first electromagnetic Valve 9, second solenoid valve 10, second solution pump 11, solution filter 12, solution-water heat exchanger 13a, pressure regulator reservoir 14, vacuum pump 15, condensate booster pump 16, condensate check valve 17 and connecting pipeline.

[0054] The solution outlet of the dehumidifier 1 is communicated with the solution inlet of the solution-water heat exchanger 13a through the second solution pump 11 and the solution filter 12, and the solution outlet of the solution-water heat exchanger 13a is communicated with the solution inlet of the condensing heat exchanger 8 , the solution outlet of the condensing heat exchanger 8 communicates with the solution spraying dev...

Embodiment 2

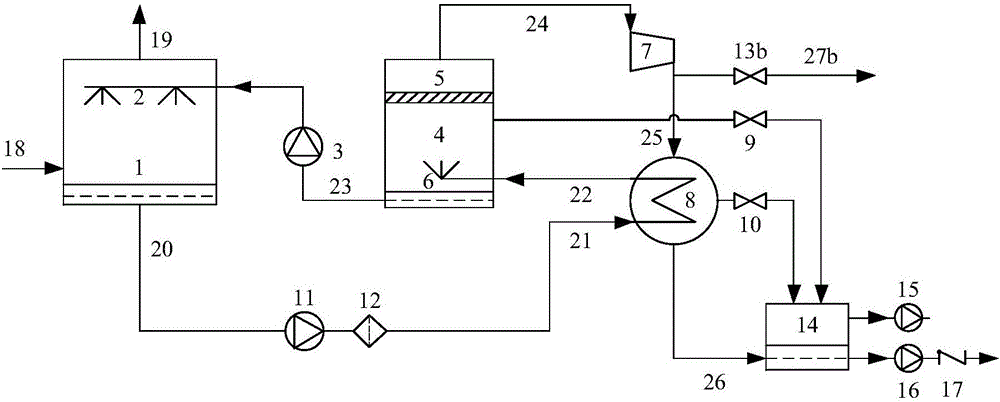

[0062] Embodiment 2: refer to figure 2 As shown, a low-energy desulfurization flue gas dehumidification and water recovery device based on vapor compression heat recovery includes a dehumidifier 1, a first solution pump 3, a flash evaporator 4, a steam compressor 7, a heat exchanger 8, a first electromagnetic Valve 9, second solenoid valve 10, second solution pump 11, solution filter 12, flow regulating valve 13b, steady pressure liquid reservoir 14, vacuum pump 15, condensed water booster pump 16, condensed water one-way valve 17 and connection pipeline.

[0063] The solution outlet of the dehumidifier 1 communicates with the solution inlet of the condensing heat exchanger 8 through the second solution pump 11 and the solution filter 12, and the solution outlet of the condensing heat exchanger 8 is connected with the solution spraying device 6 extending into the lower end of the flasher 4 inner chamber. The solution outlet of the flash evaporator 4 communicates with the sol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com