Method for preparing fluorescent carbon quantum dots through electric spark discharge

A technology of carbon quantum dots and electric sparks, which is applied in the field of electric spark discharge to prepare fluorescent carbon quantum dots, can solve the problems of low efficiency and complicated preparation process of fluorescent carbon quantum dots, and achieve the advantages of convenient operation, simple and reliable equipment, and increased cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

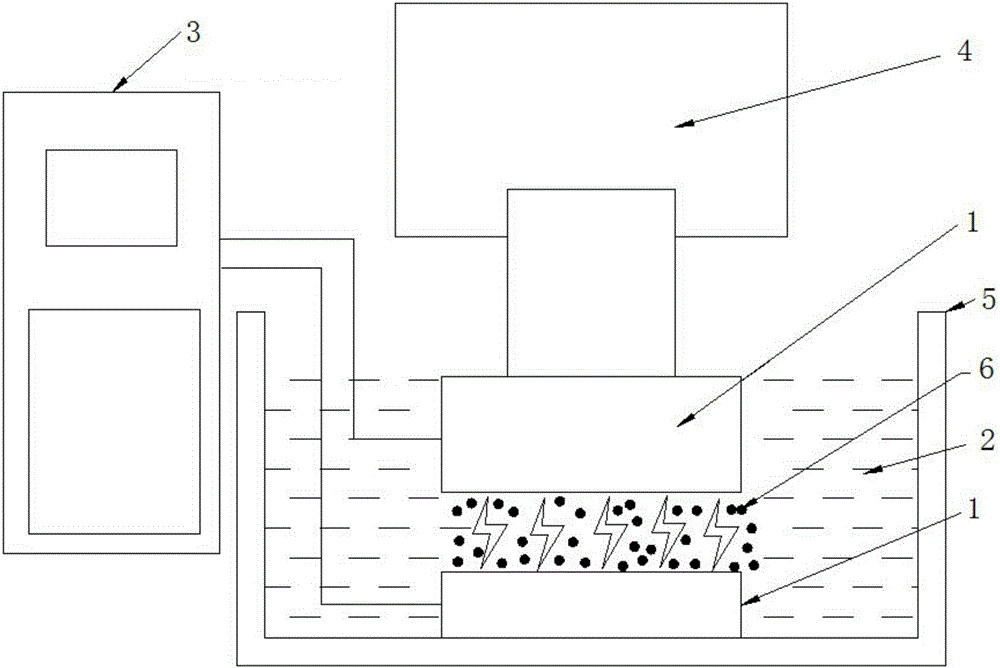

[0025] Example 1, such as figure 1 as shown,

[0026] A method for preparing fluorescent carbon quantum dots by electric spark discharge has the following steps:

[0027] 1. Submerge the upper and lower electrodes 1 of the EDM equipment in the organic medium 2 in the working liquid tank 5, and connect the two electrodes 1 to the two poles of the pulse power supply 3 respectively;

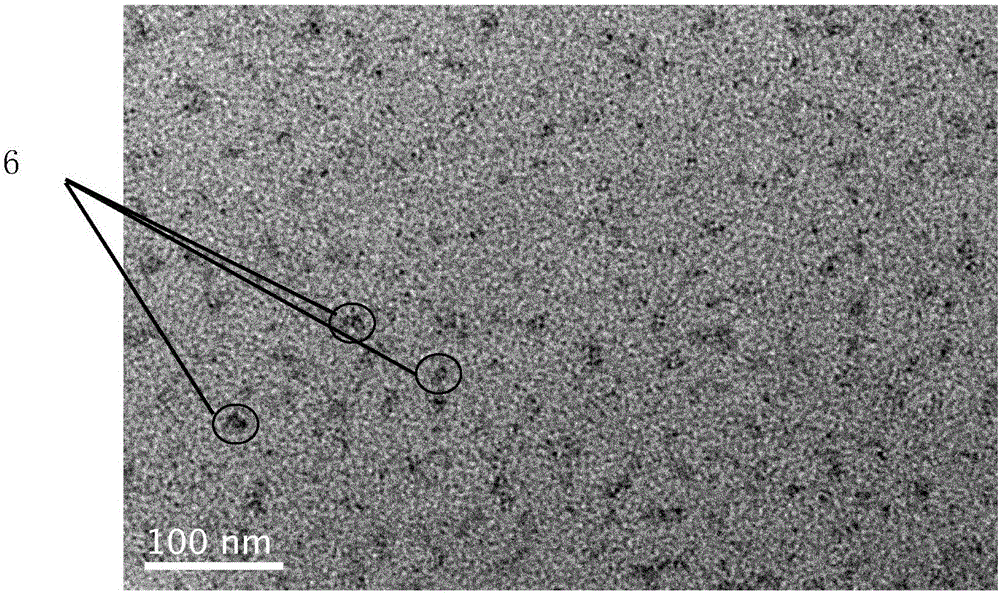

[0028] 2. Control the electrode spacing between the two electrodes 1 through the servo control system 4, so that a continuous pulse discharge is generated between the two electrodes 1, and the organic medium 2 between the electrodes is cracked by the pulse discharge to form carbon atoms. The existence of carbon atoms is unstable, so they will eventually agglomerate to form carbon quantum dots, and the diameter of carbon quantum dots is 1-5nm;

[0029] 3. Since no other impurities are introduced during the preparation process, after the preparation is completed, after standing still for 1-10 hours,...

Embodiment 2

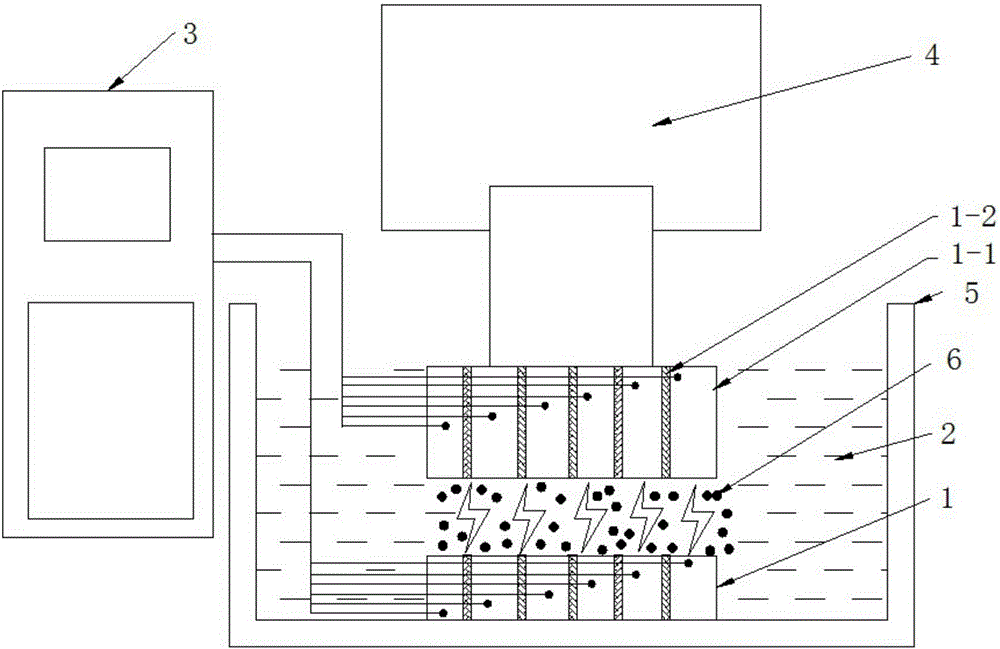

[0036] Example 2, such as figure 2 as shown,

[0037] Compared with Embodiment 1, the difference is that the electrode 1 is an array electrode, and the array electrode is a whole composed of a plurality of electrode units 1-1, and the plurality of electrode units 1-1 are insulated from each other by an insulating material 1-2. Each electrode unit 1-1 forms a pair with one electrode unit 1-1 in another array electrode, and each pair of electrode units 1-1 is respectively connected to two poles of a pulse power supply 3 that is isolated from each other. Electrode unit 1-1 is a high-purity graphite electrode with a carbon content >99.99%.

[0038] Take the organic medium as kerosene as an example to further explain:

[0039] During the preparation process, each electrode has five mutually insulated electrode units 1-1, and each pair of electrode units 1-1 is respectively connected to two poles of a pulse power supply 3 that is isolated from each other. The open circuit voltag...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com