Aluminum alloy automobile hub and preparation method thereof

A technology for automobile hubs and aluminum alloys, which is applied in the manufacture of wheels, wheels, rims, etc., can solve the problems of increased surface friction coefficient of aluminum alloys, high bearing pressure of hubs, and weakened axial tensile performance of rims, etc., to achieve tensile strength Increased strength and elongation, simplification of hub structure, and improved yield of finished products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

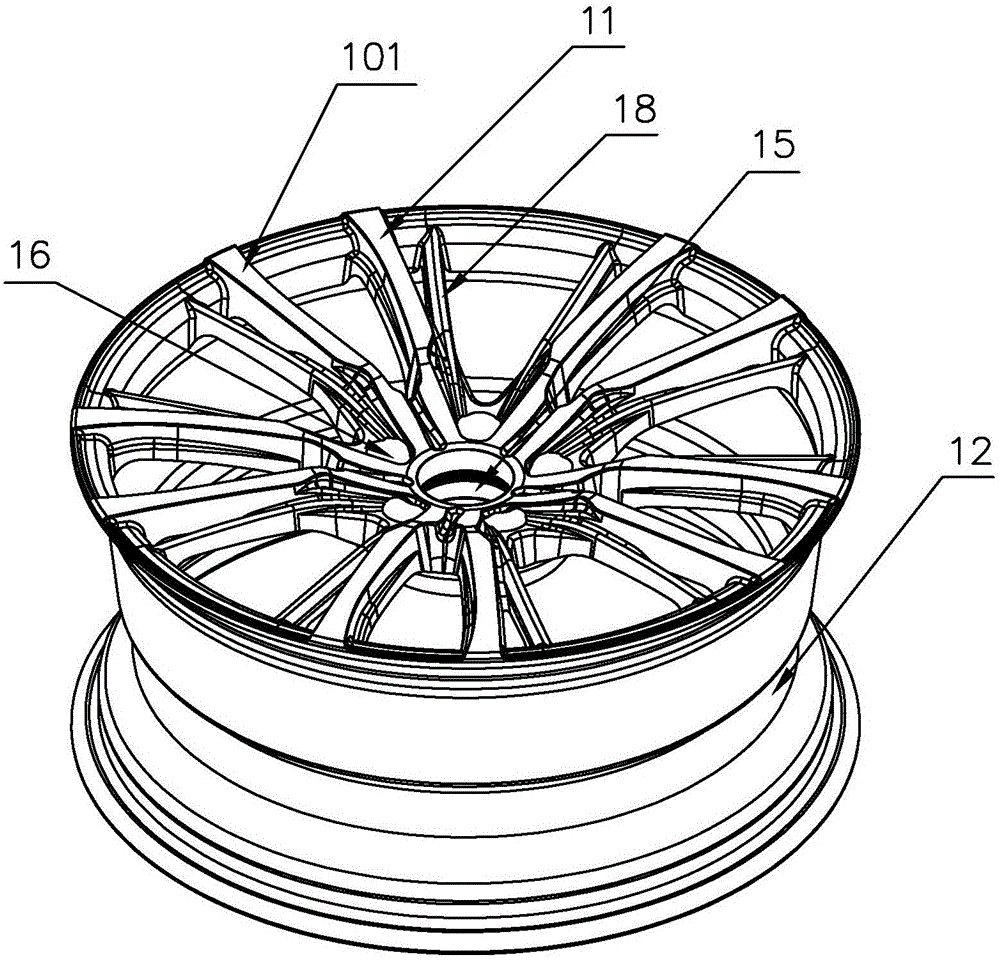

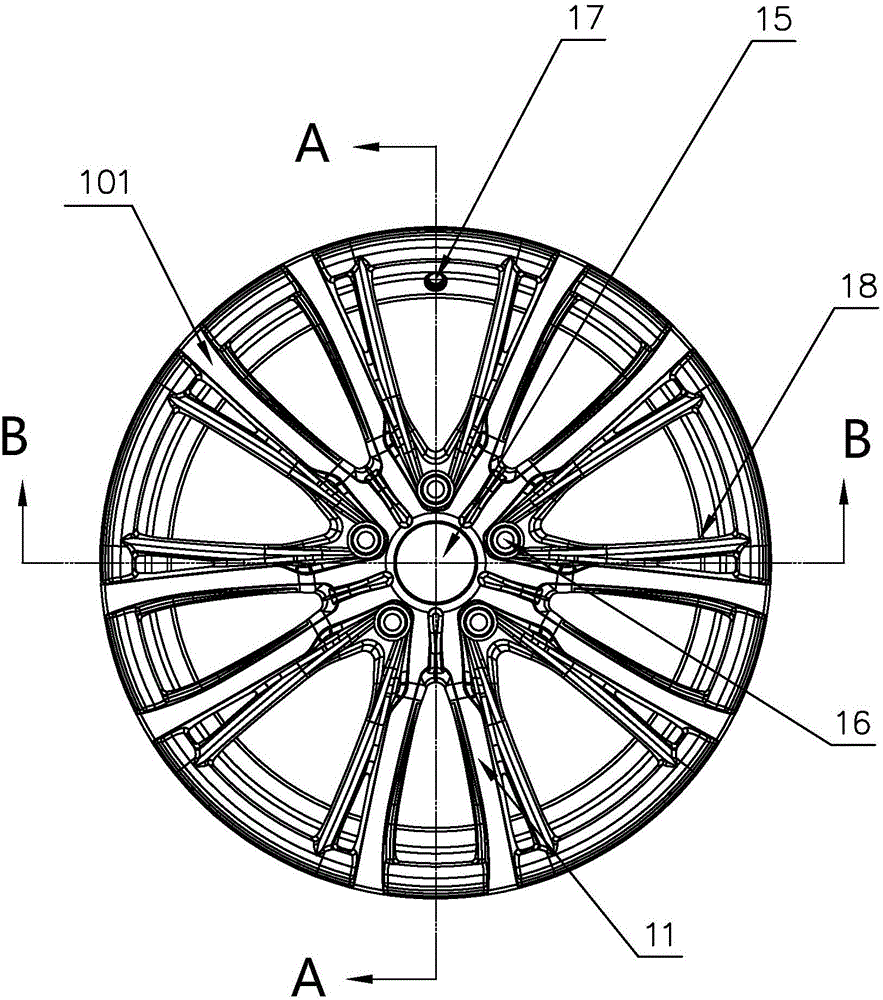

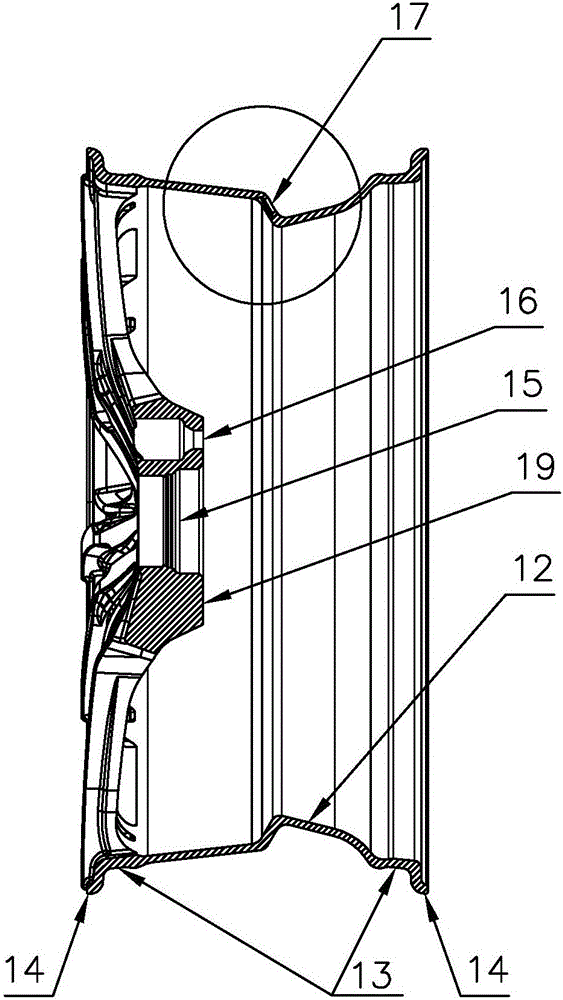

[0038]An aluminum alloy automobile wheel hub, comprising a spoke 11, a rim 12, a bead seat 13, a wheel lip 14, a bayonet 15, a bolt hole 16, and a valve hole 17, the rim 12 is a Z-shaped rim, and the Z-shaped rim includes a Z-shaped rim Initial section 102, reverse transition section 103, Z-shaped extension section 104, Z-shaped initial section 102 connects reverse transition section 103, reverse transition section 103 connects Z-shaped extension section 104, reverse transition section 103 of rim increases Increase the tensile performance of the wheel hub to prevent the wheel hub from cracking due to the excessive width of the rim 12. The two ends of the Z-shaped initial section 102 and the Z-shaped extension section 104 are respectively provided with bead seats 13, and one side of the bead seat 13 is provided with a wheel lip. 14. The reverse transition section 103 in the side wall of the rim 12 is provided with a valve hole 17 .

[0039] The upper part of the rim 12 is provi...

Embodiment 2

[0055] The difference with embodiment 1 is:

[0056] A method for preparing an aluminum alloy automobile wheel hub, comprising the following steps:

[0057] 1) Melting process, melting aluminum ingots, and adding alloy materials, the main components by weight percentage of the final aluminum alloy solution are: Si: 7.0%, Mg: 0.35%, Sr: 0.008%, Ti: 0.12%, Cu: 0.007% , Zn: 0.006%, Ni: 0.008%, Mn: 0.09%, Fe: 0.1%, Cr: 0.007%, Pb: 0.006%, Sn: 0.008%, the total amount of other impurities ≤ 0.005, and the rest is Al.

[0058] After the smelting process is completed, the temperature of the molten aluminum is kept at 705° C., and the low-pressure casting process is carried out.

Embodiment 3

[0060] Compared with embodiment 1, the difference is:

[0061] A method for preparing an aluminum alloy automobile wheel hub, comprising the following steps:

[0062] 2) In the low-pressure casting process, the molten aluminum is transferred to the transfer ladle. The temperature of the molten aluminum is maintained at 720°C, and it is refined and degassed with 99.99% high-purity nitrogen for 10 minutes. After that, the molten aluminum is sampled and analyzed by a sampler. , transferred to the holding furnace of the low-pressure casting machine at 705°C for 1 hour; pressurized to 0.05Mpa, the aluminum liquid enters the liquid riser to rise the liquid, and the liquid rise time is 10s; pressurized to 0.08Mpa until the aluminum liquid fills the mold cavity, and then put The pressure is adjusted to 0.07Mpa for pressure holding, and the holding time is 300s.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com