Antibacterial mildew-resistant ceramic of photocatalyst material and production technology thereof

An antibacterial, mildew-proof, and production process technology, which is applied in the field of ceramic tiles, can solve the problems of fixed adhesion, low pH value, and nanoparticle agglomeration, and achieve high catalytic activity and simple process flow.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 3

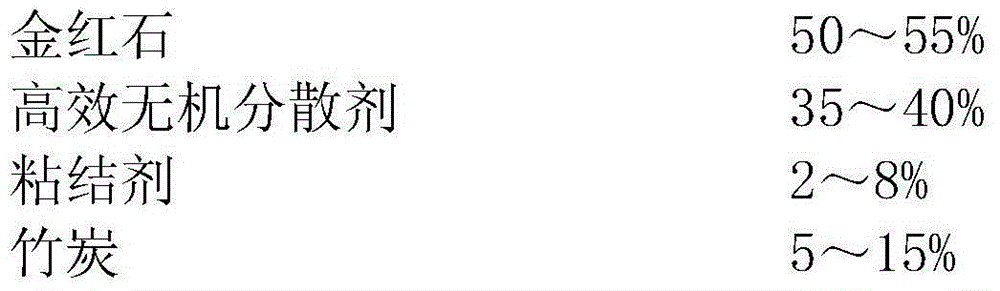

[0042] The technical solution of the present invention is: an antibacterial and mildew-proof ceramic of a photocatalyst material, comprising the following components by weight percentage:

[0043]

[0044] The production process for preparing the antibacterial and mildew-proof ceramics of photocatalyst materials includes the following steps in turn: adopting the step-by-step precipitation low-temperature crystallization method, directly using the intermediate product TiCl 4 The anatase nano-TiO2 colloid with high catalytic activity is prepared, the particle size of the nano-particle is less than 10nm, the pH value of the colloid is about 3.0, and the photocatalytic performance is excellent.

[0045] 1) Put the rutile and bamboo charcoal into the heating container according to the above ratio, use a stirring rod to fully mix the rutile and charcoal powder and pass in chlorine gas (Cl 2 ), at a high temperature of 1050°C, TiCl 4 and a flammable gas, it can be seen that the r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com