An optimized hyodeoxycholic acid crystallization process

A technology of hyodeoxycholic acid and process method, which is applied in the field of crystallization process to refine hyodeoxycholic acid, can solve the problems of prolonging the production cycle and limiting the source of crude products, and achieve the effects of inhibiting decomposition, wide source of raw materials, and low dosage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

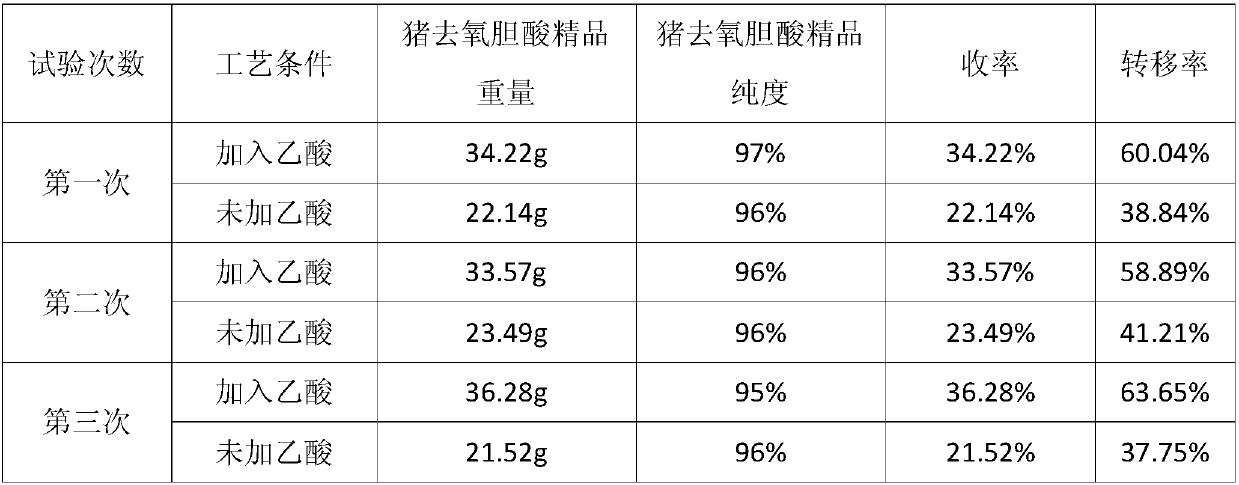

Embodiment 1

[0026] Weigh 100g of magnesium hyodeoxycholic acid salt, the content is 55% based on hyodeoxycholic acid, add 450ml of ethyl acetate, and add 110ml of 50% dilute sulfuric acid solution, stir in a water bath at 60°C until there is no solid magnesium hyodeoxycholic acid Salt exists, discard the lower layer liquid, collect the upper layer liquid and filter, concentrate to 200ml, add 55ml 80% acetic acid solution, stir well, let stand for crystallization, filter to collect crystals, wash with appropriate amount of ethyl acetate, dry, pulverize, 31.64 g of hyodeoxycholic acid refined product was obtained, with a purity of 95%, a yield of 31.64%, and a transfer rate of 54.65%.

[0027] Wherein, yield=weight of refined hyodeoxycholic acid / weight of crude product of hyodeoxycholic acid×100%; transfer rate=(weight of refined product of hyodeoxycholic acid×content of refined product of hyodeoxycholic acid) / (weight of crude product of hyodeoxycholic acid×weight of hyodeoxycholic acid) Ox...

Embodiment 2

[0029] Weigh 200 g of the crude product of hyodeoxycholic acid (free acid), with a content of 73% based on hyodeoxycholic acid, add 1200 ml of ethyl acetate, and add 300 ml of dilute sulfuric acid, and stir in a water bath at 60 ° C until there is no solid hyodeoxycholic acid The crude product exists, discard the lower layer liquid, collect the upper layer liquid and filter, concentrate to 600ml, add 150ml 70% acetic acid solution, stir well, let stand for crystallization, filter to collect crystals, wash with appropriate amount of ethyl acetate, dry, pulverize, 124.23 g of hyodeoxycholic acid refined product was obtained, with a purity of 96%, a yield of 62.12%, and a transfer rate of 81.69%.

Embodiment 3

[0031] Weigh 200 g of hyodeoxycholic acid calcium salt, the content of which is 64% based on hyodeoxycholic acid, add 1000 ml of ethyl acetate, and add 260 ml of dilute sulfuric acid, and stir in a water bath at 70 ° C until no solid hyodeoxycholic acid calcium salt exists. Discard the liquid in the lower layer, collect the liquid in the upper layer and filter, concentrate to 500ml, add 130ml of 99% acetic acid solution, stir well, let stand to crystallize, collect the crystals by filtration, wash with an appropriate amount of ethyl acetate, dry, and pulverize to obtain hyodeoxygen Cholic acid refined product 95.41g, purity 96%, yield 47.70%, transfer rate 71.55%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com