Amide polymer shale inhibitor for drilling fluid and preparation method of shale inhibitor

A technology of shale inhibitor and liquid amide, which is applied in the direction of drilling compositions, chemical instruments and methods, and can solve problems such as poor inhibition effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

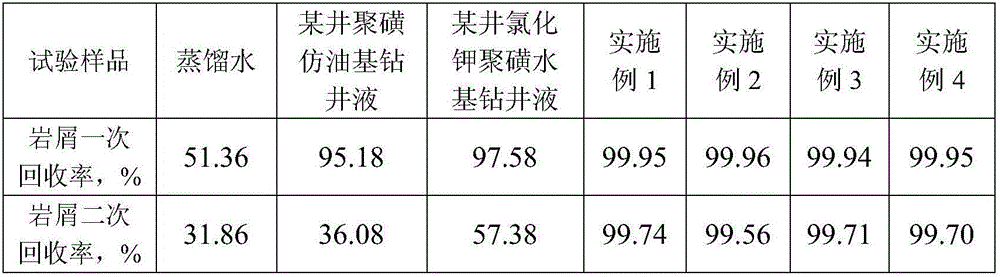

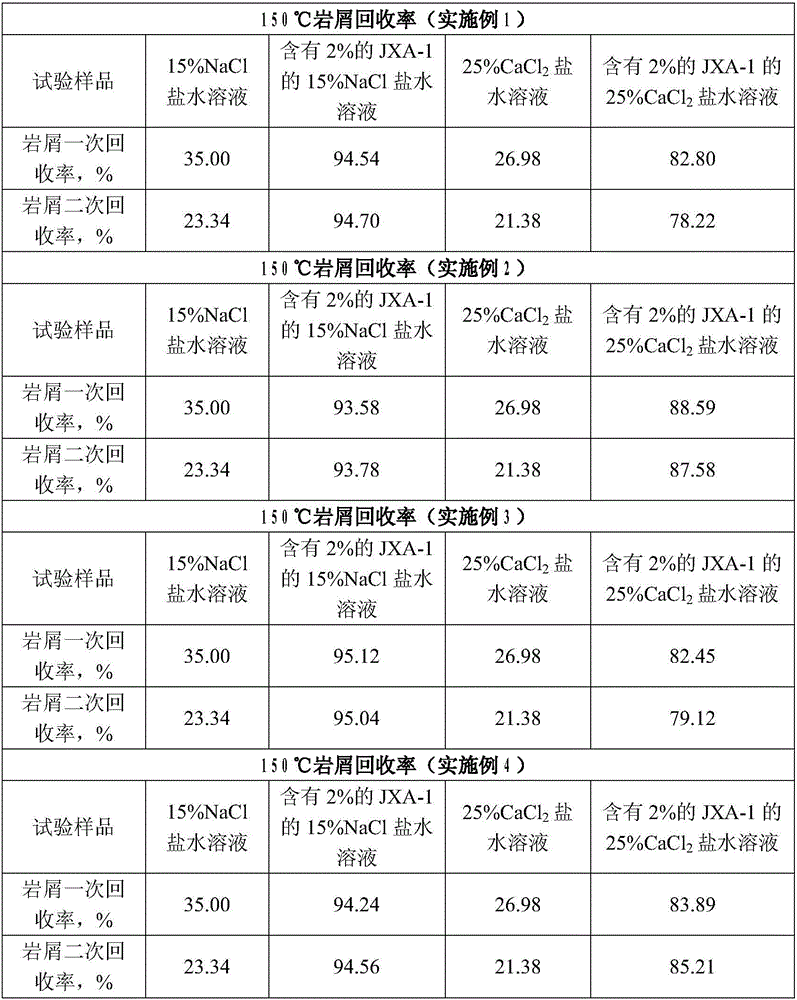

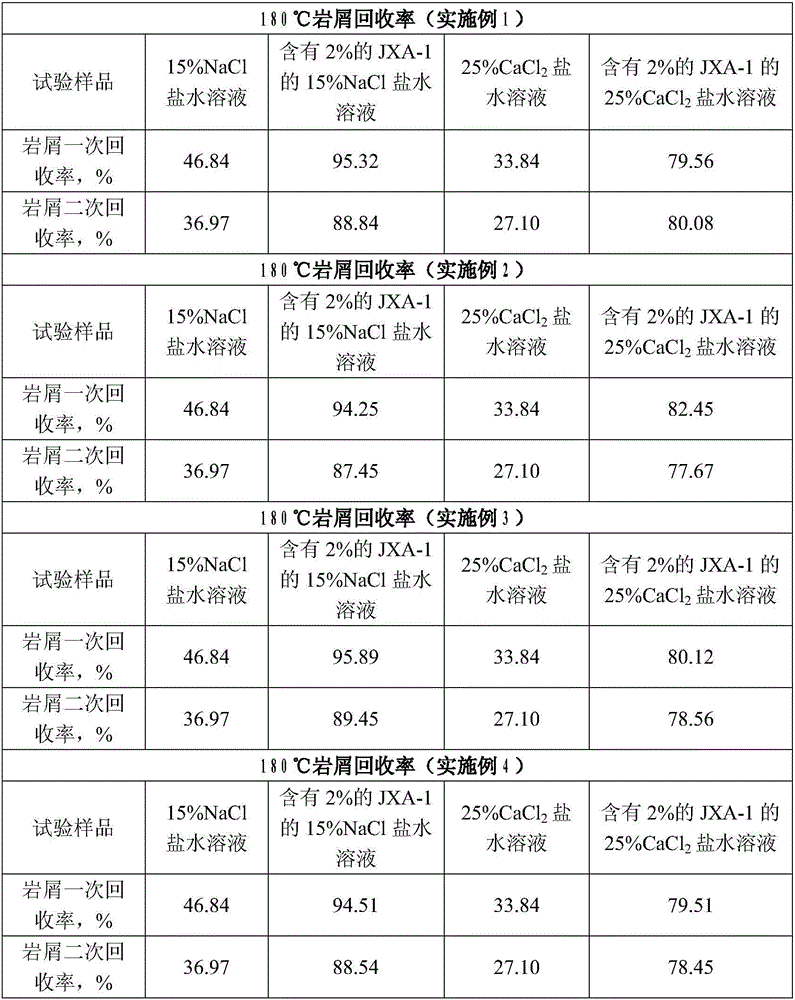

Examples

Embodiment 1

[0020] According to the quality and 100% preparation: acrylamide 10%, 300# liquid wax 5%, cetyl dimethyl benzyl ammonium chloride 10%, dimethyl diallyl ammonium chloride 2%, methacrylic Acyloxyethyltrimethylammonium chloride 30%, acrylic acid 25%, emulsifier 5%, initiator 0.6%, water 40%; among them, the emulsifier is Span60 and Tween80 according to the composition of 1:1, and the initiator is persulfuric acid Ammonium-ethanol; in the reaction kettle, first add the formulated amount of water, add the formulated amount of oil phase dispersion medium 300# liquid wax and emulsifier, and stir at 45°C for 1 hour; add the formulated amount of acrylamide, acrylic acid, Hexadecyl dimethyl benzyl ammonium chloride, dimethyl diallyl ammonium chloride, methacryloyloxyethyl trimethyl ammonium chloride; then add the initiator of the formula amount, and the temperature rises to 80 ℃℃, stir at a constant speed, the rotation speed is about 150r / min, and react for 6h to prepare the shale inhib...

Embodiment 2

[0022] According to the quality and 100% of raw materials: acrylamide 20%, 300# liquid wax 10%, cetyl dimethyl benzyl ammonium chloride 20%, dimethyl diallyl ammonium chloride 8%, methacrylic Acyloxyethyltrimethylammonium chloride 20%, acrylic acid 15%, emulsifier 2%, initiator 0.03%, water 20%; wherein, the emulsifier is Span80 and Tween60 according to the composition of 1:1.5, and the initiator is persulfuric acid Ammonium-pentaerythritol; in the reaction kettle, first add the formulated amount of water, add the formulated amount of oil phase dispersion medium 300# liquid wax and emulsifier, and stir at 60°C for 2 hours; add the formulated amount of acrylamide, acrylic acid, ten Hexaalkyl dimethyl benzyl ammonium chloride, dimethyl diallyl ammonium chloride, methacryloyloxyethyl trimethyl ammonium chloride; then add the amount of initiator formulated, and the temperature rises to 90°C , stirred at a constant speed, the rotation speed was about 200r / min, and reacted for 8 hou...

Embodiment 3

[0024] According to the quality and 100% raw materials: acrylamide 15%, 300# liquid wax 8%, cetyl dimethyl benzyl ammonium chloride 15%, dimethyl diallyl ammonium chloride 5%, methacrylic Acyloxyethyltrimethylammonium chloride 25%, acrylic acid 20%, emulsifier 3%, initiator 0.1%, water 30%; wherein, emulsifier is Span60 and cetyltrimethylammonium bromide according to 1.5 : 1 composition, the initiator is ammonium persulfate-sodium bisulfite; in the reaction kettle, first add the water of formula quantity, add the oil phase dispersion medium 300# liquid wax and emulsifier of formula quantity, and stir at 50 ℃ 1h; add acrylamide, acrylic acid, hexadecyl dimethyl benzyl ammonium chloride, dimethyl diallyl ammonium chloride, methacryloyloxyethyl trimethyl ammonium chloride; Add the formulated amount of initiator, raise the temperature to 90°C, stir at a constant speed at about 300r / min, and react for 7 hours to prepare the shale inhibitor JXA-1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com