A kind of amide polymer shale inhibitor for drilling fluid and preparation method thereof

A technology of shale inhibitor and liquid amide, which is applied in the direction of drilling composition, chemical instruments and methods, etc., and can solve problems such as poor inhibition effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

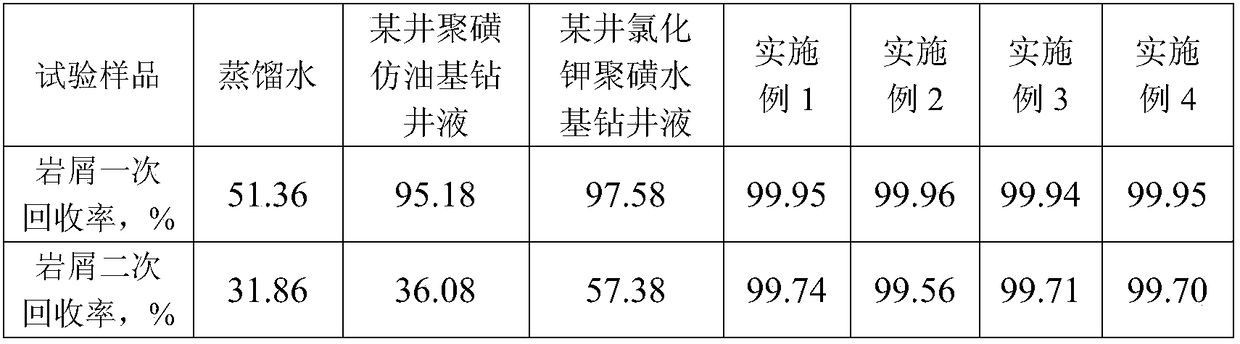

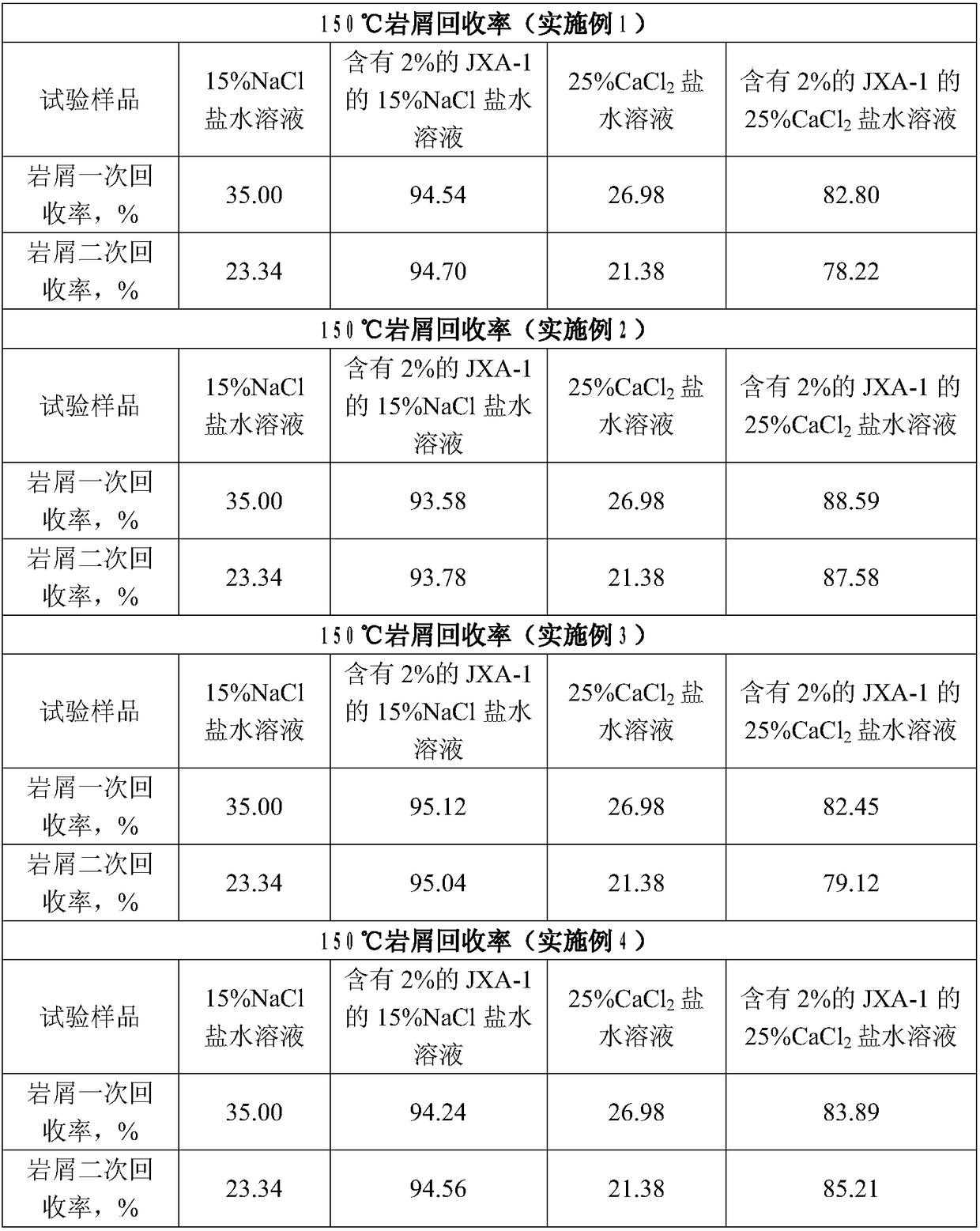

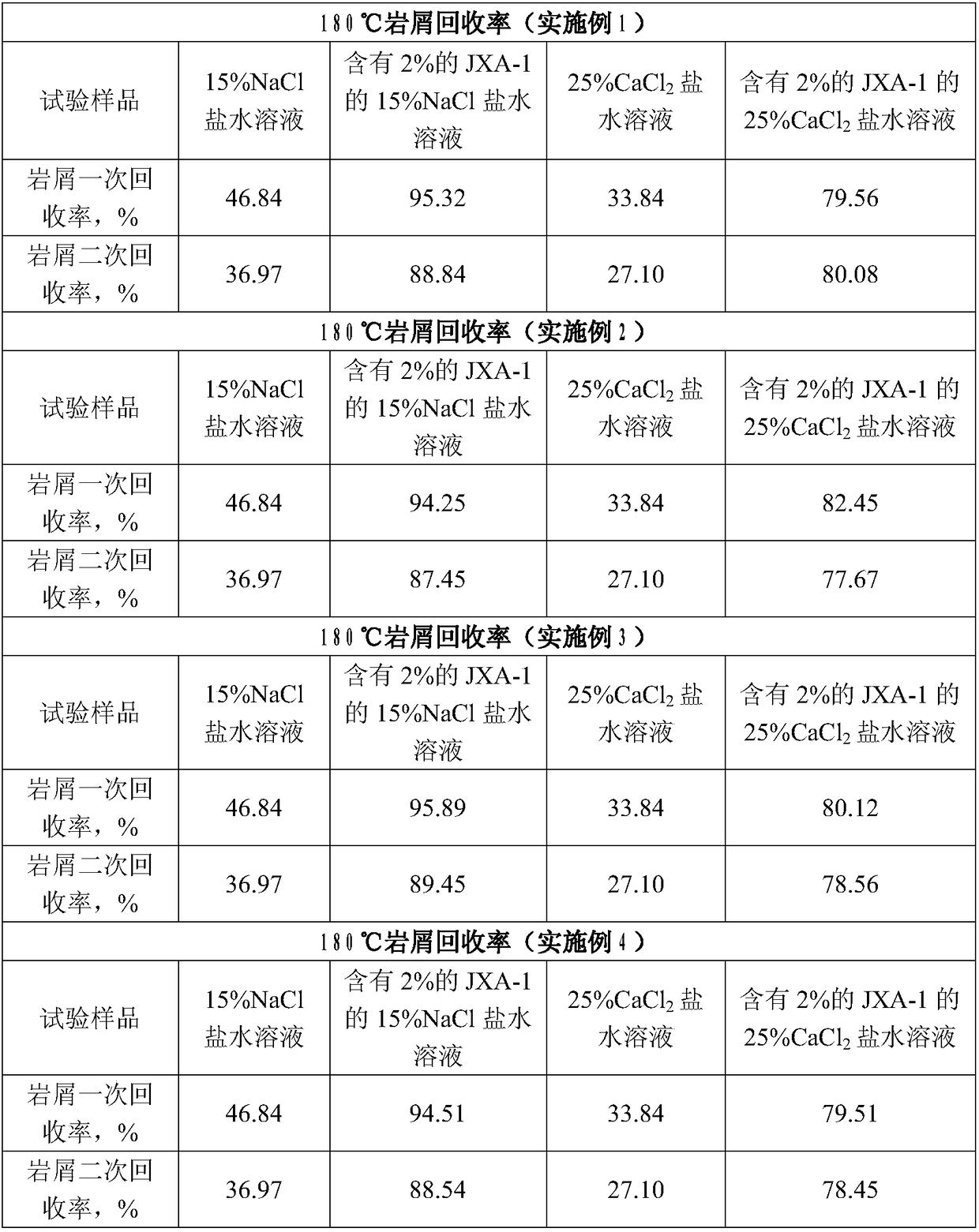

Examples

Embodiment 1

[0020] Prepare materials according to quality and 100%: acrylamide 10%, 300# liquid wax 5%, cetyl dimethyl benzyl ammonium chloride 10%, dimethyl diallyl ammonium chloride 2%, methacrylic acid Acyloxyethyl trimethyl ammonium chloride 30%, acrylic acid 25%, emulsifier 5%, initiator 0.6%, water 40%; among them, the emulsifier is Span60 and Tween80 in a 1:1 composition, and the initiator is persulfuric acid Ammonium-ethanol; In the reactor, first add the formula amount of water, add the formula amount of the oil phase dispersion medium 300# liquid wax and emulsifier, and stir at 45 ℃ for 1h; add the formula amount of acrylamide, acrylic acid, Cetyl dimethyl benzyl ammonium chloride, dimethyl diallyl ammonium chloride, methacryloxyethyl trimethyl ammonium chloride; then add a formula amount of initiator, the temperature rises to 80 ℃ ℃, uniform stirring, speed of about 150r / min, reaction for 6h, to prepare shale inhibitor JXA-1.

Embodiment 2

[0022] Prepare materials according to quality and 100%: acrylamide 20%, 300# liquid wax 10%, cetyl dimethyl benzyl ammonium chloride 20%, dimethyl diallyl ammonium chloride 8%, methyl propylene Acyloxyethyl trimethyl ammonium chloride 20%, acrylic acid 15%, emulsifier 2%, initiator 0.03%, water 20%; among them, the emulsifier is Span80 and Tween60 according to 1:1.5, and the initiator is persulfuric acid Ammonium-pentaerythritol; in the reactor, first add the formula amount of water, add the formula amount of the oil phase dispersion medium 300# liquid wax and emulsifier, and stir at 60 ℃ for 2h; add the formula amount of acrylamide, acrylic acid, ten Hexaalkyl dimethyl benzyl ammonium chloride, dimethyl diallyl ammonium chloride, methacryloxyethyl trimethyl ammonium chloride; then add a formula amount of initiator, the temperature rises to 90 ℃ , Stirring at a uniform speed, rotating speed of about 200r / min, reacting for 8 hours, and preparing shale inhibitor JXA-1.

Embodiment 3

[0024] Prepare materials according to quality and 100%: acrylamide 15%, 300# liquid wax 8%, cetyl dimethyl benzyl ammonium chloride 15%, dimethyl diallyl ammonium chloride 5%, methyl propylene Acyloxyethyl trimethyl ammonium chloride 25%, acrylic acid 20%, emulsifier 3%, initiator 0.1%, water 30%; among them, the emulsifier is Span60 and cetyltrimethylammonium bromide according to 1.5 :1 composition, the initiator is ammonium persulfate-sodium bisulfite; in the reactor, first add the formula amount of water, add the formula amount of the oil phase dispersion medium 300# liquid wax and emulsifier, and stir at 50 ℃ 1h; add formula amount of acrylamide, acrylic acid, cetyl dimethyl benzyl ammonium chloride, dimethyl diallyl ammonium chloride, methacryloxyethyl trimethyl ammonium chloride; then Add a formula amount of initiator, raise the temperature to 90°C, stir at a constant speed, rotate at about 300r / min, and react for 7 hours to prepare shale inhibitor JXA-1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com