Maillard reaction-based vegetable protein nano-gel and preparation thereof

A technology of plant protein and nanogel, which is applied in the field of food nanogel, can solve the problems that have not been discovered in the research of nanogel, and achieve the effects of environmental friendliness, low cost and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

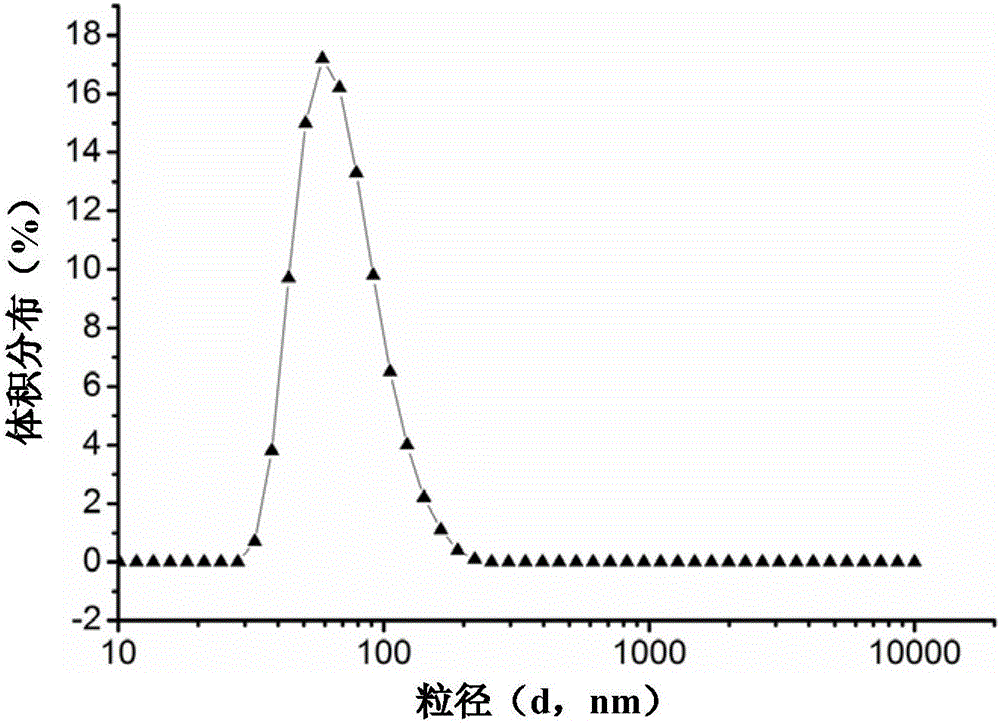

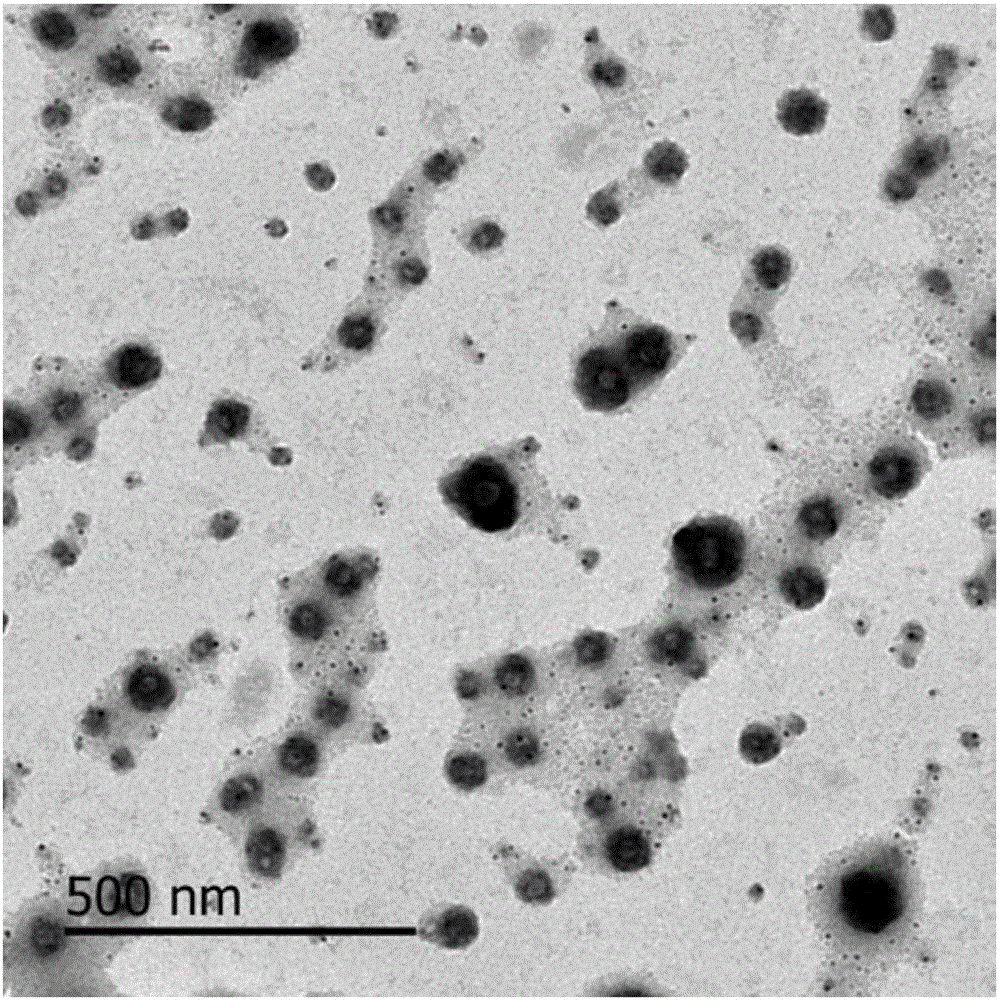

[0032] Embodiment 1: the preparation of the plant protein nanogel based on Maillard reaction

[0033] Dissolve soybean 7S globulin and dextran with a mass ratio of 1:1 in water to a concentration of 0.2 g / mL, stir and disperse for 2 h, adjust the pH to 6.8 with dilute hydrochloric acid, and freeze-dry to obtain a powder. Place the dry powder in a container with a saturated KBr solution at the bottom (keep the relative humidity at 79%), react at 60°C for 4 days, and then mix the reacted powder with a ratio of 1:10 (w / v, mg / mL) The ratio was added to water to redissolve, centrifuged at 10,000g at 25°C for 15 minutes, the unreacted raw material in the lower layer was removed, and the supernatant was freeze-dried, and the obtained powder was soybean 7S globulin-dextran covalent complex. Dissolve the above powder in water to make a homogeneous solution with a concentration of 1 mg / mL, adjust the pH of the solution to an isoelectric point of 4.8 with 0.1 mol / L HCl solution, heat in ...

Embodiment 2

[0034] Embodiment 2: Preparation of plant protein nanogel based on Maillard reaction

[0035] Dissolve soybean 7S globulin and dextran with a mass ratio of 1:3 in water to make the concentration of soybean protein 0.1 g / mL, stir and disperse for 6 hours, adjust the pH to 7.0 with dilute hydrochloric acid, and spray dry to obtain powder. Place the dry powder in a container with a saturated KBr solution at the bottom (keep the relative humidity at 68%), react at 60°C for 4 days, and then mix the reacted powder with a ratio of 1:10 (w / v, mg / mL) The ratio was added to water to redissolve, centrifuged at 10,000g at 25°C for 15 minutes, the unreacted raw material in the lower layer was removed, and the supernatant was freeze-dried, and the obtained powder was soybean 7S globulin-dextran covalent complex. Dissolve the above powder in water to make a homogeneous solution with a concentration of 1 mg / mL, adjust the pH of the solution to an isoelectric point of 4.8 with 0.1 mol / L HCl so...

Embodiment 3

[0036] Embodiment 3: the preparation of the plant protein nanogel based on Maillard reaction

[0037] Dissolve pea protein and dextran with a mass ratio of 1:1 in water so that the concentration of soybean protein is 1 g / mL, stir and disperse for 2 h, adjust the pH to 6.9 with dilute hydrochloric acid, and freeze-dry to obtain powder. Place the dry powder in a container with a saturated KBr solution at the bottom (keep the relative humidity at 65%), react at 50°C for 6 days, and then mix the reacted powder with a ratio of 1:10 (w / v, mg / mL) The ratio was added to water to redissolve, centrifuged at 10000g at 25°C for 15min, the unreacted raw material in the lower layer was removed, the supernatant was freeze-dried, and the obtained powder was the pea protein-dextran covalent complex. Dissolve the above powder in water to prepare a uniform solution with a concentration of 5 mg / mL, adjust the pH of the solution to an isoelectric point of 5.0 with 0.1 mol / L HCl solution, heat in a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com