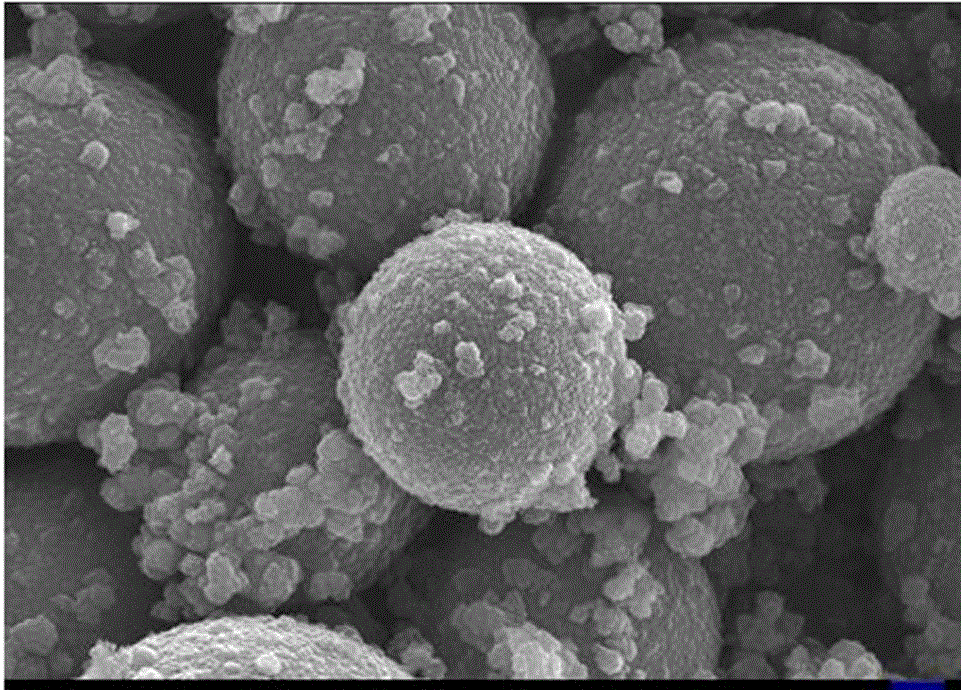

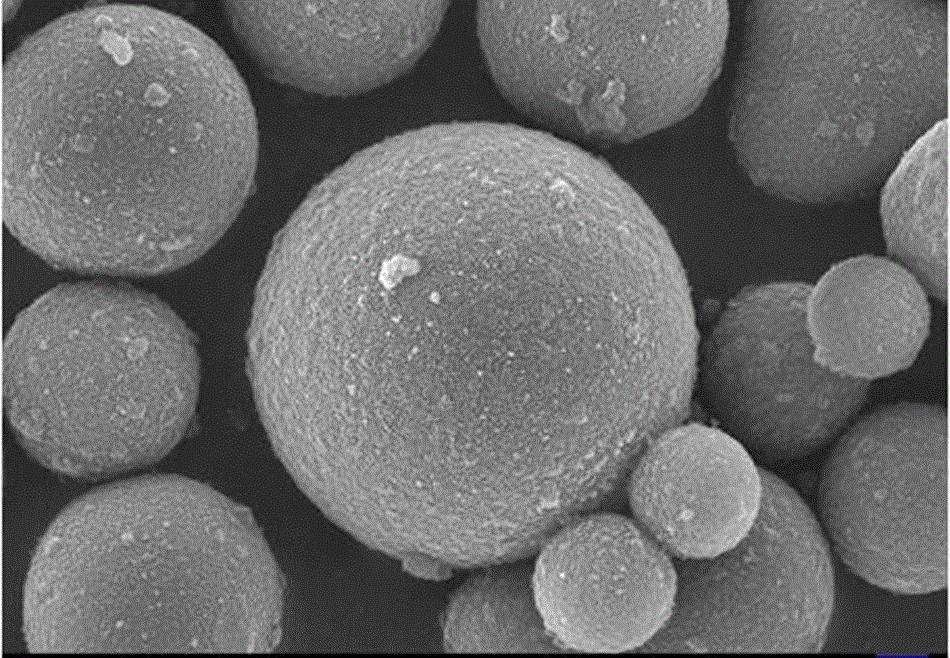

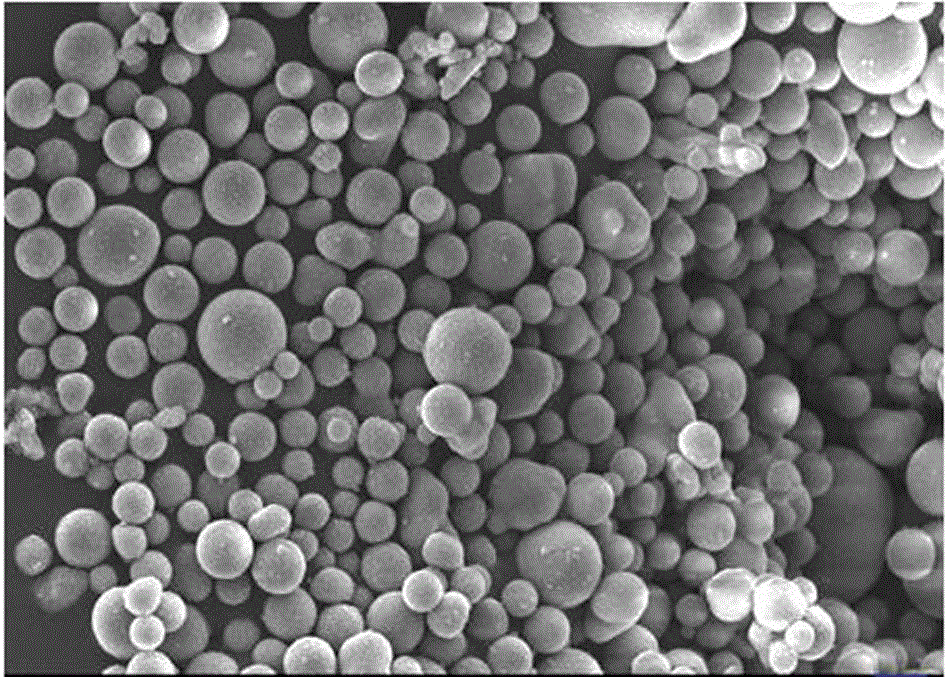

Prussian-blue spherical pigments for cosmetics and preparation method thereof

A technology for Prussian blue and cosmetics, applied in the field of Prussian blue spherical pigment for cosmetics and its preparation, can solve the problems of peeling off of the coating layer, low coating conversion rate, poor pigment effect, etc. The effect of low oil absorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] The preparation method of this Prussian blue spherical pigment comprises the following steps:

[0047] A. Weigh 50 g of solid spherical SiO with an average particle size of 5 μm 2 , put it into a reaction kettle with a volume of 2L, add 800ml of deionized water, and stir to make it evenly dispersed to form a suspension;

[0048] B. Heat the suspension treated in step A to 75°C, adjust the pH value of the suspension to 5.5 with dilute hydrochloric acid, and then slowly add 0.5mol / L AlCl dropwise under constant temperature stirring 3 Solution 40ml, and 20% sodium hydroxide was added dropwise during this process to keep the pH value constant; when the solution was added, continue to stir at constant temperature for 20-30 min;

[0049] C. Keep the temperature of the suspension treated in step B at 75°C, adjust its pH value to 3.2, and then add FeCl while stirring at constant temperature 3 solution, K 4 Fe(CN) 6 solution, controlling the flow of both solutions to keep...

Embodiment 2

[0054] The preparation method of this Prussian blue spherical pigment comprises the following steps:

[0055] A. Weigh 50 g of solid spherical SiO with an average particle size of 5 μm 2 , put it into a reaction kettle with a volume of 2L, add 800ml of deionized water, and stir to make it evenly dispersed to form a suspension;

[0056] B. Heat the suspension treated in step A to 65°C, adjust the pH value of the suspension to 1.5 with dilute hydrochloric acid, and then slowly add 0.5 wt% SnCl dropwise under constant temperature stirring 4 Solution 30ml, and in this process, dropwise add 20% sodium hydroxide to keep pH value constant; When said SnCl 4 After adding the solution, continue to stir at constant temperature for 20-30 min;

[0057] C. Heat the suspension treated in step B to 75°C, adjust the pH value of the suspension to 5.5 with dilute hydrochloric acid, and then slowly add 0.5mol / L AlCl dropwise under constant temperature stirring 3 Solution 40ml, and 20% sodiu...

Embodiment 3

[0063] The preparation method of this Prussian blue spherical pigment comprises the following steps:

[0064] A. Weigh 150 g of solid spherical SiO with an average particle size of 2 μm 2 , put it into a reaction kettle with a volume of 2L, add 800ml of deionized water, and stir to make it evenly dispersed to form a suspension;

[0065] B. Heat the suspension treated in step A to 65°C, adjust the pH value of the suspension to 1.5 with dilute hydrochloric acid, and then slowly add 0.5 wt% SnCl dropwise under constant temperature stirring 4 Solution 60ml, and in this process, dropwise add 20% sodium hydroxide to keep pH value constant; When said SnCl 4 After adding the solution, continue to stir at constant temperature for 20-30 min;

[0066] C. Heat the suspension treated in step B to 75°C, adjust the pH value of the suspension to 5.5 with dilute hydrochloric acid, and then slowly add 0.5mol / L AlCl dropwise under constant temperature stirring 3 Solution 80ml, and 20% sodi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com