Silicate phosphor and preparation method and application thereof

A phosphor and silicate technology, applied in chemical instruments and methods, luminescent materials, etc., can solve the problems of poor product particle size uniformity and morphology, surface damage of phosphor particles, and strict requirements for reaction atmosphere, etc. The effect of crystal structure, crystal quality improvement, and emission intensity improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

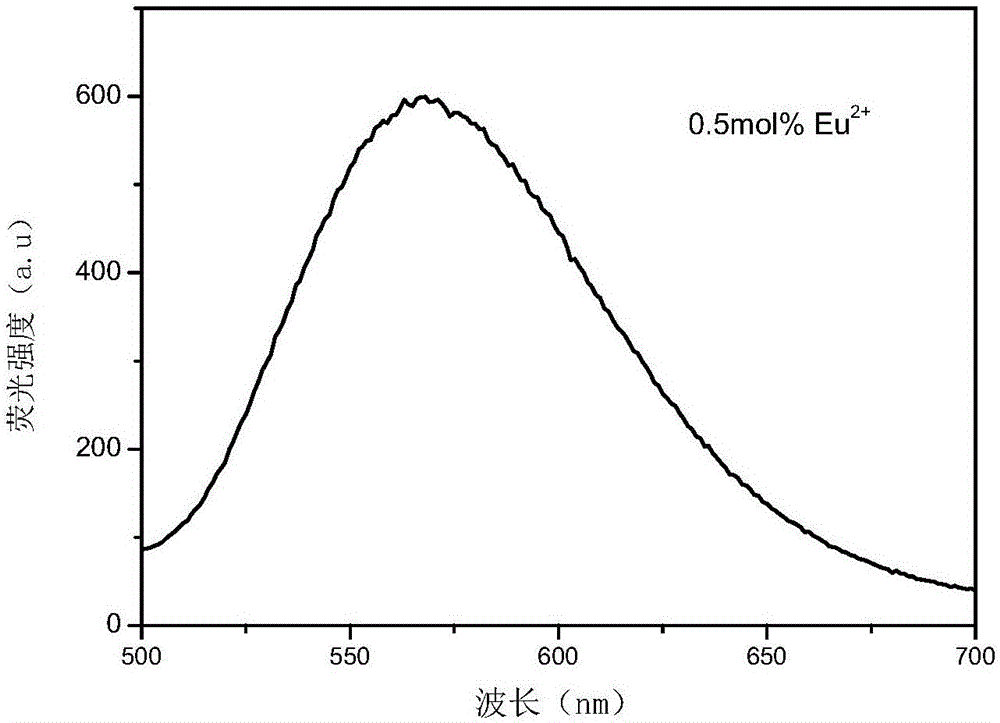

Embodiment 1

[0044] Selected raw materials: Li 2 CO 3 (A·R), SrCO 3 (A·R), Eu 2 o 3 (A·R), Ag nano, tetraethyl orthosilicate (TEOS), HNO 3 (A R), absolute ethanol (A R), its composition and content according to the chemical formula Li 2 Sr 1-x-y SiO 4 :xEu 2+ , yRE 3+ A configuration was performed with x=0.5 mol%, y=0 mol%. Its process steps are:

[0045] (1) configure metal ion solution, according to stoichiometry, weigh the mass to get 1 / 75 of the formula molar mass, and the formula molar mass is 1molLi 2 m 1-x-y SiO 4 When taking x=0.5mol%, y=0mol%, then weigh Li respectively 2 CO 3 =1.0345g, SrCO 3 =1.9586g, (C 2 h 5 O) 4 Si=2.7788g, Eu 2 o 3 =0.0117g raw material, dissolve SrCO with 3-4ml nitric acid with a concentration of 65%~68% 3 , to obtain metal ion solution A.

[0046] (2) Mix concentrated nitric acid with a certain amount of deionized water to form dilute nitric acid with a concentration of (1-2) mol / L; dissolve Eu with dilute nitric acid 2 o 3 、Sm 2 o...

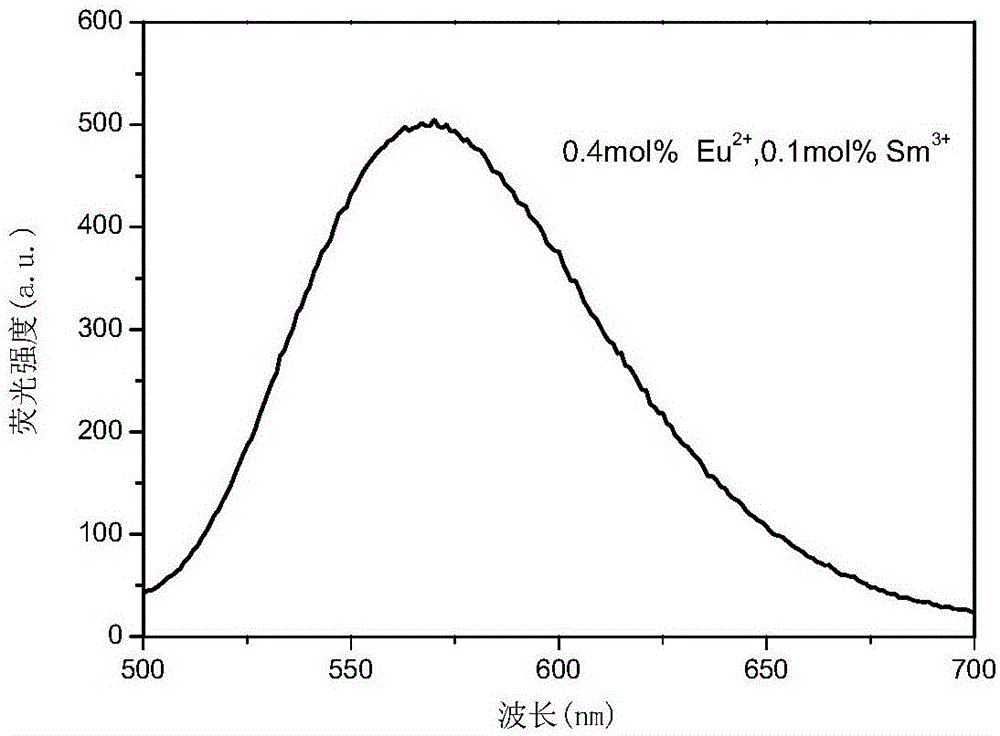

Embodiment 2

[0054] Selected raw materials: Li 2 CO 3 (A·R), SrCO 3 (A·R), Eu 2 o 3 (A·R), Sm 2 o 3 , Ag nano, tetraethyl orthosilicate (TEOS), HNO 3 (A R), absolute ethanol (A R), its composition and content according to the chemical formula Li 2 Sr 1-x-y SiO 4 :xEu 2+ ,yRE 3 + , RE 3+ =Sm to configure, x=0.4mol%, y=0.1mol%. Its process steps are:

[0055] (1) configure metal ion solution, according to stoichiometry, weigh the mass to get 1 / 75 of the formula molar mass, and the formula molar mass is 1molLi 2 m 1-x-y SiO 4 When taking x=0.4mol%, y=0.1mol%, then weigh Li respectively 2 CO 3 =1.0345g, SrCO 3 =1.9586g, (C 2 h 5 O) 4 Si=2.7788g, Eu 2 o 3 =0.0094g, Sm 2 o 3 =0.0023g raw material, dissolve SrCO with 3-4ml nitric acid with a concentration of 65%~68% 3 , to obtain metal ion solution A.

[0056] (2) Mix concentrated nitric acid with a certain amount of deionized water to form dilute nitric acid with a concentration of (1-2) mol / L; dissolve Eu with dilute...

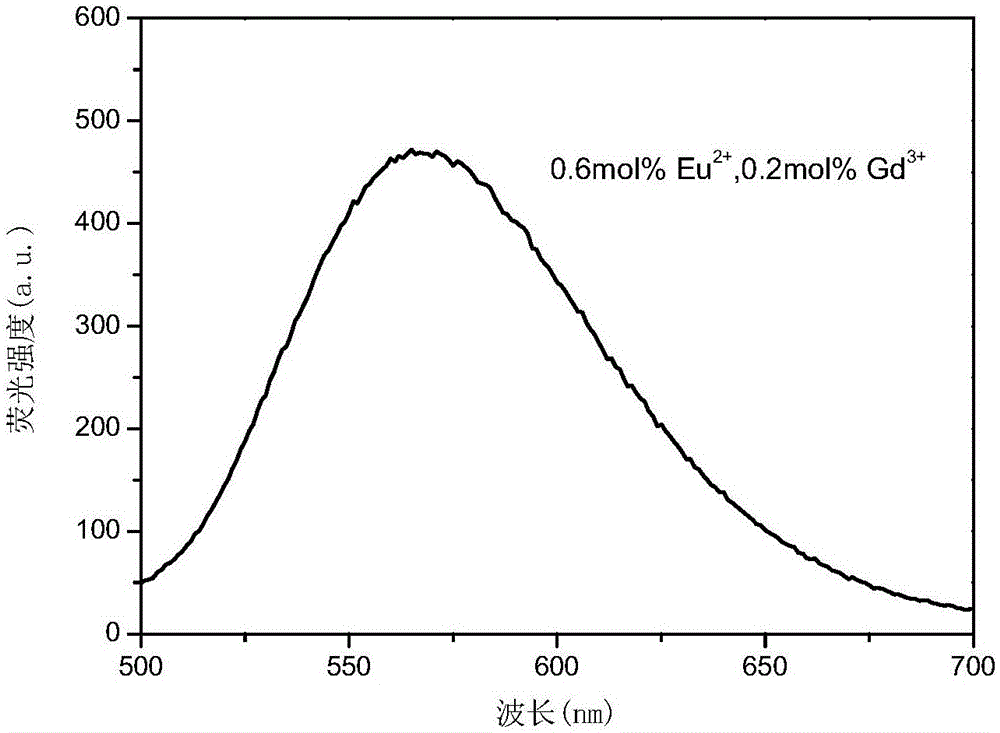

Embodiment 3

[0064] Selected raw materials: Li 2 CO 3 (A·R), SrCO 3 (A·R), Eu 2 o 3 (A·R), Gd 2 o 3 , Ag nano, tetraethyl orthosilicate (TEOS), HNO 3 (A R), absolute ethanol (A R), its composition and content according to the chemical formula Li 2 Sr 1-x-y SiO 4 :xEu 2+ , yRE 3 + , RE 3+ =Gd for configuration, x=0.6 mol%, y=0.2 mol%. Its process steps are:

[0065] (1) configure metal ion solution, according to stoichiometry, weigh the mass to get 1 / 75 of the formula molar mass, and the formula molar mass is 1molLi 2 m 1-x-y SiO 4 When taking x=0.6mol%, y=0.2mol%, then weigh Li respectively 2 CO 3 =1.0345g, SrCO 3 =1.9527g, (C 2 h 5 O) 4 Si=2.7788g, Eu 2 o 3 =0.0141g, Gd 2 o 3 =0.0048g raw material, dissolve SrCO with 3-4ml nitric acid with a concentration of 65%~68% 3 , to obtain metal ion solution A.

[0066] (2) Mix concentrated nitric acid with a certain amount of deionized water to form dilute nitric acid with a concentration of (1-2) mol / L; dissolve Eu wit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| The fluorescence intensity | aaaaa | aaaaa |

| The fluorescence intensity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com