A biodiesel compound emulsifier and its preparation method and application thereof

A technology for compounding emulsifier and biodiesel, which is used in biofuels, petroleum industry, liquid carbon-containing fuels, etc., can solve the problems of low volatility, poor volatility and high viscosity, prevent oil-water separation, maintain stability, The effect of enhancing stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

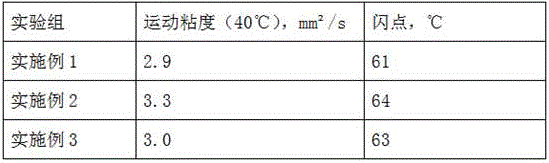

Embodiment 1

[0016] The present embodiment provides a biodiesel compound emulsifier, the formula of which is composed of the following components: 70 parts by weight of biodiesel, 3 parts of compound emulsifier, and 40 parts of water; the compound emulsifier is by weight Including 28% fatty alcohol polyoxyethylene ether AEO-3, 15% carboxymethyl cellulose, 9% dimethyl phosphite, 18% fumaric acid and 30% sorbitol.

[0017] The preparation method of the compound emulsifier is to heat the sorbitol to 100°C, add the fatty alcohol polyoxyethylene ether AEO-3, carboxymethyl cellulose, and fumaric acid, and place it in a sealed container Heat to 150° C. under a pressure of 0.5 MPa and keep it for 35 minutes; release the pressure of the container and lower the temperature to 50° C., add dimethyl butenedioate and keep it for 60 minutes to obtain the compound emulsifier.

[0018] An application of a biodiesel compound emulsifier to prepare microemulsified biodiesel, comprising the following steps: ad...

Embodiment 2

[0020] The present embodiment provides a biodiesel compound emulsifier, the formula of which is composed of the following components: 78 parts by weight of biodiesel, 2 parts of compound emulsifier, and 50 parts of water; the compound emulsifier is by weight Including 28% fatty alcohol polyoxyethylene ether AEO-3, 15% carboxymethyl cellulose, 9% dimethyl phosphite, 18% fumaric acid and 30% sorbitol.

[0021] The preparation method of the compound emulsifier is to heat the sorbitol to 100°C, add the fatty alcohol polyoxyethylene ether AEO-3, carboxymethyl cellulose, and fumaric acid, and place it in a sealed container Heat to 150° C. under a pressure of 0.7 MPa and keep it for 30 minutes; release the pressure of the container and lower the temperature to 50° C., add dimethyl butenedioate and keep it for 60 minutes to obtain the compound emulsifier.

[0022] The micro-emulsion diesel oil prepared in this example is prepared by adding various raw materials into a mechanical mixer...

Embodiment 3

[0024] The present embodiment provides a biodiesel compound emulsifier, the formula of which is composed of the following components: 65 parts by weight of biodiesel, 5 parts of compound emulsifier, and 32 parts of water; Including 28% fatty alcohol polyoxyethylene ether AEO-3, 15% carboxymethyl cellulose, 9% dimethyl phosphite, 18% fumaric acid and 30% sorbitol.

[0025] The preparation method of the compound emulsifier is to heat the sorbitol to 100°C, add the fatty alcohol polyoxyethylene ether AEO-3, carboxymethyl cellulose, and fumaric acid, and place it in a sealed container Heat to 150°C under a pressure of 0.6MPa, and keep it for 40 minutes; release the pressure of the container and lower the temperature to 50°C, add dimethyl butenedioate, and keep it for 60 minutes to obtain the compound emulsifier.

[0026] The preparation method of the microemulsified biodiesel in this example is consistent with Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com